Smart cellular composites based on ultra-low reflectivity FBG array sensors

An array sensor and composite material technology, applied in the field of aerospace honeycomb composite materials, can solve the problems of electrical sensors being susceptible to electromagnetic interference, limited signal processing in time, and difficulties in distributed measurement, achieving important social value, low loss, The effect of great economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

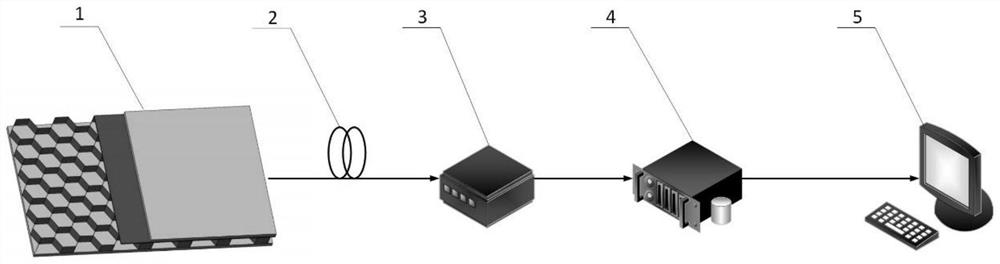

[0024] The invention provides a smart honeycomb composite material based on an ultra-low reflectivity FBG array sensor, such as figure 1 As shown, it mainly includes an optical fiber honeycomb composite material component 1 , an optical cable 2 , a data processing unit 3 , a spectrum analyzer 4 , and a computer 5 connected in sequence.

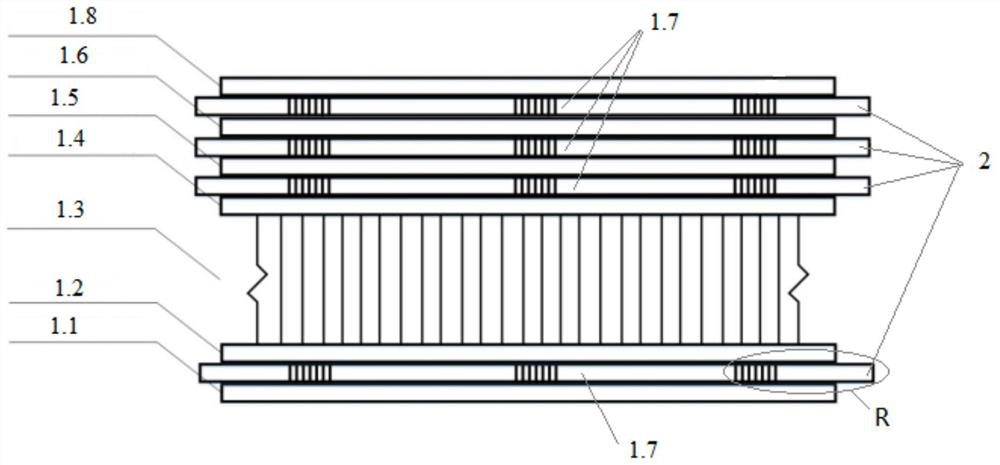

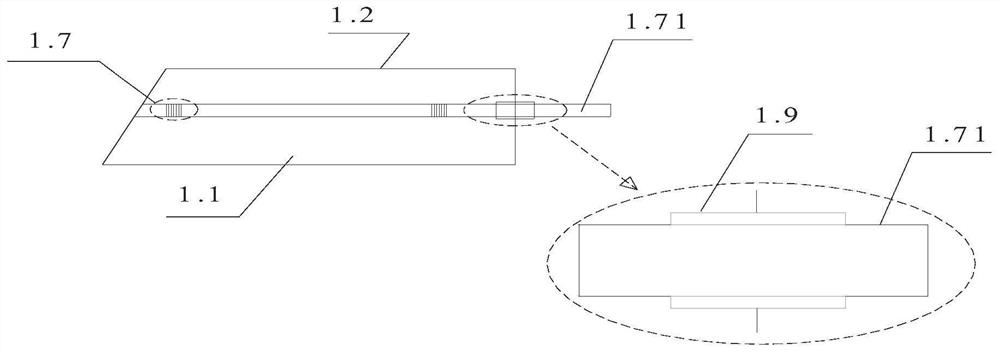

[0025] Such as figure 2 As shown, the optical fiber honeycomb composite material component 1 sequentially includes 45° inner surface prepreg 1.1, -45° inner surface prepreg 1.2, honeycomb core 1.3, the first 0° outer surface prepreg 1.4, -45° outer surface prepreg 1.5, the second 0° outer surface prepreg 1.6, 45° outer surface prepreg 1.8, an ultra-low reflectivity FBG array is fixed by an adhesive layer 1.9 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com