A double row quenching method

A quenching machine and header technology, applied in the direction of quenching device, furnace, furnace type, etc., to ensure the uniformity of water spray, solve the phenomenon of split ends, and ensure the uniformity of quenching width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

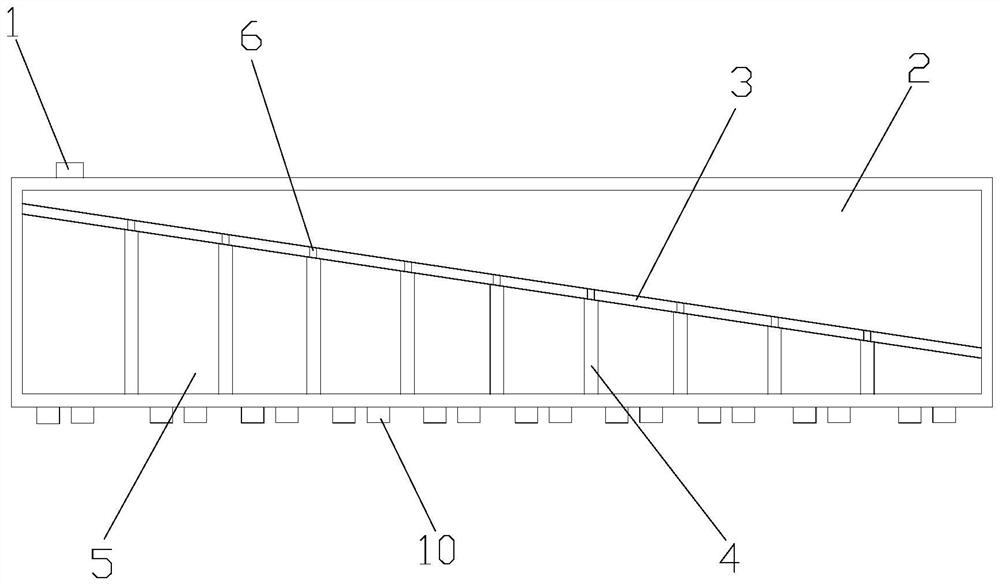

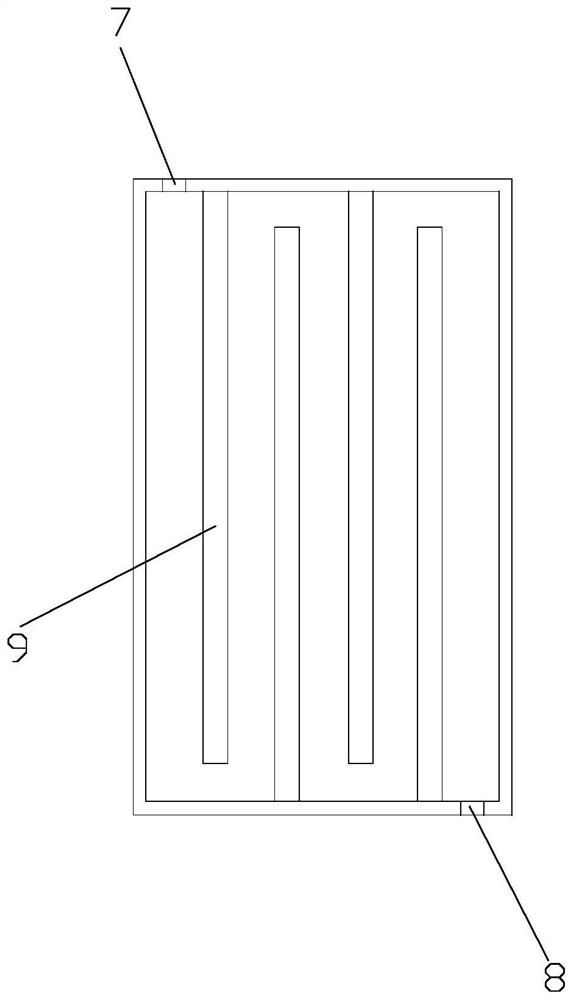

[0031] A double-row quenching method provided in this embodiment has a structure such as Figure 1-2 As shown, the second group of slit nozzles 10 of the quenching machine is changed from the sub-cavity water spray to the through-chamber water spray, the width is set to 4700mm, and the gap opening accuracy in the width direction is 2±0.2mm.

[0032] The header is made of 310S heat-resistant stainless steel, and a damping structure is set in the header to make the water flow evenly swirl and then spray out. One end of the header is provided with a water inlet 1, and the header is provided with a partition plate 3 that divides it into a diversion chamber 2 and a water spray chamber up and down. One end on the same side is higher than the other. The water spray chamber is provided with several damping deflectors 4 evenly distributed along the length direction of the header. The damping deflectors 4 are vertically arranged and hollow inside, and divide the water spray chamber int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com