An automatic temperature stabilization process

An automatic and stable temperature technology, which is applied in the directions of self-melt pulling method, single crystal growth, polycrystalline material growth, etc., can solve the problems of high labor intensity, difficult operation, and long duration, so as to reduce labor intensity, High safety and productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

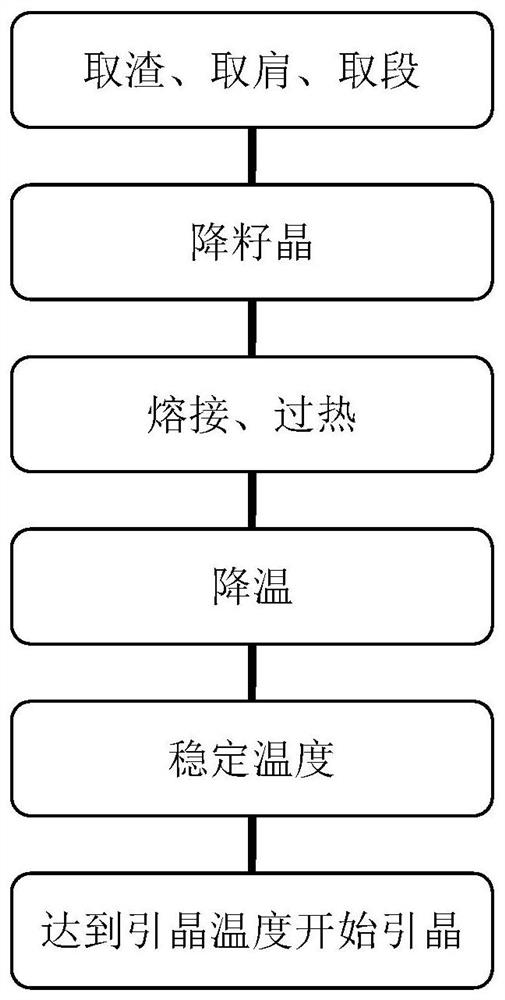

[0049] figure 1 A flow chart of an embodiment of the present invention is shown, showing the process steps of this embodiment. This embodiment relates to an automatic temperature stabilization process, which realizes automatic temperature stabilization during the Czochralski single crystal process without manual operation. Reduce labor intensity, shorten working hours for temperature stabilization, increase production capacity, avoid waste of working hours due to insufficient manual experience, high safety, and avoid abnormal accidents.

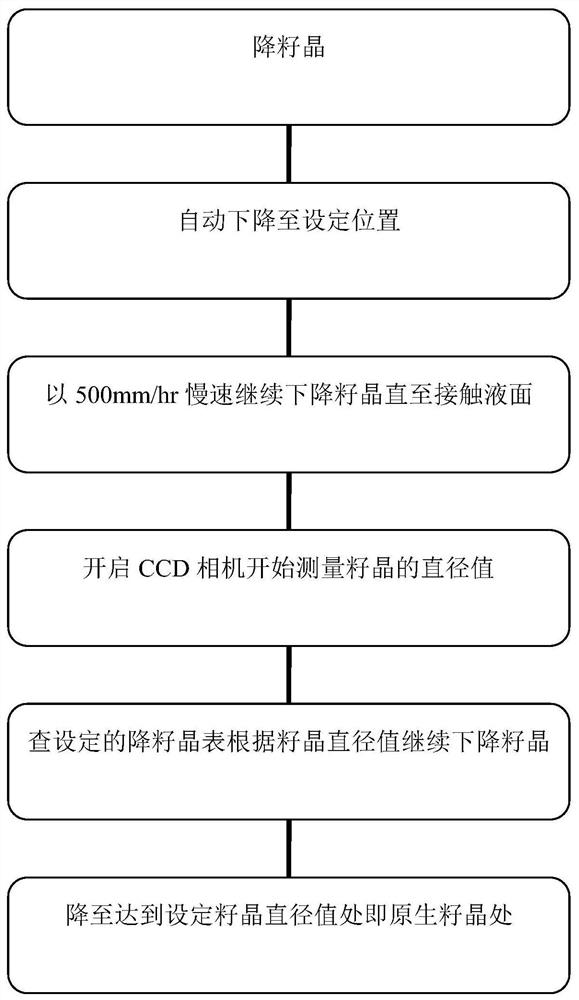

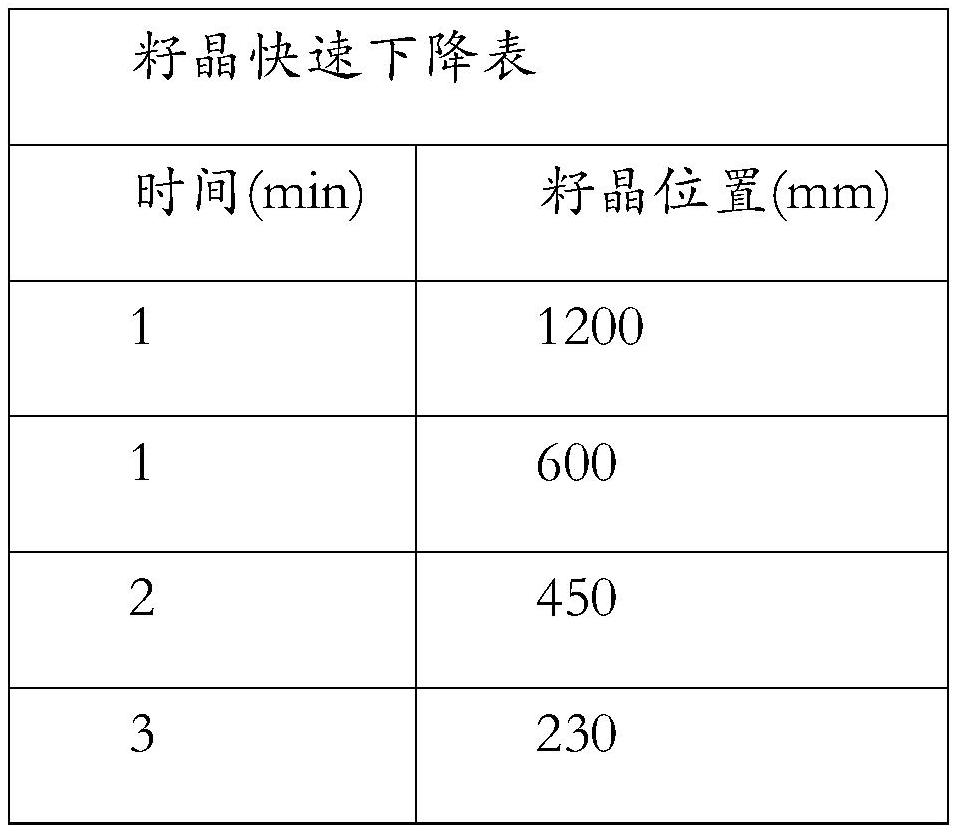

[0050] The slag is removed after re-casting, the shoulder is removed after expansion, and the section is removed after bud breaking for automatic temperature stabilization. The measuring device, control device, temperature measuring device, seed crystal voltage measuring device, seed crystal clamp, and rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com