A kind of supported molybdenum series catalyst, its preparation method and application

A catalyst and supported technology, which is applied in the field of its preparation and supported molybdenum-based catalysts, can solve the problems that the reaction cannot be guaranteed, the preparation method is complicated, and the free hydroxyl group cannot be used, so as to achieve good dissolution effect, increase the number of active sites, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

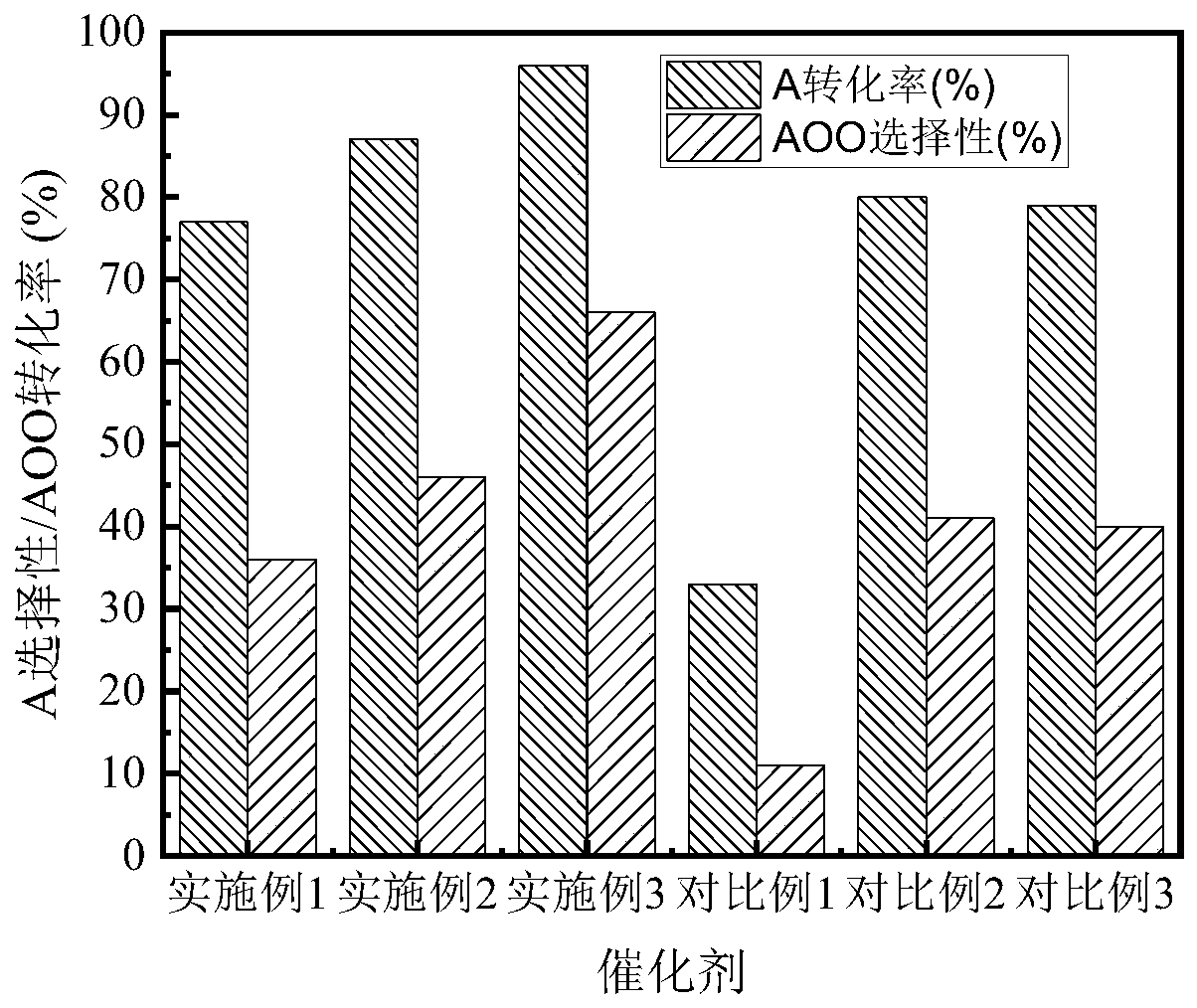

Embodiment 1

[0039] Take 0.5g MoO 3 Place in a stainless steel reaction kettle lined with polytetrafluoroethylene, add 10mL, 6mol / L HCl aqueous solution, seal it, and react at 150°C for 2h.

[0040] Add 5.0g SiO to the above reaction kettle 2 Small balls, sealed, reacted at 150°C for 12h, washed, filtered to obtain MoOCl / SiO 2 catalyst.

[0041] to MoOCl / SiO 2 Add 20mL, 46wt.% tert-butyl hydroperoxide solution in tert-butanol to the catalyst, stir at 25°C for 12h, filter, and vacuum-dry at 40°C for 12h to obtain MoO 4 2- / SiO 2 catalyst.

Embodiment 2

[0043] Take 1.0g MoO 3 Place in a stainless steel reaction kettle lined with polytetrafluoroethylene, add 10mL, 6mol / L HCl aqueous solution, seal it, and react at 150°C for 2h.

[0044] Add 5.0g SiO to the above reaction kettle 2 Small balls, sealed, reacted at 150°C for 12h, washed, filtered to obtain MoOCl / SiO 2 catalyst.

[0045] to MoOCl / SiO 2 Add 20mL, 46wt.% tert-butyl hydroperoxide solution in tert-butanol to the catalyst, stir at 25°C for 12h, filter, and vacuum-dry at 40°C for 12h to obtain MoO 4 2- / SiO 2 catalyst.

Embodiment 3

[0047] Take 1.0g MoO 3 Place in a stainless steel reaction kettle lined with polytetrafluoroethylene, add 10mL, 6mol / L HCl aqueous solution, seal, react at 150°C for 12h, and filter.

[0048] The above filtrate was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and 5.55 g of 10 wt% MoO was added 3 SiO 2 Small balls, sealed, reacted at 150°C for 12h, washed, filtered to obtain MoOCl / SiO 2 catalyst.

[0049] To the MoOCl / SiO 2 Add 20mL, 46wt% tert-butyl hydroperoxide solution in tert-butanol to the catalyst, stir at 25°C for 12h, filter, and vacuum-dry at 40°C for 12h to obtain MoO 4 2- / SiO 2 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com