Robot assembly line practical training platform

A training platform and robot technology, which is applied in the direction of instruments, simulators, space navigation equipment, etc., can solve the problems of restricting the training of talents on the robot assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

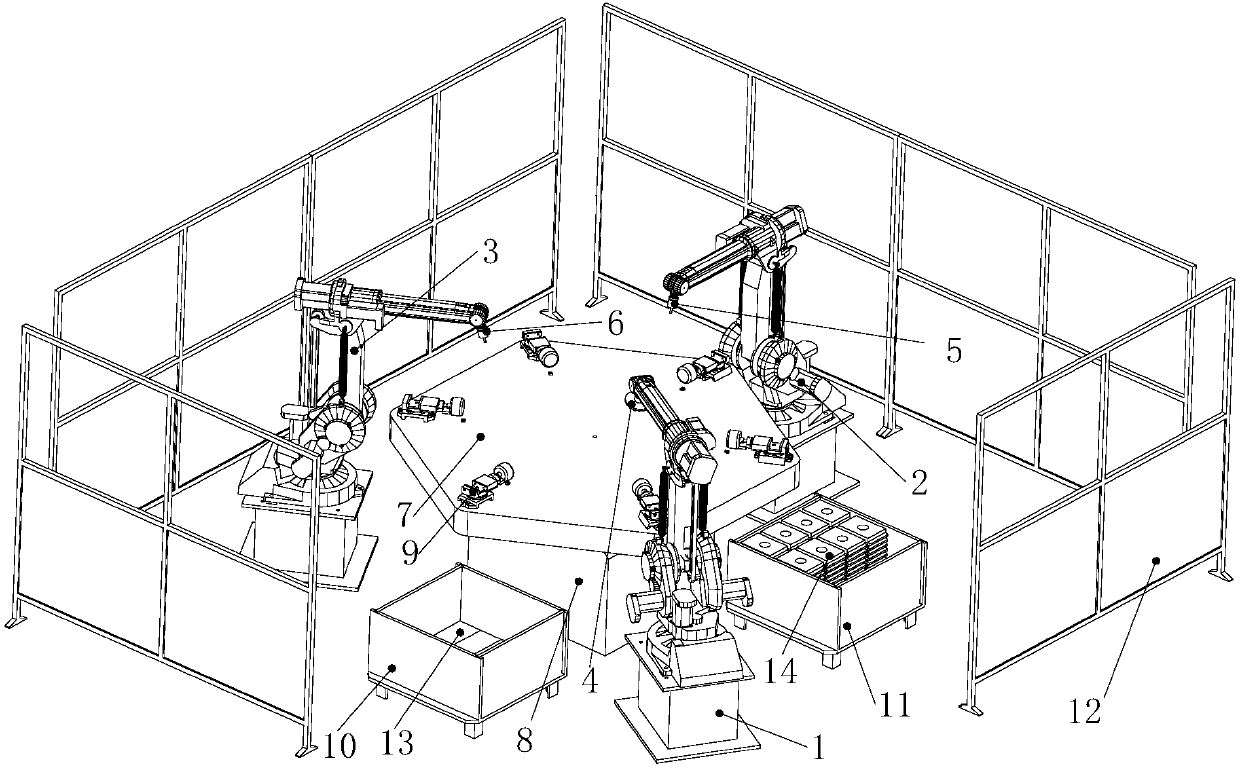

[0015] like Figure 1-2 As shown, in the preferred embodiment of the robot assembly line training platform of the present invention, it includes three robot bodies (1, 2, 3), a suction cup (4), a drill tool (5), a grinding tool (6), a turntable ( 7), positioner (8), clamping vise (9), original box (10), finished product box (11), fence (12); the turntable (7) is a regular hexagon, and the hexagons are all open There are threaded holes, and all are connected with clamping vise (9).

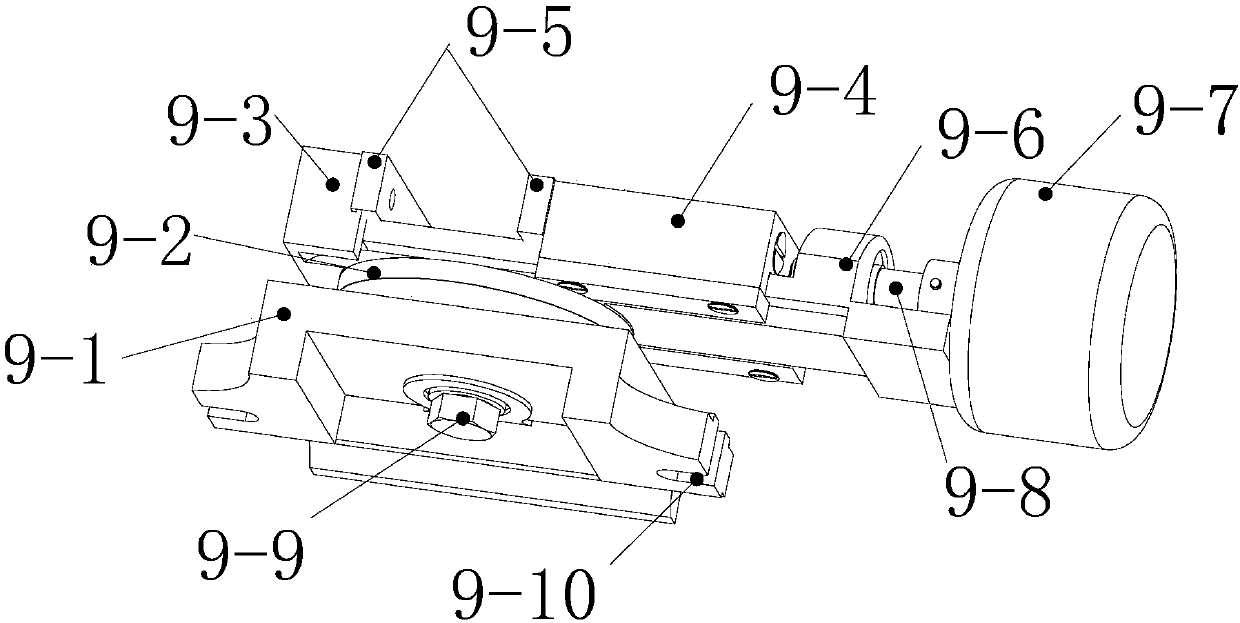

[0016] In the preferred embodiment of the robot assembly line training platform of the present invention, the clamping vise (9) includes a base (9-1), a turntable (9-2), a clamping frame (9-3), a slider ( 9-4), rubber pad (9-5), bearing seat (9-6), rotating shaft (9-8), drive motor (9-7), bolt (9-9); the base (9-1 ) are provided with connecting grooves at both ends, and are fixedly connected to the turntable (7), and a round protrusion is arranged on the top thereof, and the base (9-1) is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com