Oil and fat composition

A technology for oil composition and fish oil, which is applied in the directions of edible oil/fat, food science, application, etc., and can solve the problems of single nutrient composition and unfavorable nutritional balance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

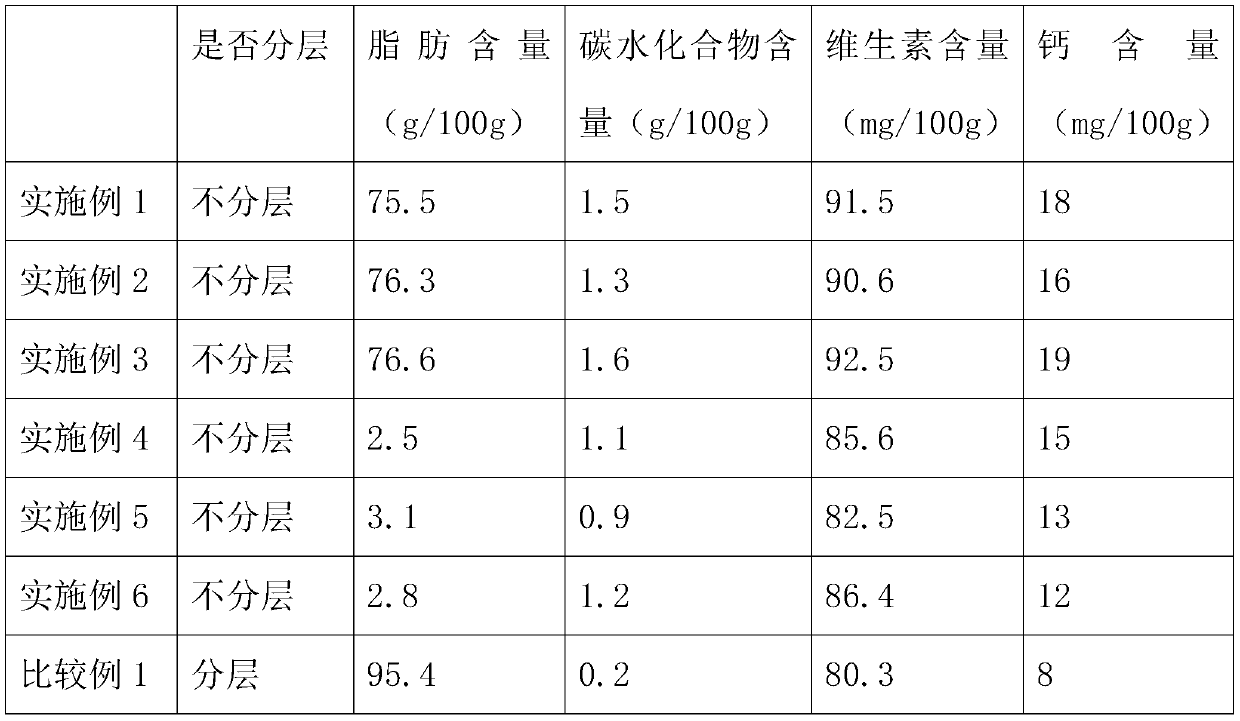

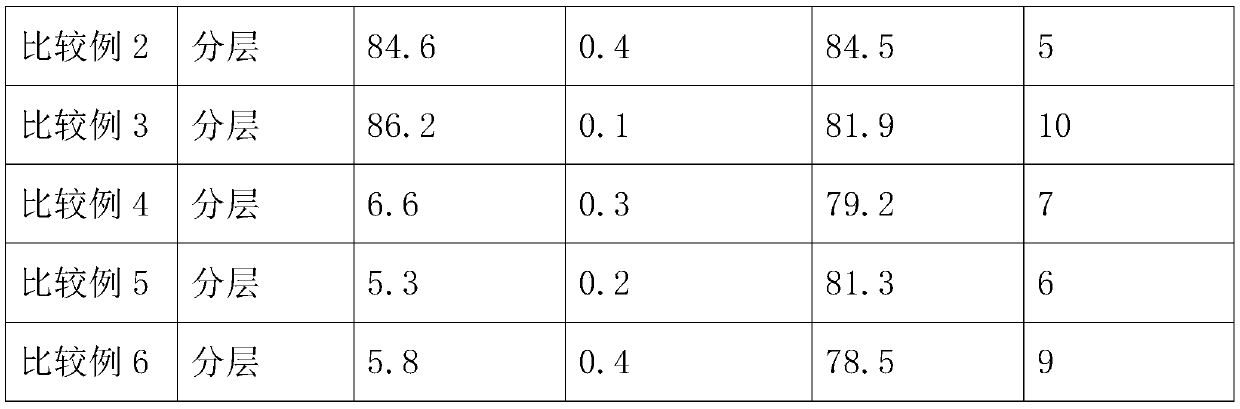

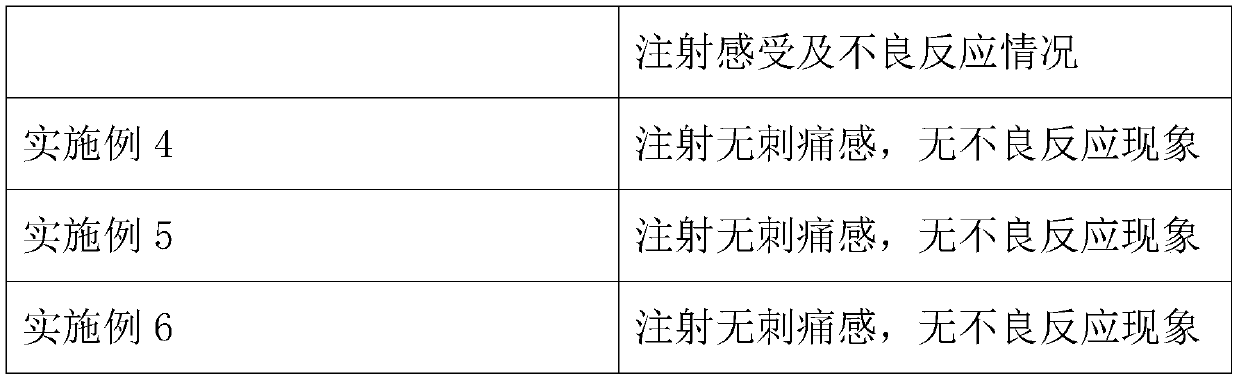

Examples

Embodiment 1

[0055] A grease composition, comprising the following components in parts by mass:

[0056] 30kg of soybean oil; 40kg of olive oil; 17.5kg of fish oil; 4kg of lecithin; 3kg of sucrose palmitate; 7kg of edible alcohol.

[0057] The preparation method of oil composition is as follows:

[0058] S1. Add 30kg of soybean oil, 40kg of olive oil, 17.5kg of fish oil, 4kg of lecithin, 3kg of sucrose palmitate, and 7kg of edible alcohol into the first closed reactor, control the temperature at 35°C, and stir at a speed of 250r / min , and at the same time, adopt 320Hz ultrasonic vibration for 5min to form a premix.

[0059] S2. Stir at a speed of 300 r / min, add 1 kg of protease to the premix while stirring, and control the temperature to 45°C. Then transfer the premix to a washing tank, stir and heat to 45°C to keep warm, and while stirring, add sodium hydroxide solution with a mass concentration of 10% to adjust the pH to 8, react for 30 minutes while stirring, and then evenly spray 10m...

Embodiment 2

[0064] A grease composition, comprising the following components in parts by mass:

[0065] 35kg of soybean oil; 35kg of olive oil; 20kg of fish oil; 5kg of lecithin; 1kg of sucrose palmitate; 6kg of edible alcohol.

[0066] The preparation method of oil composition is as follows:

[0067] S1. Add 35kg of soybean oil, 35kg of olive oil, 20kg of fish oil, 5kg of lecithin, 1kg of sucrose palmitate, and 6kg of edible alcohol into the first closed reactor, control the temperature at 38°C, and stir at a speed of 250r / min. At the same time, 330 Hz ultrasonic vibration was used for 4 minutes to form a premix.

[0068] S2. Stir at a speed of 300 r / min, add 1.3 kg of protease to the premix while stirring, and control the temperature to 50°C. Then transfer the premix to a washing tank, stir and heat to 50°C to keep warm, and while stirring, add a sodium hydroxide solution with a mass concentration of 10% to adjust the pH to 8.5, react for 30 minutes while stirring, and then evenly spr...

Embodiment 3

[0073] A grease composition, comprising the following components in parts by mass:

[0074] 40kg of soybean oil; 37.5kg of olive oil; 15kg of fish oil; 3kg of lecithin; 2kg of sucrose palmitate; 5kg of edible alcohol.

[0075] The preparation method of oil composition is as follows:

[0076] S1. Add 40kg of soybean oil, 37.5kg of olive oil, 15kg of fish oil, 3kg of lecithin, 2kg of sucrose palmitate, and 5kg of edible alcohol into the first closed reactor, control the temperature at 40°C, and stir at a speed of 250r / min , at the same time, adopt 340Hz ultrasonic vibration for 3min to form a premix.

[0077] S2. Stir at a speed of 300 r / min, add 1.5 kg of protease to the premix while stirring, and control the temperature to 55°C. Then transfer the premix to a washing tank, stir and heat to 55°C and keep it warm, and add a sodium hydroxide solution with a mass concentration of 10% while stirring to adjust the pH to 9, react for 30 minutes while stirring, and then evenly spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com