Corn cross pollination device

A hybrid pollination and corn technology, which is applied in plant genetic improvement, botanical equipment and methods, applications, etc., can solve the problems of high time and economic costs, troublesome pollination, and high labor intensity of operation, so as to improve pollination efficiency and reduce labor intensity , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

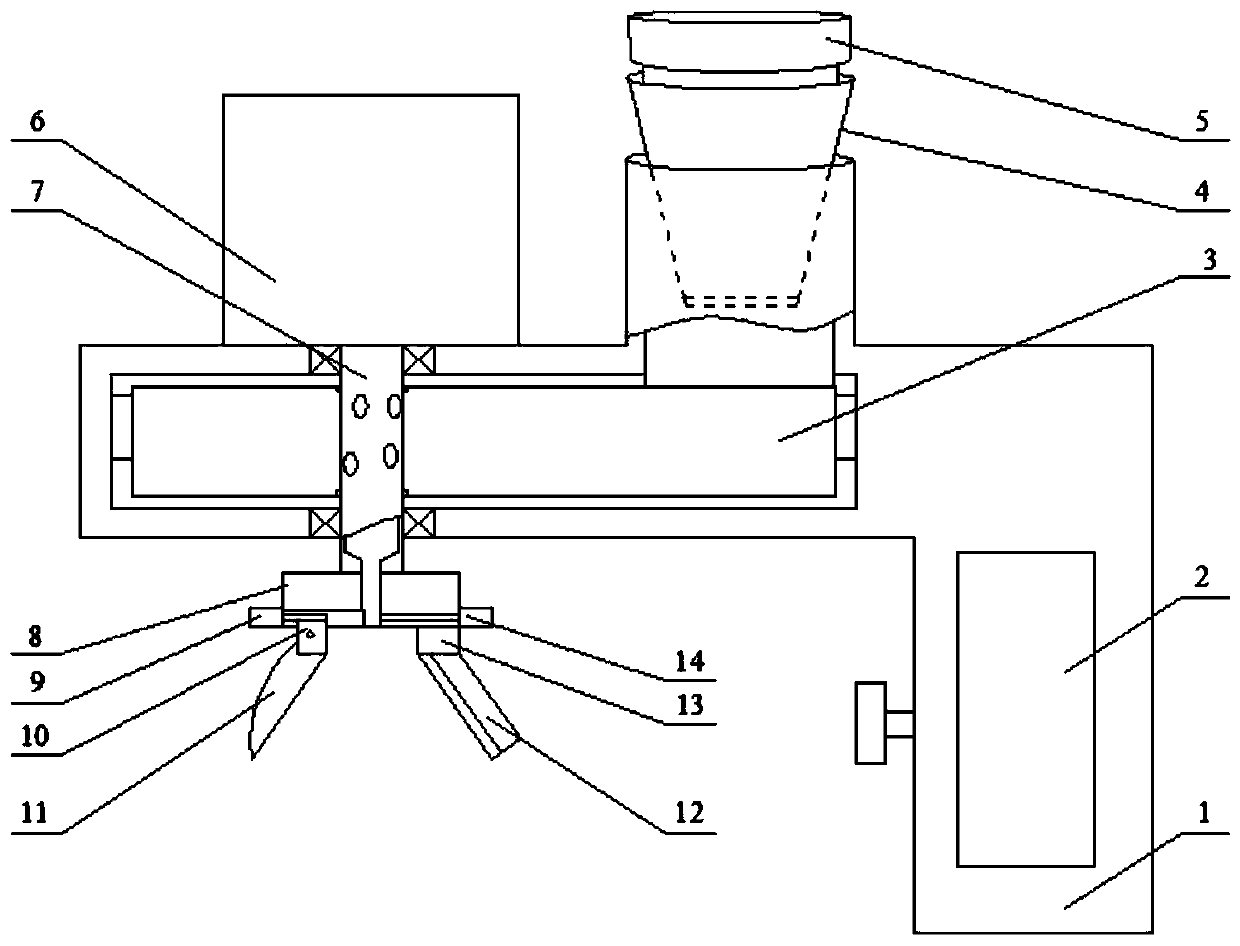

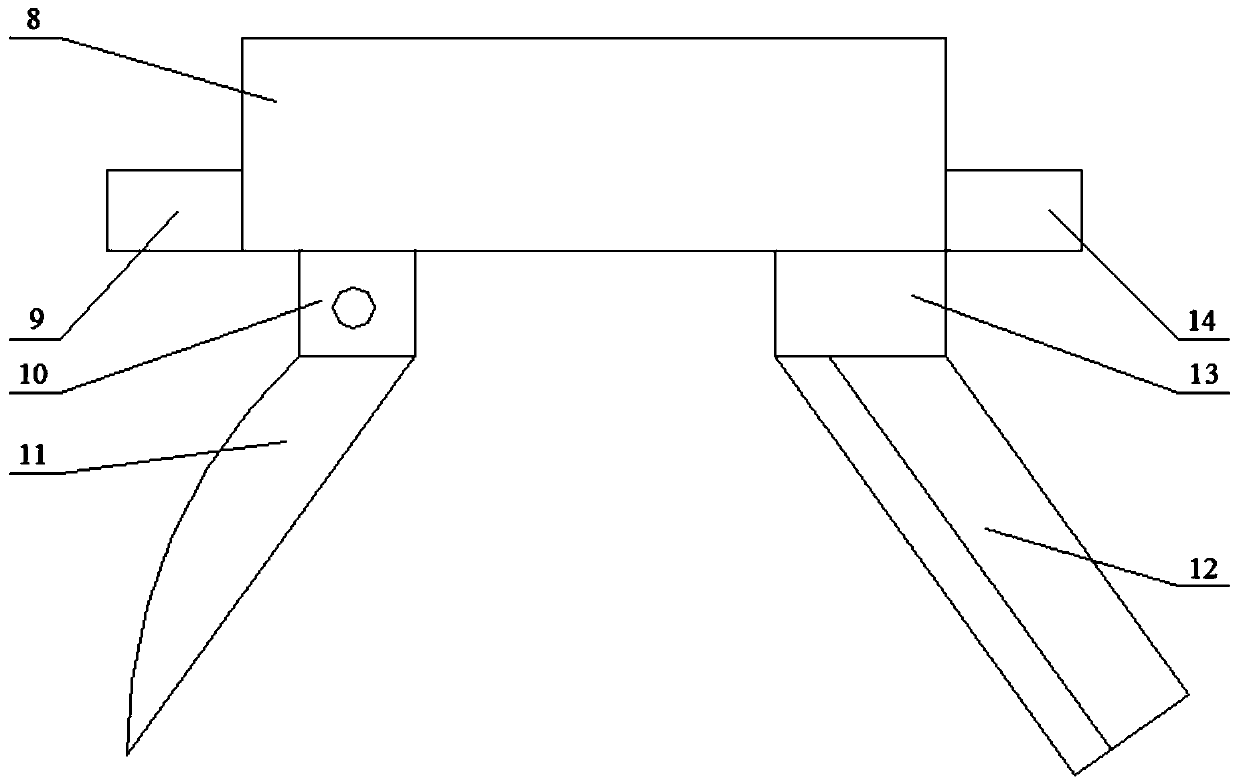

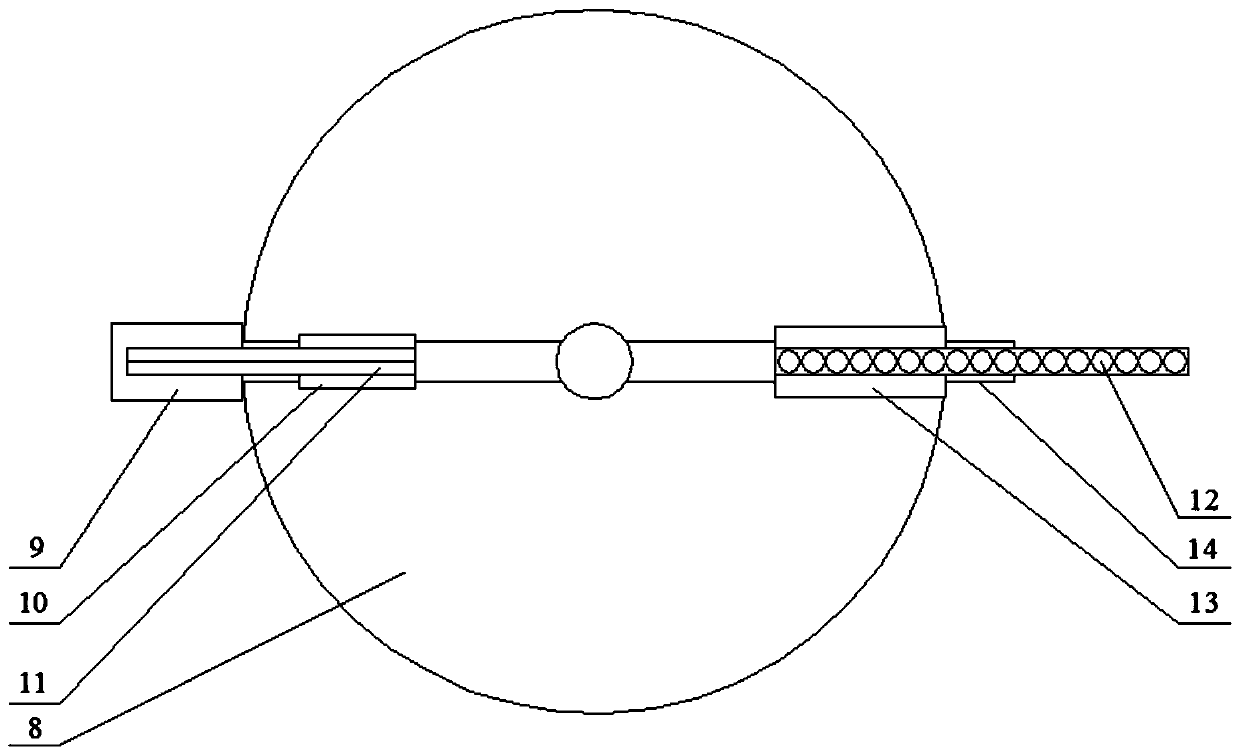

[0019] Such as figure 1 , figure 2 and image 3 As shown, a kind of corn hybrid pollinator provided by the present invention includes a housing 1 used as a support, and a housing 3 for containing pollen is erected in the housing 1, and the housing 3 is fixed with the housing 1. Inside the housing 3 A rotating shaft 7 is pierced, and the contact surface between the rotating shaft 7 and the casing 3 is dynamically sealed. One end of the rotating shaft 7 passes through the casing 3 and the casing 1 and is connected to the output shaft of the motor 6. The motor 6 is fixed to the casing 1, and the rotating shaft 7 After the other end passes through the