Soil beating mechanism and soil remediation system

A soil and beating bucket technology, applied in the field of soil remediation, can solve the problems of stirring blade damage, processing chain extension costs, etc., and achieve the effect of promoting dissolution and facilitating centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

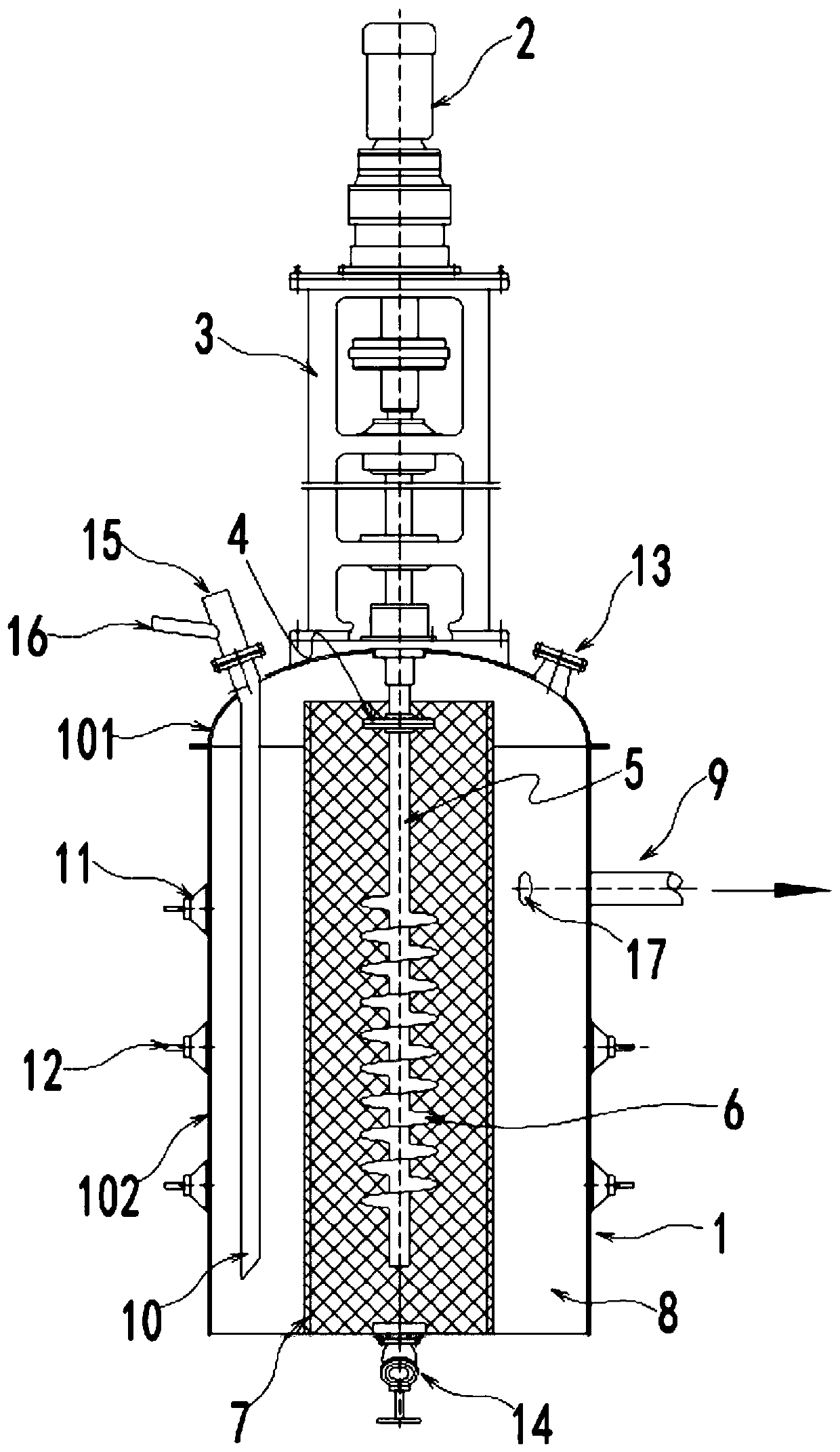

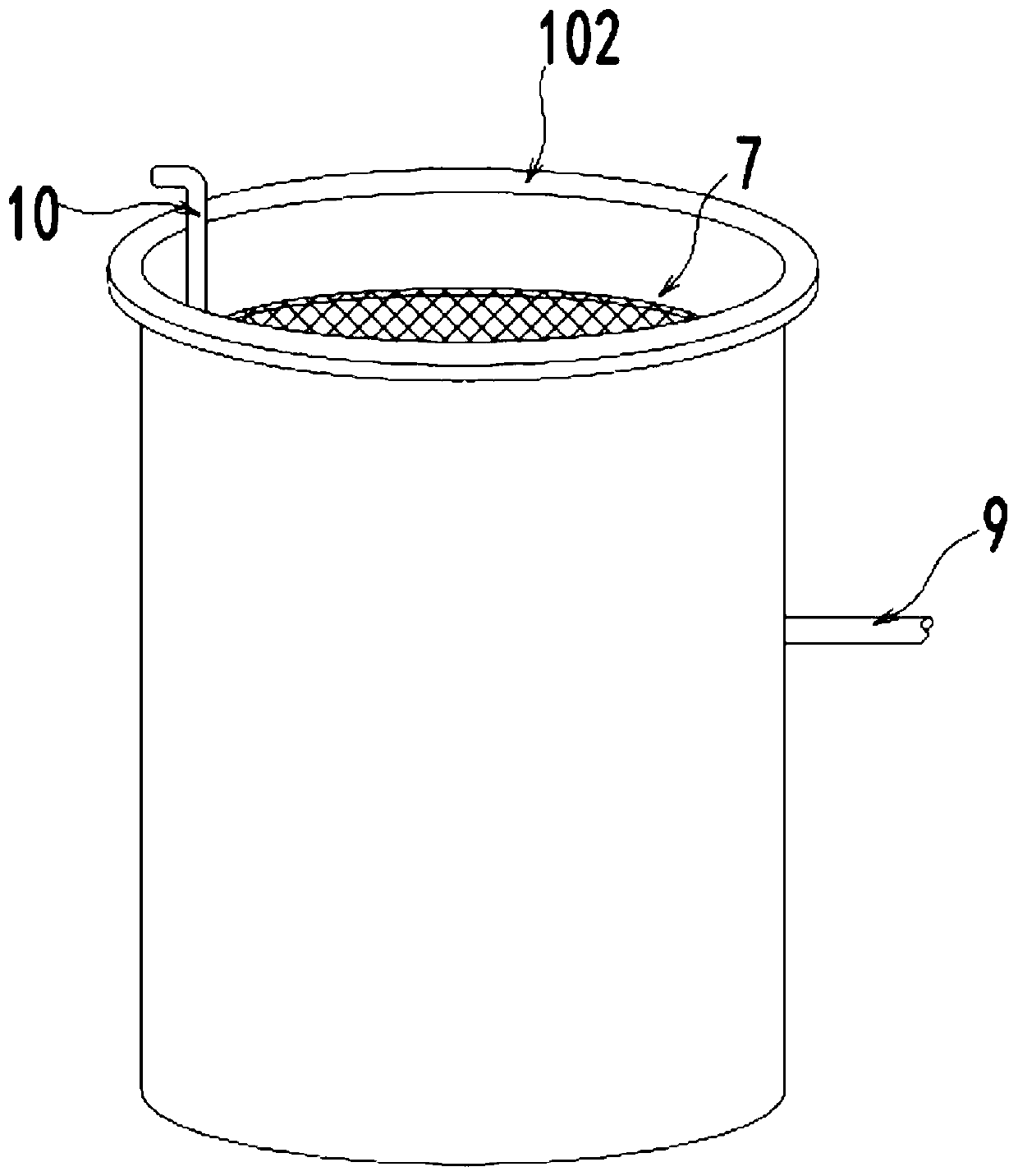

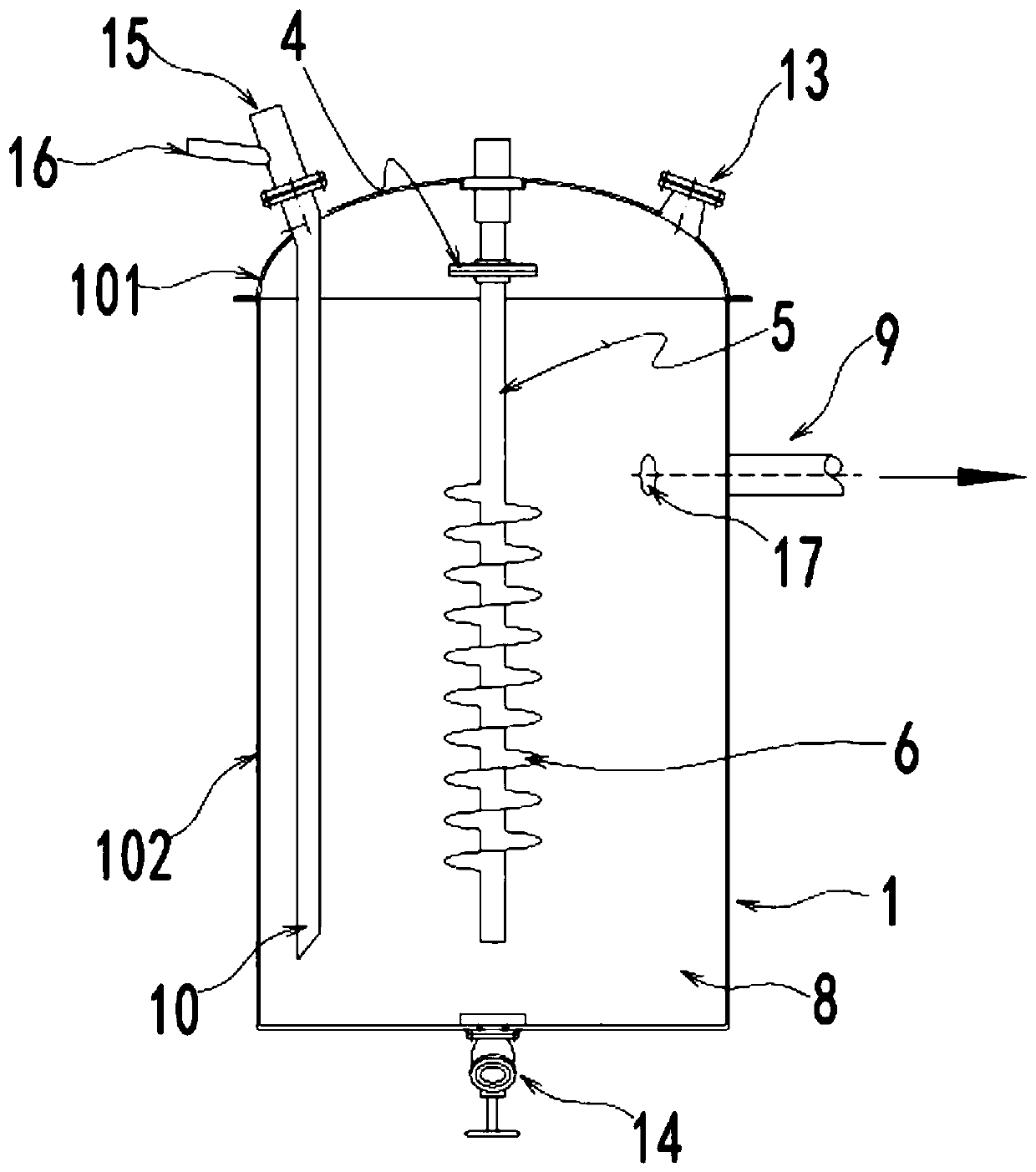

[0022] see Figure 1~3 , in an embodiment of the present invention, a soil beating mechanism includes a beating barrel 1, a motor reducer 2, a beating blade 6, an isolating cylinder 7 and a drain pipe 9, and the beating barrel 1 is fixed with an isolating cylinder coaxial with it 7. The isolation cylinder 7 is equivalent to a layer of isolation net, which is used to