Extraction system and extraction method of antimony metal

An extraction system and extraction method technology, applied in the field of antimony metal extraction systems, can solve the problems of low extraction rate of antimony metal and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

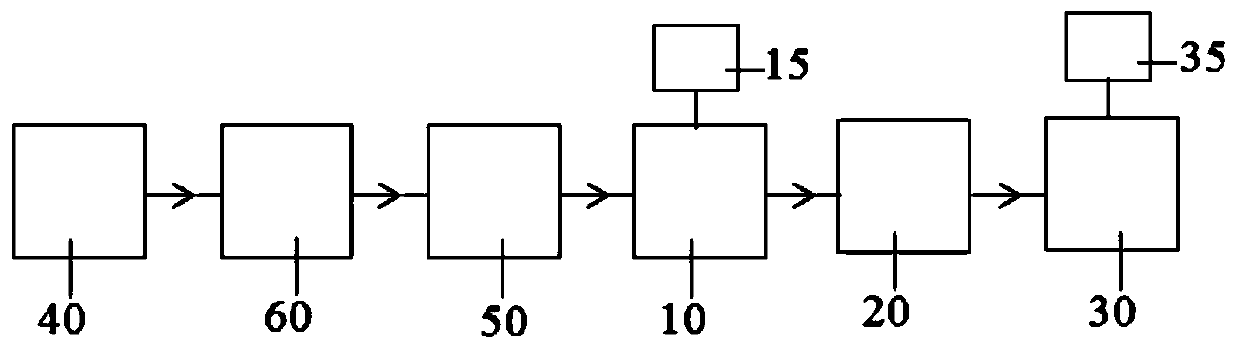

[0073] Such as figure 1 As shown, this process is used for antimony smelting production process, and the antimony smelting production process is divided into two stages: electrothermal volatilization and electrothermal reduction. Both stages use the heating method of electrode arcing to smelt antimony-containing materials.

