High-performance fair-faced concrete

A high-performance technology of fair-faced concrete, which is applied in the field of building materials, can solve the problems that the performance and appearance of fair-faced concrete cannot be balanced, and achieve the effects of reducing the risk of cracking, scientific design, and eliminating surface air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

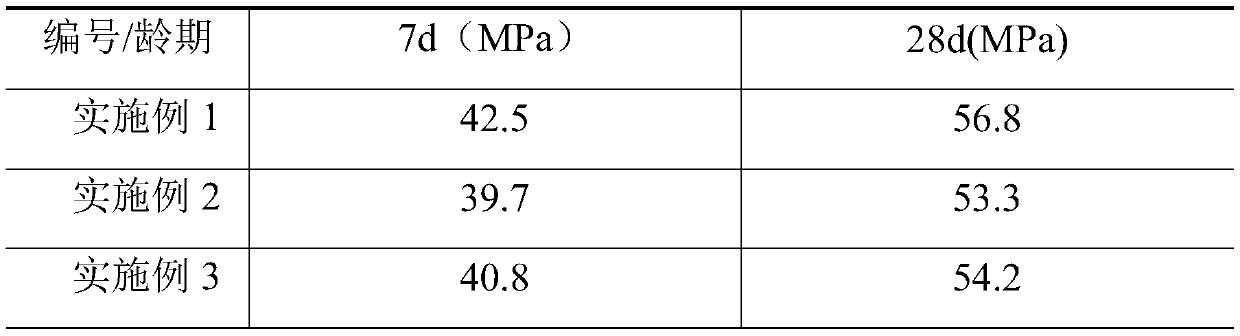

Embodiment 1

[0030] The present embodiment discloses the raw material composition of fair-faced concrete of the present invention, specifically as follows:

[0031] 430Kg of cement, 1080Kg of continuously graded limestone with a particle size of 5-25mm, 710Kg of natural silica sand with a fineness modulus of 3.0, 150Kg of domestic water, 20Kg of stone powder, 18Kg of silicon powder, 12Kg of admixture, 35Kg of expansion agent, and 1.5Kg of basalt fiber.

[0032] The admixture is made of the following raw materials: 43Kg of polycarboxylic acid, 0.4Kg of polyether, 1Kg of potassium tartrate, and 6Kg of cellulose ether.

[0033] Basalt fibers are chopped fibers with a length of 20 mm.

[0034] The fair-faced concrete prepared in this embodiment is carried out wall molding, and the result finds that the color and luster is uniform, as attached figure 1 as shown.

Embodiment 2

[0036] The present embodiment discloses the raw material composition of fair-faced concrete of the present invention, specifically as follows:

[0037] 450Kg of cement, 1050Kg of continuously graded limestone with a particle size of 5-25mm, 720Kg of natural silica sand with a fineness modulus of 2.8, 145Kg of domestic water, 15Kg of stone powder, 15Kg of silicon powder, 13Kg of admixture, 30Kg of expansion agent, and 2.0Kg of basalt fiber.

[0038] The admixture is made of the following raw materials: 48Kg of polycarboxylic acid, 0.5Kg of polyether, 3Kg of potassium tartrate, and 8Kg of cellulose ether.

[0039] Basalt fibers are chopped fibers with a length of 20 mm.

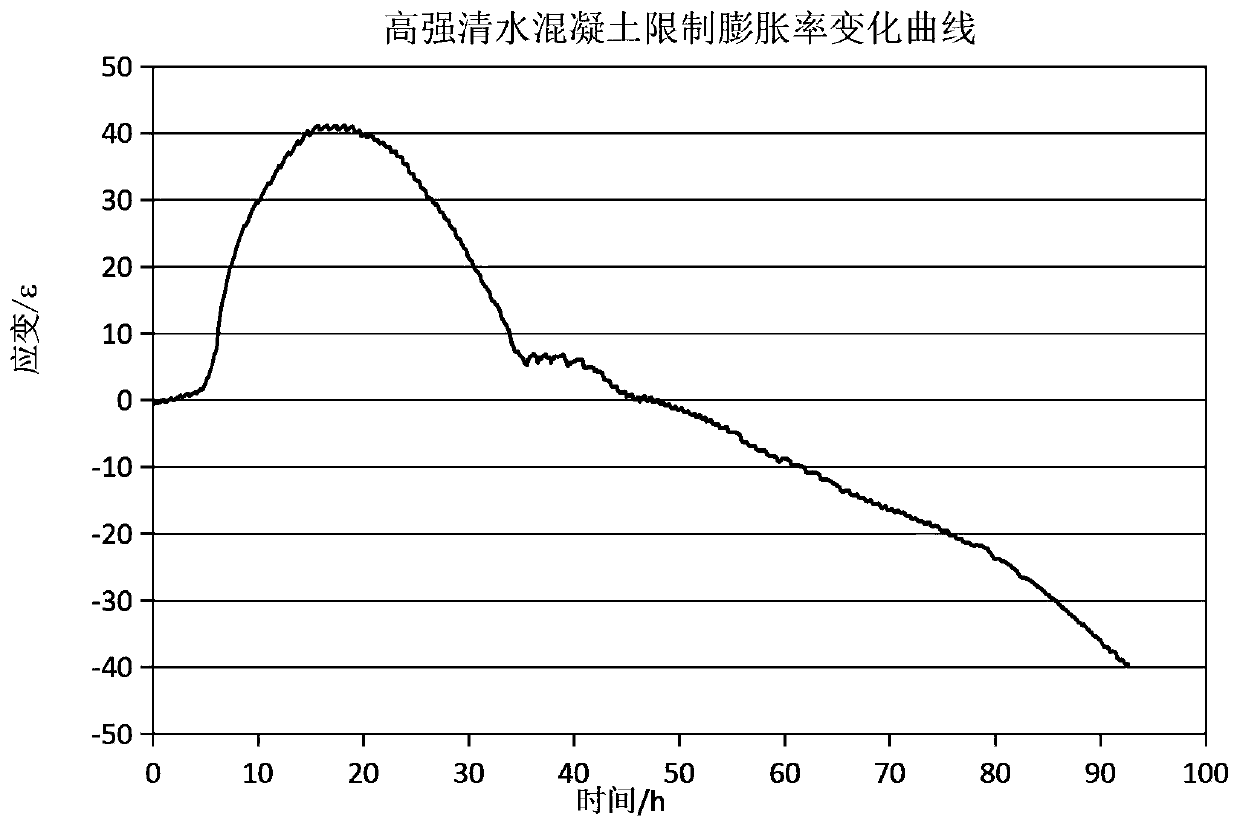

[0040] The limiting expansion rate of the fair-faced concrete of the present embodiment is tested, and the results are as attached figure 2 shown.

Embodiment 3

[0042] The present embodiment discloses the raw material composition of fair-faced concrete of the present invention, specifically as follows:

[0043] 430Kg of cement, 1050Kg of continuously graded limestone with a particle size of 5-25mm, 730Kg of natural silica sand with a fineness modulus of 3.0, 150Kg of domestic water, 20Kg of stone powder, 20Kg of silicon powder, 13Kg of admixture, 25Kg of expansion agent, and 1.5Kg of basalt fiber.

[0044] The admixture is made of the following raw materials: 40Kg polycarboxylic acid, 0.3Kg polyether, 2Kg potassium tartrate, and 2Kg cellulose ether.

[0045] Basalt fibers are chopped fibers with a length of 20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com