Electrical connection unit and battery system

A connection unit and electrical connection technology, which is applied in the direction of conductive connection, conductive connection, electrical component connection, etc., can solve the problem of no battery to provide cooling, etc., and achieve the effect of simple and fast installation and simplified manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

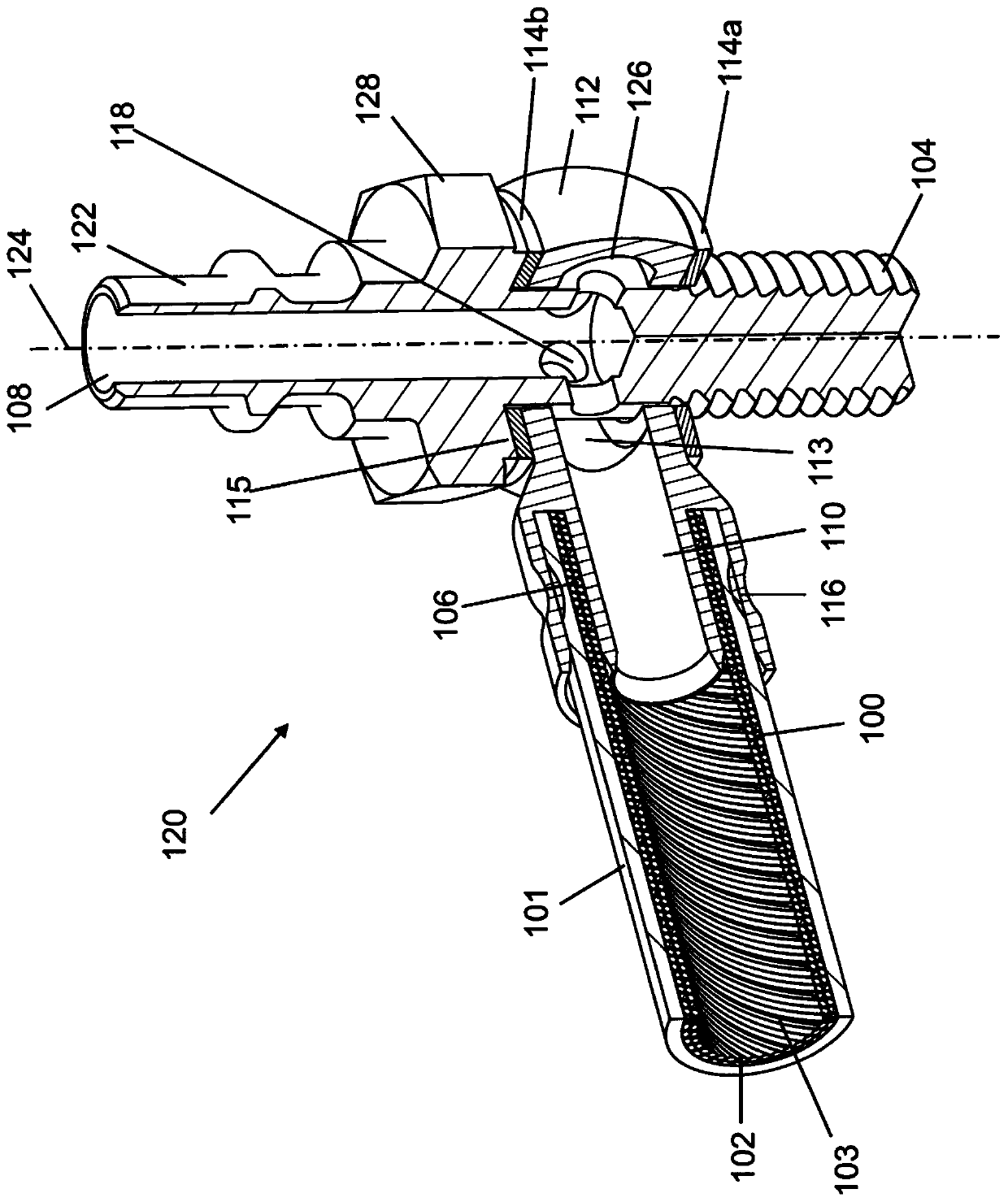

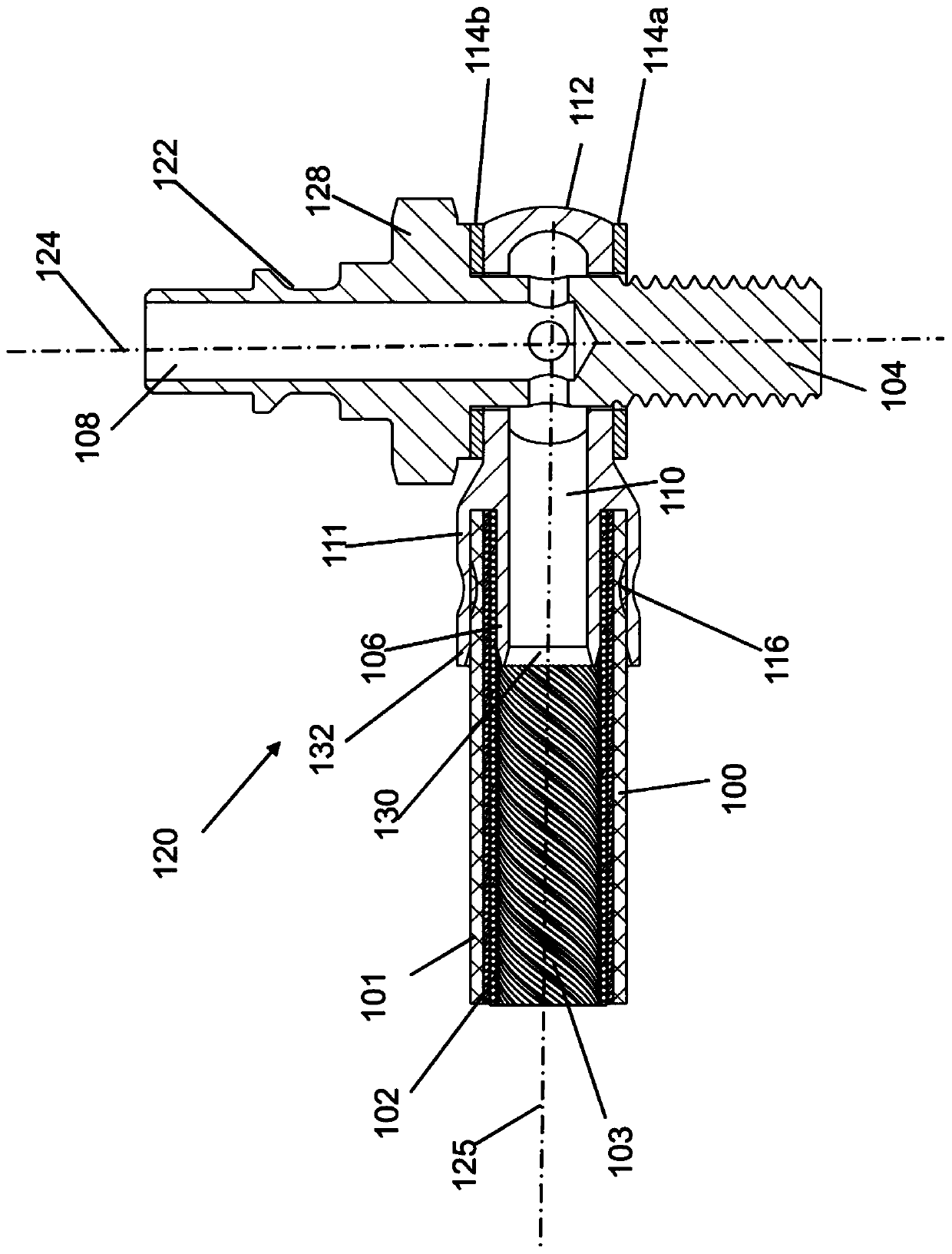

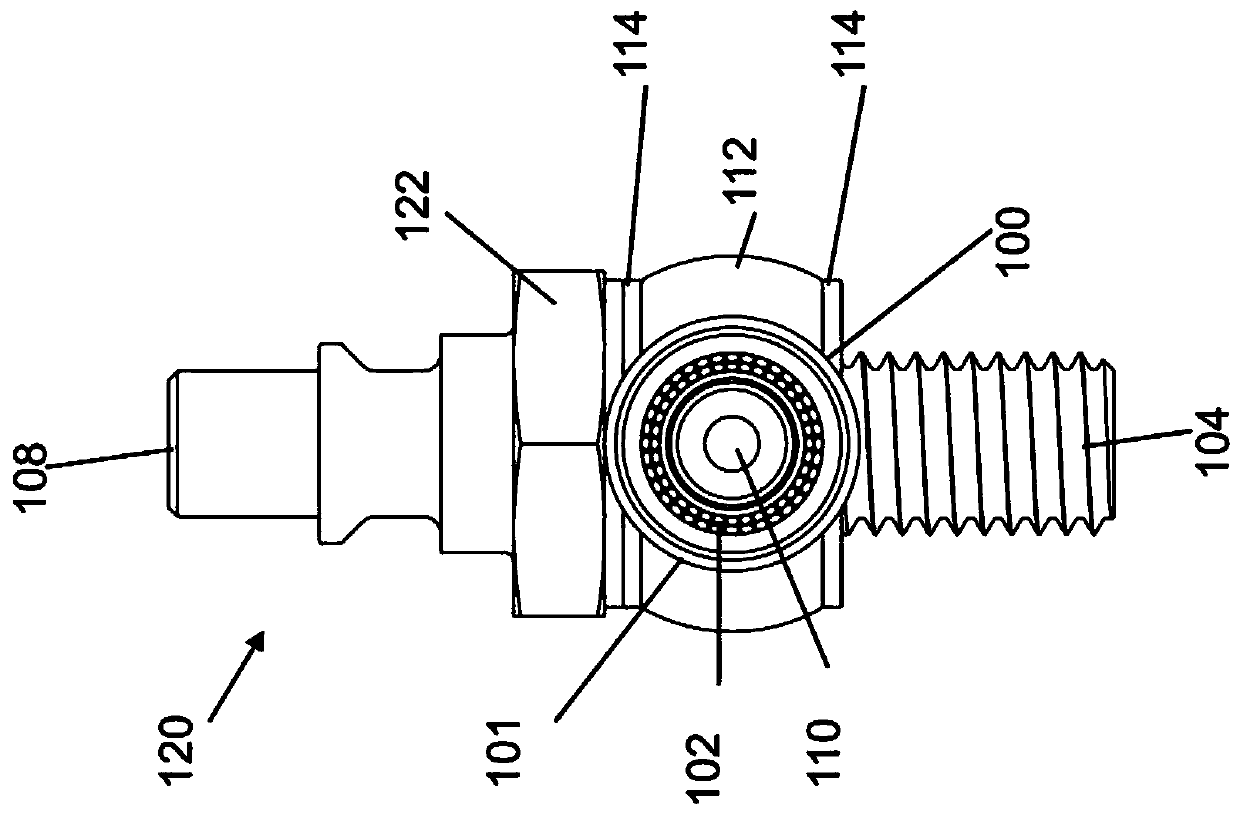

[0035] The invention is explained in more detail below with reference to the accompanying drawings, and first with reference to figure 1 .

[0036] figure 1 An electrical connection unit 120 is shown, which is adapted to electrically contact battery contacts (not shown in the figure). For this purpose, the electrical connection unit 120 has a first electrical terminal 104 which is formed as a screw connection in the illustrated embodiment. However, it is obvious to a person skilled in the art that other configurations of the first electrical terminal can also be used, such as a plug connector or a press-in connection.

[0037] The first electrical terminal 104 is part of a base body 122 that extends along a first longitudinal axis 124 . The base body 122 is partially hollow and has a first fluid terminal 108 for attaching a coolant line (not shown). In the illustrated embodiment, the first fluid terminal 108 is configured as a quick coupling. In this way, the electrical c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap