Edge chamfering structure of honeycomb ceramic particle catcher

A technology of particle traps and honeycomb ceramics, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., to achieve enhanced thermal shock resistance, simple and easy design, and small back pressure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

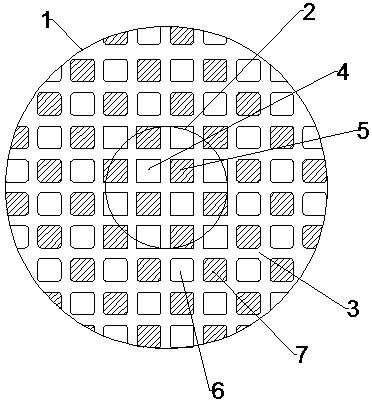

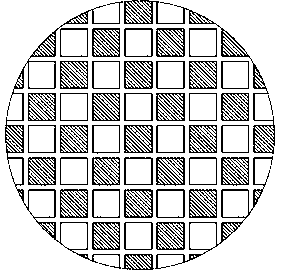

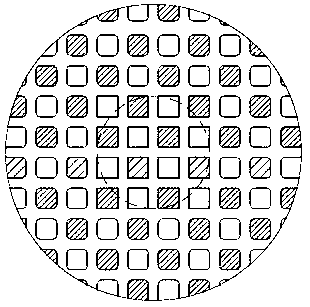

[0028] Such as Figure 1-6 As shown, the edge chamfering structure of the honeycomb ceramic particle catcher according to the embodiment of the present invention includes a honeycomb ceramic particle catcher body 1, and the honeycomb ceramic particle catcher body 1 is composed of a central area 2 and an edge area 3, so The central area 2 is located in the middle of the honeycomb ceramic particle trap body 1, the edge area 3 is located inside the honeycomb ceramic particle trap body 1 and outside the central area 2, and the central area A number of channel holes 1 4 and a number of channel holes 2 5 are arranged inside the 2, and a number of channel holes 3 6 and a number of channel holes 4 7 are arranged inside the edge area 3 .

[0029] Let's talk about the specific settings and effects of channel hole one 4, channel hole two 5, channel hole three 6 and channel hole four 7 below.

[0030] Such as figure 1 As shown, channel hole 3 6 and channel hole 4 7 are respectively subj...

Embodiment 2

[0033] Such as Figure 1-6 As shown, the ratio of the diameter of the central area 2 to the diameter of the honeycomb ceramic particle trap body 1 is between 0-0.5, the first channel hole 4, the second channel hole 5, and the third channel hole 6 The cross-sections of the channel holes 4 and 7 are square structures respectively, the channel hole 1 4 and the channel hole 2 5 are non-chamfered structures, the channel hole 3 6 is a chamfered structure, and the channel The chamfering structure of hole three 6 is one of arc chamfering and straight chamfering, the channel hole four 7 is a chamfering structure, and the chamfering structure of the channel hole four 7 is arc chamfering and one of straight chamfers.

[0034] The ratio of the diameter of the central area 2 to the diameter of the honeycomb ceramic particle trap body 1 is between 0-0.5, and the optimum range of the diameter ratio of the central area 2 to the diameter of the honeycomb ceramic particle trap body 1 is 0.1 B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com