box body 3 and the housing 1, an installation block-8 is fixedly connected to the end thereof, and the side of the installation block-8 away from the rotating shaft 7 is provided with a device for trimming the bract leaves of the ear of corn so as to expose the filaments. The blade portion 11.

[0020] Wherein, the blade portion ...

Embodiment 2

[0028] As a further improvement on the basis of Embodiment 1, this embodiment adds a structure for homogenizing the pollen to prevent excessive accumulation of pollen in one place.

[0029] Specifically, the installation block three 13 is provided on the installation block one 8, the installation block three 13 is located on the opposite side of the blade portion 11, the installation block three 13 is fixed with the installation block one 8, and the installation block three 13 is provided with a The brush body 12 that evenly disperses the pollen on the filaments, the brush body 12 is arranged obliquely, and the angle with the surface of the mounting block 18 is 20° to 35°, and the inside of the brush body 12 is provided with a plurality of through holes for pollen passages 3, The third through hole communicates with the first through hole below the butterfly valve.

[0030] In use, after the corn husk is cut, the butterfly valve can be activated to open the pollen circulation ...

Embodiment 3

[0032] As a further improvement on the basis of Embodiment 2, this embodiment adds a structure for adjusting the radius of rotation of the blade, so as to adapt to corns of different sizes and increase the adaptability of the device.

[0033] Specifically, a position adjustment device is provided on the first installation block 8, and the second installation block 10 is fixed on the moving body of the position adjustment device, and the second installation block 10 is detachably connected with the blade portion 11.

[0034] Wherein, the position adjustment device includes an electric push rod 9, and the electric push rod 9 is fixed to the side wall of the installation block one 8, and the push rod of the electric push rod 9 is arranged in the installation groove provided on the surface of the installation block one 8, so The end of the telescopic rod of the electric push rod 9 is fixed with the second installation block 10, and the second installation block 10 is slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com