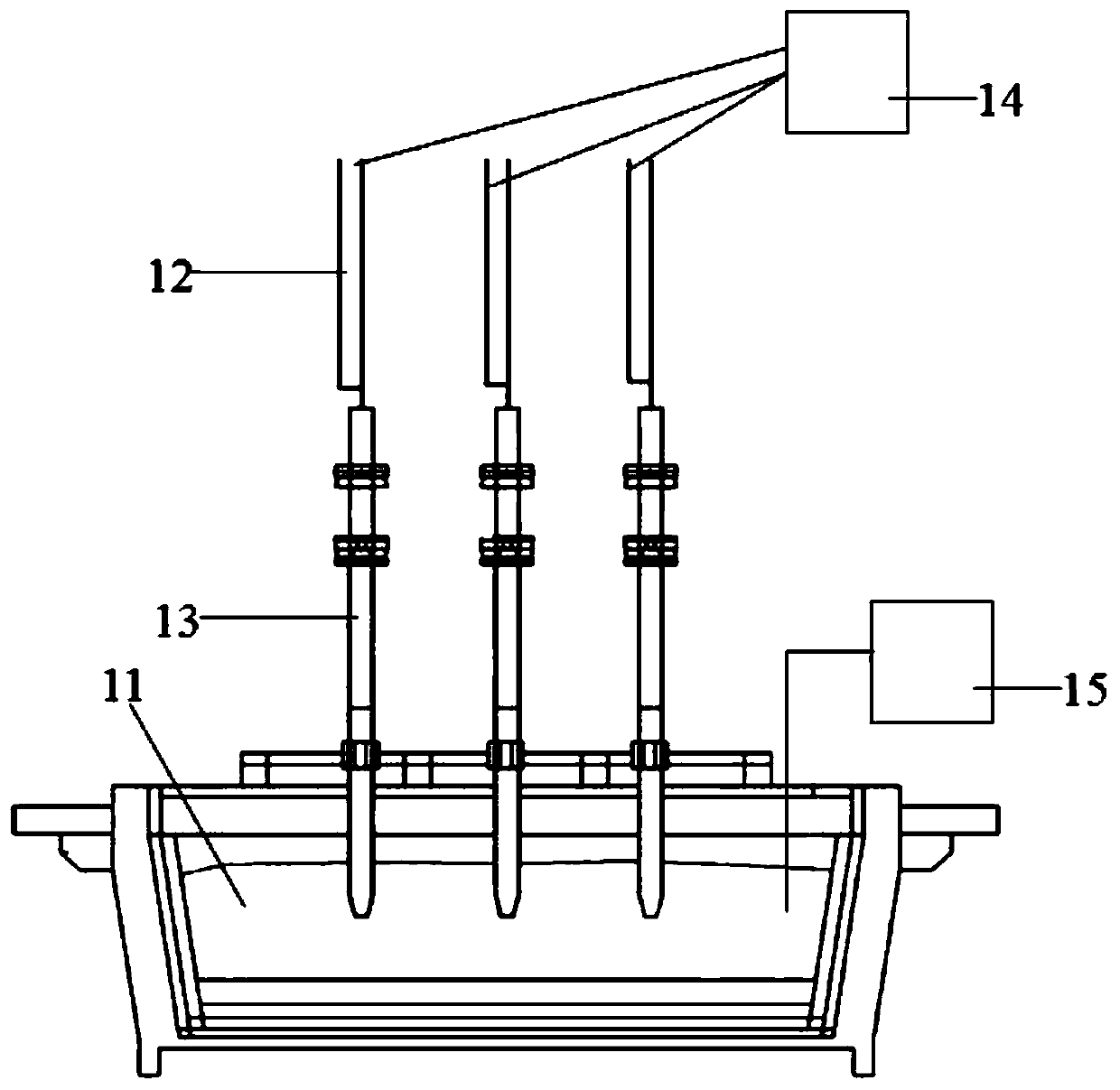

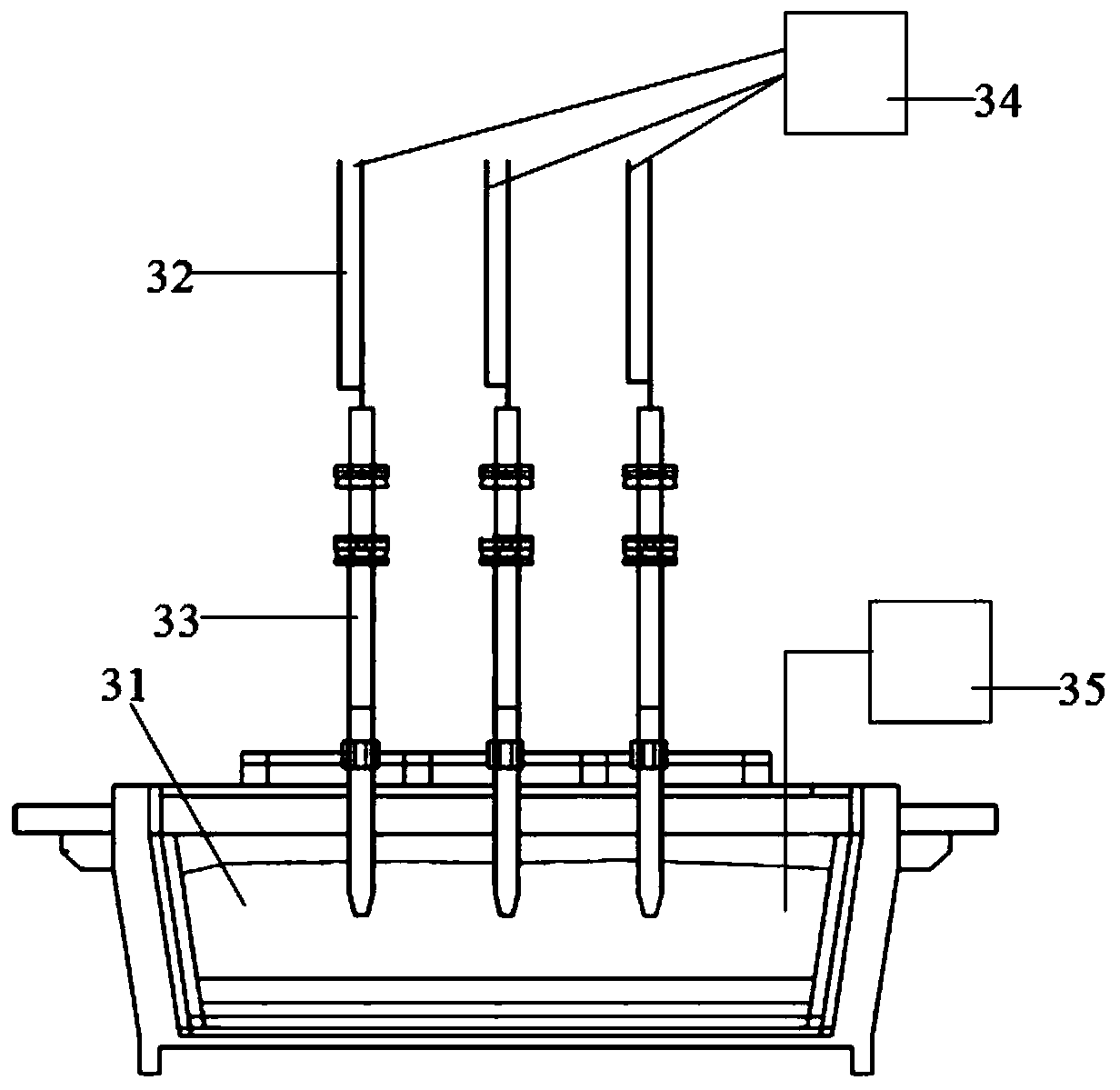

[0074] In the electrothermal volatilization stage, 100kg of dry mineral material and 4kg of coke are first added, and the above raw materials are heated by electrode arc discharge to form a bottom molten pool. Keep the electrode 10cm away from the bottom of the furnace, and start feeding at a constant speed after the current is stable and the furnace temperature is 1200°C. After the electrode is energized, adjust the input power according to the temperature in the furnace to maintain a stable input power, adjust the voltage to 100V, and maintain the current value at 1KA by adjusting the insertion depth to ensure that the furnace temperature rises to 1400°C...

Embodiment 2

[0079] Such as figure 1 As shown, this process is used for antimony smelting production process, and the antimony smelting production process is divided into two stages: electrothermal volatilization and electrothermal reduction. Both stages use the heating method of electrode arcing to smelt antimony-containing materials.

[0080] In the stage of electric heating, 100kg of dry mineral material and 4kg of coke are first added, and the above raw materials are heated by electrode arc discharge to form a bottom molten pool. Keep the electrode 8cm away from the bottom of the furnace, and start feeding at a constant speed after the current is stable and the furnace temperature is 1100°C. After the electrode is energized, the input power is adjusted according to the temperature in the furnace, the voltage is adjusted to 80V, the current value is maintained at 1KA by adjusting the insertion depth, the input power is guaranteed to be 80KW, and the furnace temperature is raised to 1400...

Embodiment 3

[0085] Such as figure 1 As shown, the antimony smelting production process is carried out by using this process, and the antimony smelting production process is divided into two stages: electrothermal volatilization and electrothermal reduction, and the same electrode heating method is used in both stages.

[0086] In the stage of electric heating, 100kg of dry mineral material and 4kg of coke are first added, and the above raw materials are heated by electrode arc discharge to form a bottom molten pool. Keep the electrode 100mm away from the bottom of the furnace, and start feeding at a constant speed after the current is stable and the furnace temperature is 1200°C. After the electrode is energized, the input power is adjusted according to the temperature in the furnace, the voltage is adjusted to 100V, the current value is maintained at 1KA by adjusting the insertion depth, and the input power is 100KW to ensure that the furnace temperature rises to 1400°C within half an ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com