An assembly device for an automobile dust cover

An assembly device and dust cover technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increased workload, reduced work efficiency, and hand disease of workers, so as to achieve flexible assembly and improve product quality. The effect of improving quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

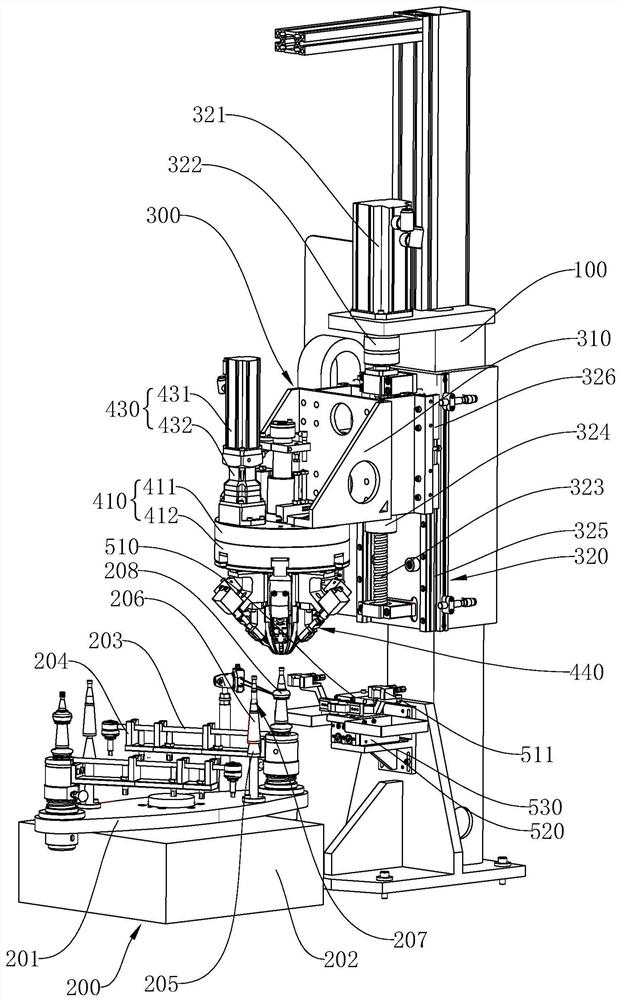

[0040] Embodiment one: if figure 1 As shown, an assembly device for an automobile dust cover includes a frame 100; a rotary table mechanism 200, the rotary table mechanism 200 includes a worktable 201 and a rotary drive motor 202 for driving the rotation of the worktable 201, and the worktable 201 The two ends of the two ends are respectively provided with a limit frame 204 for fixing the product 203 to be installed, and one side of the limit frame 204 is provided with a tapered sleeve limit seat 205, and a tapered sleeve limit seat 205 is placed on the tapered sleeve limit seat 205 for guiding the dust cover 208. The taper sleeve 206, the longitudinal section of the taper sleeve 206 is conical, the taper sleeve 206 is provided with a limiting platform 207, the outer diameter of the limiting platform 207 is about the inner diameter of the upper opening of the dust cover 208, and the limiting platform 207 is used for coarse positioning;

[0041] The vertical press-in mechanism...

Embodiment 2

[0044] Embodiment two: if figure 1 As shown, an assembly device for an automobile dust cover includes a frame 100; a workbench 201, a rotary drive motor 202 is arranged under the workbench 201, and the two ends of the workbench 201 are respectively provided with a limiter for fixing a product 203 to be installed. Position frame 204, one side of limit frame 204 is provided with taper sleeve limit seat 205, is placed on the taper sleeve limit seat 205 and is used for the taper sleeve 206 of dust cover 208 guidance, and the longitudinal section of taper sleeve 206 is conical , the taper sleeve 206 is provided with a limiting platform 207, the outer diameter of the limiting platform 207 is about the inner diameter of the upper opening of the dust cover 208, and the limiting platform 207 is used for rough positioning;

[0045] The vertical press-in mechanism 300, the vertical press-in mechanism 300 includes a mounting frame 310, a vertical conveying mechanism 320 and a jacking mech...

