Iron-based amorphous/carbon nanotube composite material for low-loss and high-corrosion-resistance transformer iron core and preparing method and application of iron-based amorphous/carbon nanotube composite material

A transformer core, iron-based amorphous technology, which is applied in inductance/transformer/magnet manufacturing, magnetic materials, electrical components, etc., can solve the problems of poor dispersion, reduced performance of transformer cores, and small size of carbon nanotubes. The effect of improving plastic toughness, good amorphous forming ability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

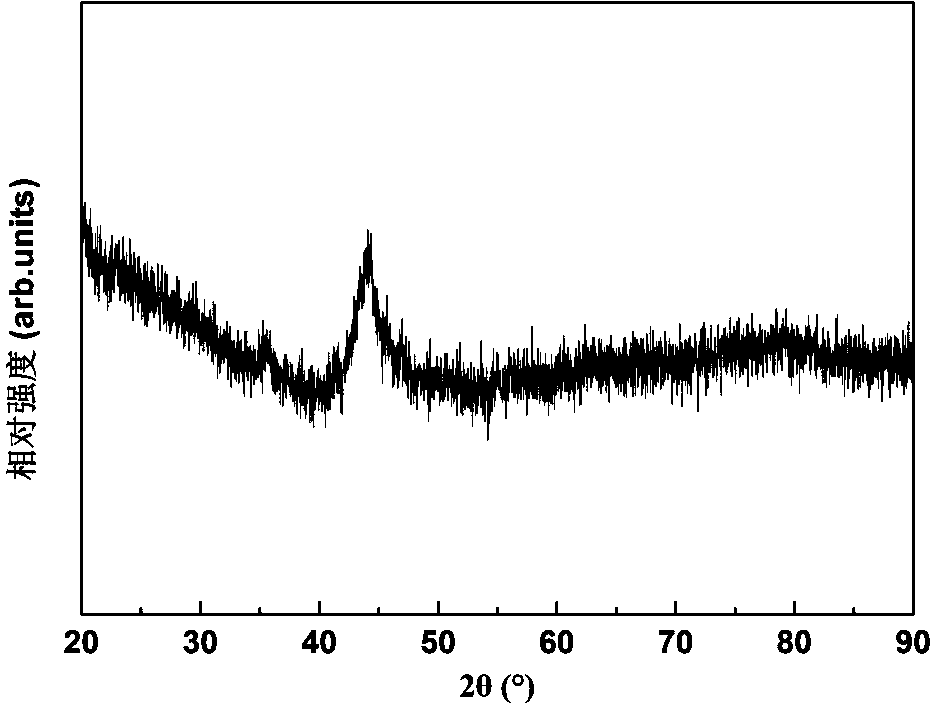

Image

Examples

Embodiment 1

[0027] An iron-based amorphous / carbon nanotube composite material for a low-loss and high-corrosion-resistant transformer core, including iron-based amorphous and carbon nanotubes, wherein the content of carbon nanotubes is 0.5 wt%; the iron-based amorphous includes the following Composition in weight percent: 28wt% Cr, 3wt% B, 6wt% Si, 4wt% P, 5wt% Ni, 8wt% Mo, 3wt% Nb, the balance being Fe; the carbon nanotubes are prepared by chemical vapor deposition into, its purity is not less than 90%.

[0028] Wherein, the iron-based amorphous / carbon nanotube composite tape is prepared by the following steps:

[0029] (1) According to the above-mentioned iron-based amorphous composition and weight ratio, weigh low-carbon ferrochrome, ferroboron, ferrosilicon, ferrophosphorus, electrolytic nickel, ferromolybdenum, ferroniobium and pure iron. The principle of adding the materials containing elements that are easy to burn at the end is to put ferromolybdenum, low-carbon ferrochrome, pure...

Embodiment 2

[0039] An iron-based amorphous / carbon nanotube composite material for a low-loss and high-corrosion-resistant transformer core, including iron-based amorphous and carbon nanotubes, wherein the content of carbon nanotubes is 1 wt%; the iron-based amorphous includes the following Composition in weight percent: 28wt% Cr, 3wt% B, 6wt% Si, 4wt% P, 5wt% Ni, 8wt% Mo, 3wt% Nb, the balance being Fe; the carbon nanotubes are prepared by chemical vapor deposition become.

[0040] The preparation method of the iron-based amorphous, the application and construction method of the amorphous / carbon nanotube composite material in the iron core in this embodiment are all the same as those in Embodiment 1.

Embodiment 3

[0042] An iron-based amorphous / carbon nanotube composite material for a low-loss and high-corrosion-resistant transformer core, including iron-based amorphous and carbon nanotubes, wherein the content of carbon nanotubes is 1.5 wt%; the iron-based amorphous includes the following Composition in weight percent: 28wt% Cr, 3wt% B, 6wt% Si, 4wt% P, 5wt% Ni, 8wt% Mo, 3wt% Nb, the balance being Fe; the carbon nanotubes are prepared by chemical vapor deposition become.

[0043] The preparation method of the iron-based amorphous, the application and construction method of the amorphous / carbon nanotube composite material in the iron core in this embodiment are all the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com