Wheat straw harvesting and making integrated device for agricultural machinery

A technology of wheat straw and agricultural machinery, which is applied in the field of integrated device for wheat straw harvesting and production for agricultural machinery, which can solve the problems of slow speed, increased production cost, and insufficient transformation, so as to reduce production cost, improve production efficiency, and accelerate decay and the effect of degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

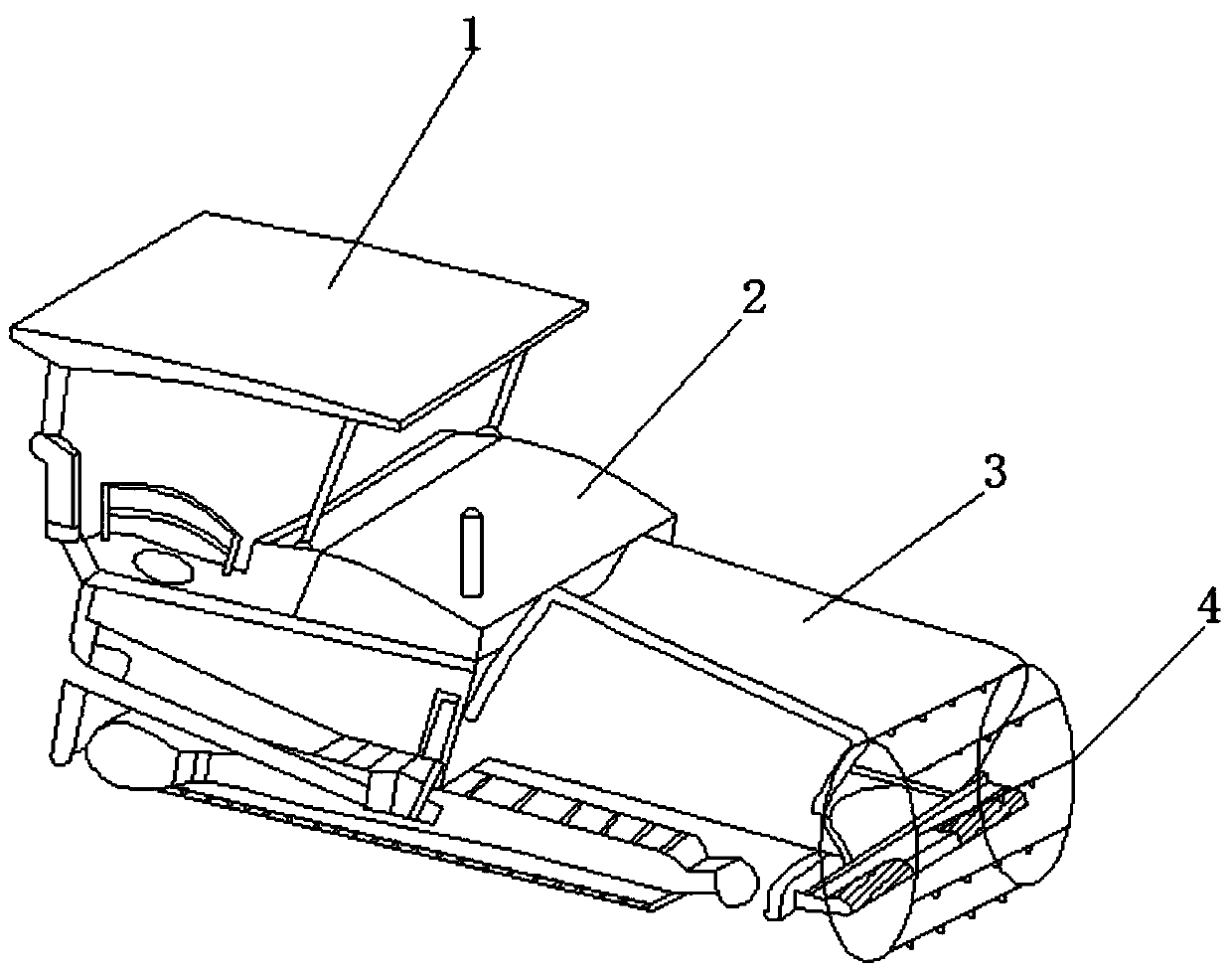

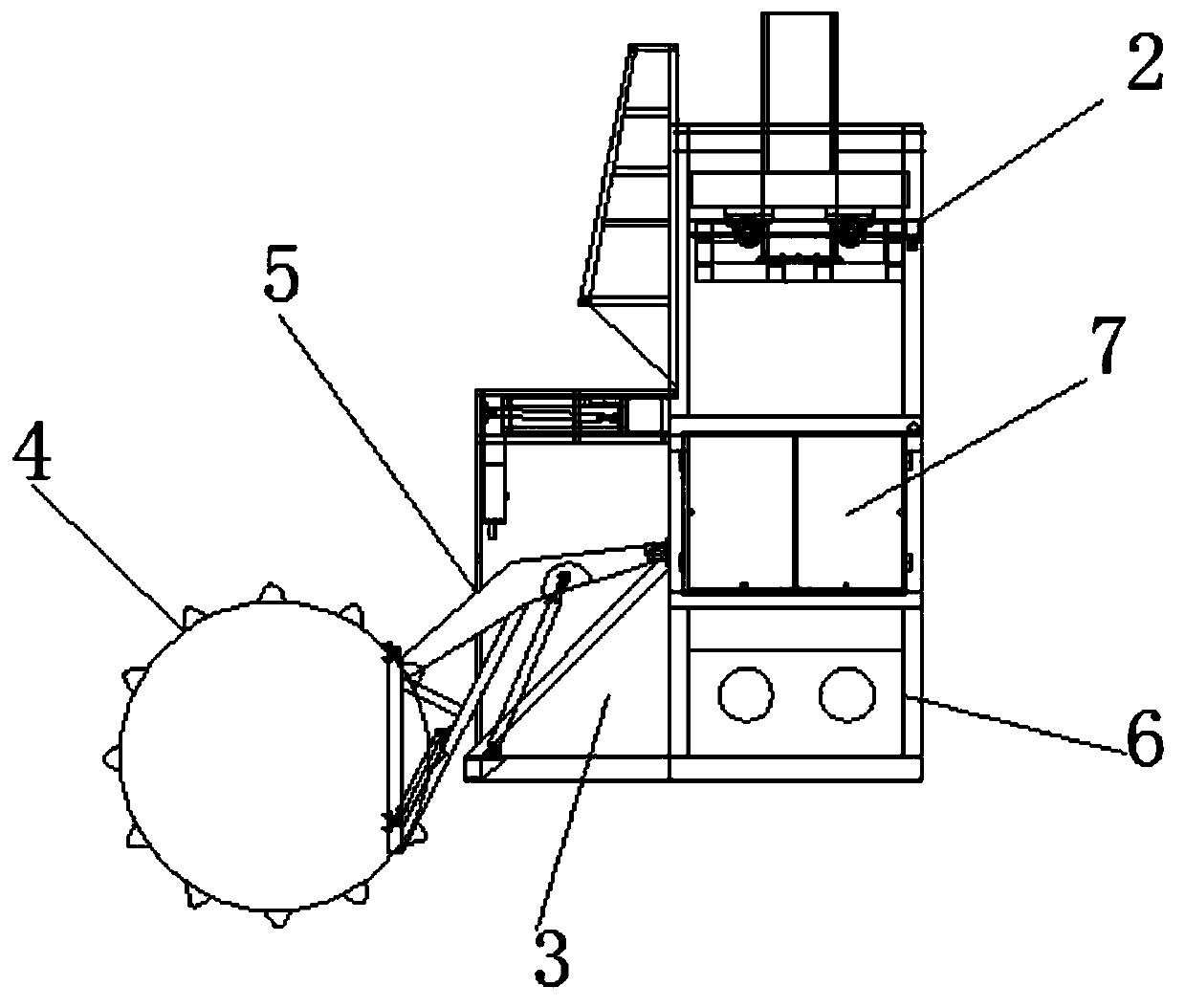

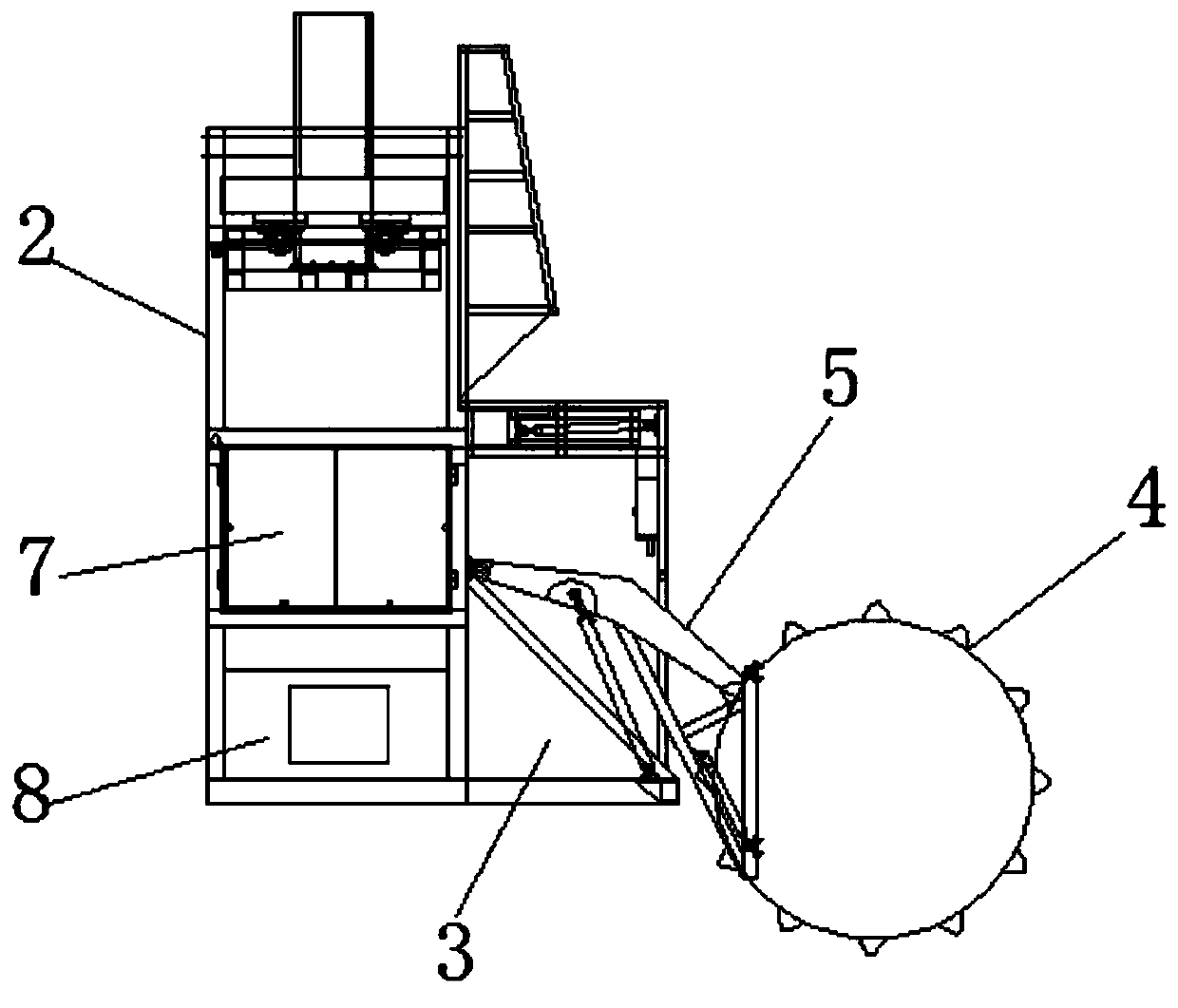

[0033] refer to Figure 1-6, an integrated device for wheat straw harvesting and production for agricultural machinery, comprising a car body control bin, a work box, a conveying channel and a harvesting head, one end of the car body control bin is fixedly connected to a work box, and one side of the work box A conveying channel is fixedly connected, and one end of the conveying channel is connected with a harvesting head through a transmission arm. The working box includes a fertilizer box, a crushing box and a feed box, and a fertilizer box is arranged on one side of the bottom of