Embodiment 3

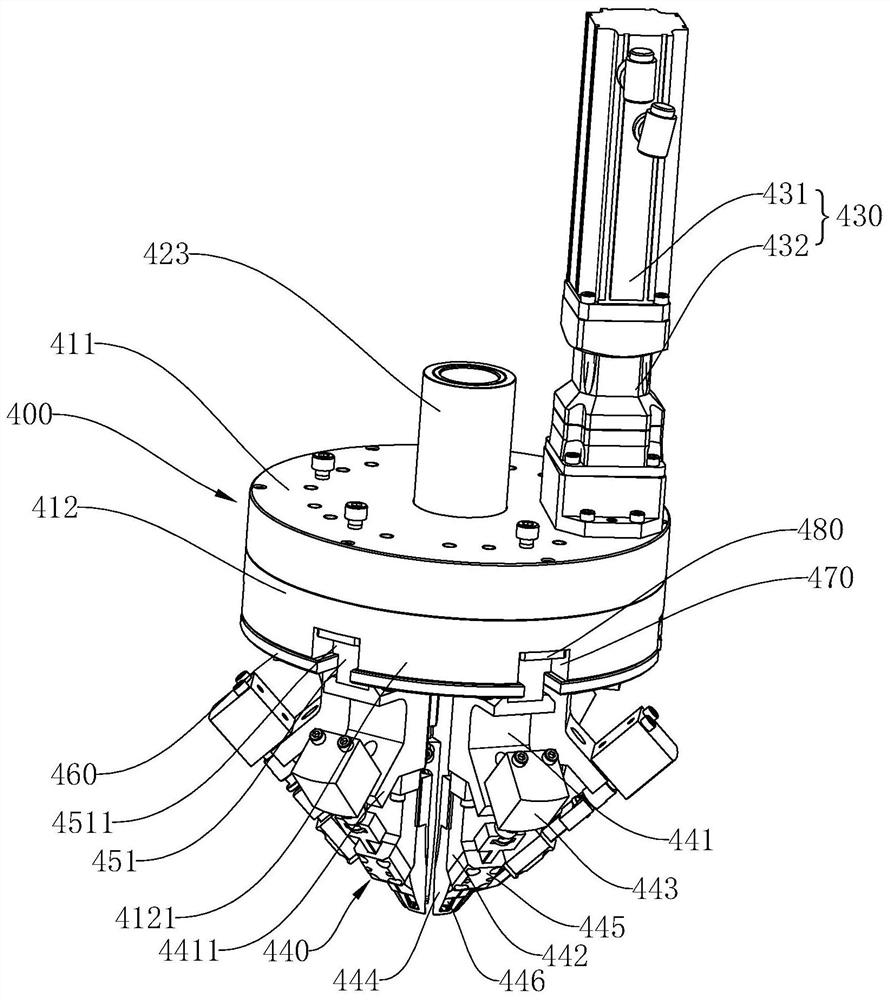

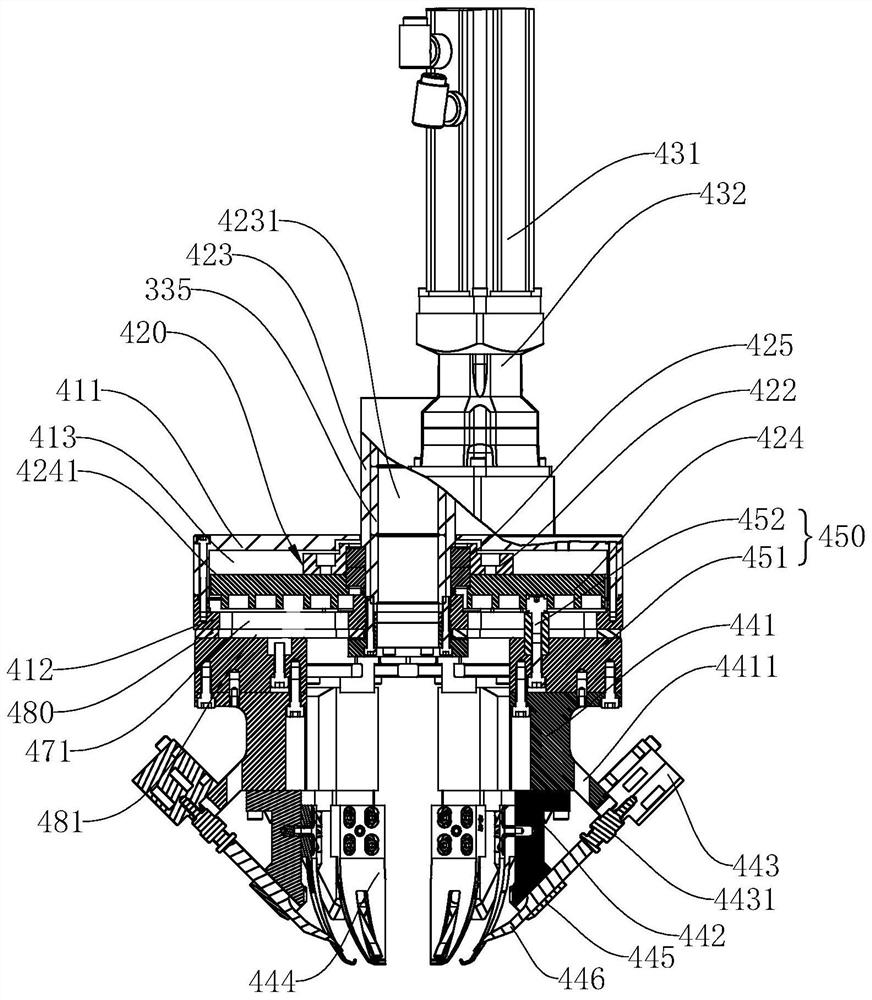

[0053] Embodiment 3: Other structures are the same as Embodiment 2, the difference is that: the middle part of the central shaft 423 is provided with a mounting hole 4231 that penetrates up and down, and the ejector mechanism 330 includes a guide rod sleeve 331, a cover plate 332, and a guide rod 333 , dust cover top barrel 334 and the second drive assembly, the guide rod sleeve 331 is inserted into the installation hole 4231, a guide sleeve 335 is arranged between the central shaft 423 and the guide rod sleeve 331, and the guide rod 333 is vertically penetrated and arranged on the guide rod. In the rod sleeve 331, the cover plate 332 is fixed on the top of the guide rod sleeve 331, the middle part of the guide rod 333 is provided with an outwardly extending limiting plate 336, and the lower end of the guide rod sleeve 331 is provided with an inwardly extending boss 4121, the limit plate 336 is against the boss 4121, a return spring 337 is arranged between the cover plate 332 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com