prevent clods, stones, etc. from entering the interior of the isolation cylinder 7. The outer wall of the isolation cylinder 7 and the inner wall of the beating barrel 1 form a beating area 8 for storing the soil mixture. The motor reducer 2 is installed on the beating barrel 1 through the motor mounting bracket 3. The beating shaft 5 is arranged in the isolation cylinder 7. The beating shaft 5 is driven to rotate by the motor reducer 2. The end of the beating shaft 5 passes through the flange plate 4 and the bolts. It is connected with the output end of the motor reducer 2, and the beating blade 6 is fixed on the ...

Embodiment 2

[0028] In an embodiment of the present invention, a soil remediation system includes the soil beating mechanism as described in the above embodiment, which can efficiently beat the soil so that pollutants such as heavy metal ions in the soil can remain in the water, and then After the water is settled, flocculated and other operations, the efficient restoration of the soil can be realized.

[0029] It should be noted that in this technical solution, by making the mud form a vortex, the internal particles of the mud collide with the soil clods during the movement, which can further promote the dissolution of the soil clods. The shock wave can make pollutants such as heavy metal ions inside the soil enter the water, which is convenient for subsequent centralized treatment; in addition, the design of the isolation cylinder 7 can prevent hard substances such as stones in the water from entering the interior of the isolation cylinder 7, and will not cause the beating blades 6 damag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com