the crushing box. The other side of the bottom of the crushing box is provided with a feed box, and the car body control bin includes a car body and a controller, and the car body control bin is connected with the first cylinder, the second cylinder, the motor, the blower fan, the compression pump, the first The hydraulic cylinder, the second hydraulic cylinder and the third hydraulic cylinder are ...

Embodiment 2

[0035] refer to Figure 1-6 , an integrated device for wheat straw harvesting and production for agricultural machinery, comprising a car body control bin, a work box, a conveying channel and a harvesting head, one end of the car body control bin is fixedly connected to a work box, and one side of the work box A conveying channel is fixedly connected, and one end of the conveying channel is connected with a harvesting head through a transmission arm. The working box includes a fertilizer box, a crushing box and a feed box, and a fertilizer box is arranged on one side of the bottom of the crushing box. The other side of the bottom of the crushing box is provided with a feed box, and the car body control bin includes a car body and a controller, and the car body control bin is connected with the first cylinder, the second cylinder, the motor, the blower fan, the compression pump, the first The hydraulic cylinder, the second hydraulic cylinder and the third hydraulic cylinder are...

Embodiment 3

[0037] refer to Figure 1-6 , an integrated device for wheat straw harvesting and production for agricultural machinery, comprising a car body control bin, a work box, a conveying channel and a harvesting head, one end of the car body control bin is fixedly connected to a work box, and one side of the work box A conveying channel is fixedly connected, and one end of the conveying channel is connected with a harvesting head through a transmission arm. The working box includes a fertilizer box, a crushing box and a feed box, and a fertilizer box is arranged on one side of the bottom of the crushing box. The other side of the bottom of the crushing box is provided with a feed box, and the car body control bin includes a car body and a controller, and the car body control bin is connected with the first cylinder, the second cylinder, the motor, the blower fan, the compression pump, the first The hydraulic cylinder, the second hydraulic cylinder and the third hydraulic cylinder are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com