Anti-icing ultra-durable inhaul cable

An anti-icing and sheathing technology, which is applied in the direction of cable-stayed bridges, bridge parts, bridge forms, etc., can solve the problems of cable sheath cracking, cable icing, sheath light aging, etc., to achieve convenient and fast construction, Improve the service life, the process is easy to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

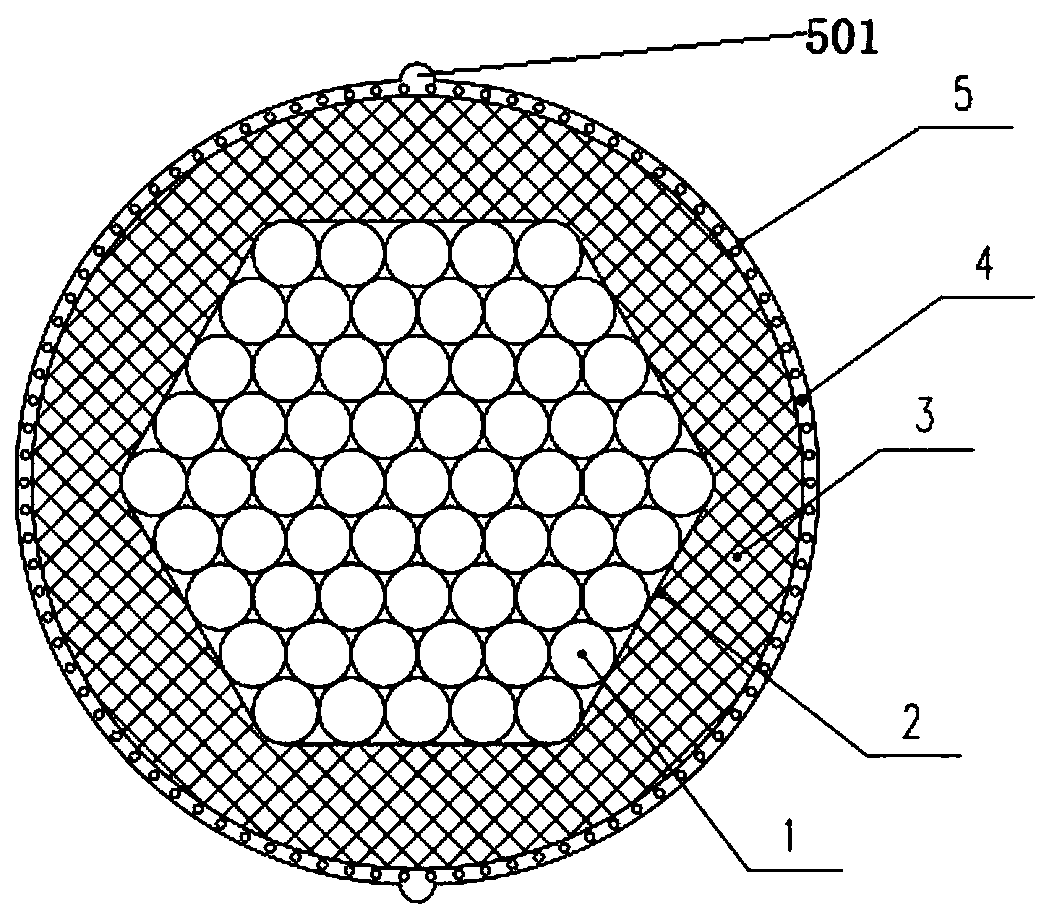

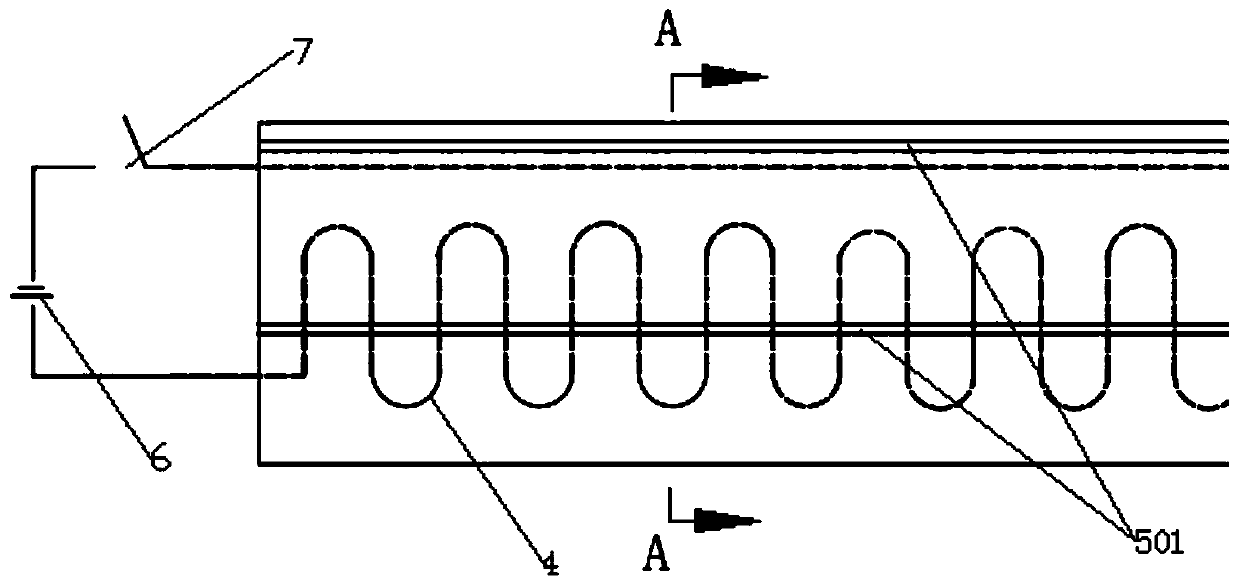

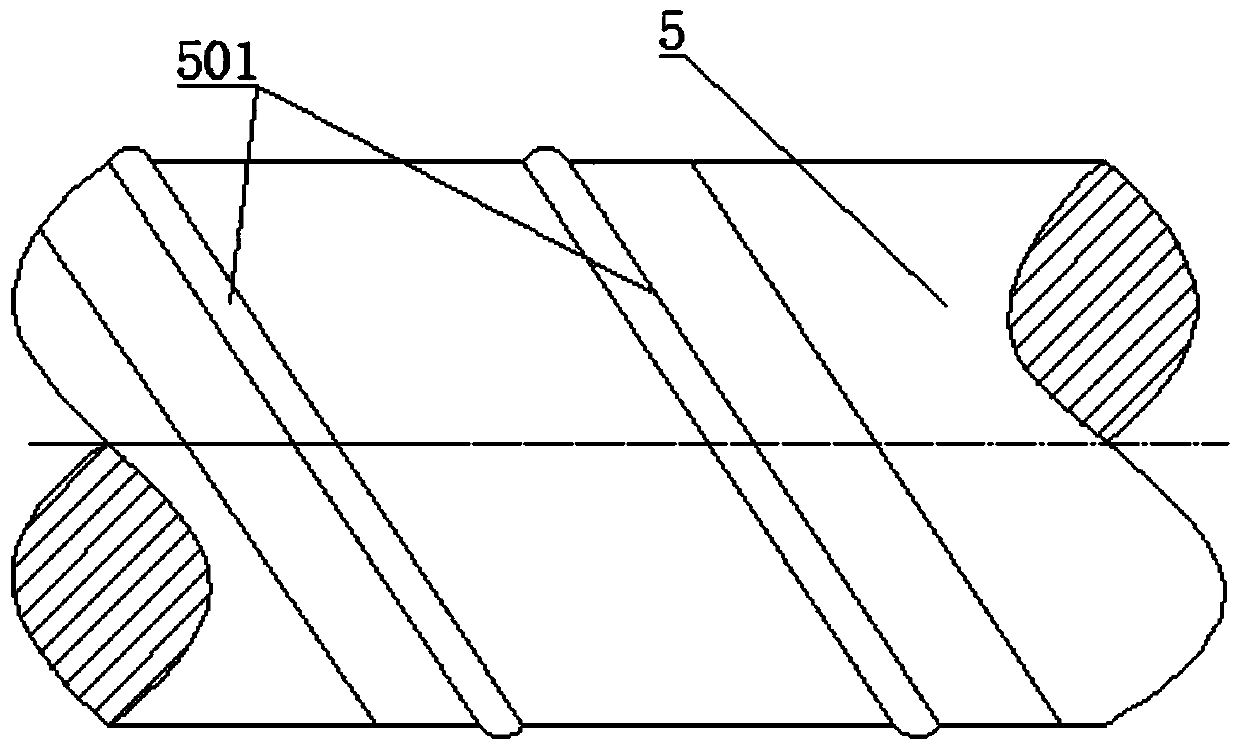

[0033] like Figure 1 ~ Figure 4 as shown in Figure 1 ~ Figure 4 As shown, an anti-icing ultra-durable cable includes the cable strand 1, the sheath 3 coated on the outer layer of the cable strand 1, and the electric heating wire 4 connected to the power supply 6 to control the electric heating The on-off switch 7 between the wire 4 and the power supply 6, the outer layer of the sheath 3 is provided with an adhesive tape 5 in a spiral winding manner, and the adhesive tape 5 is wrapped and arranged on the outer layer of the sheath 3, the adhesive tape The outer surface of 5 is provided with protruding ribs 501 along the longitudinal direction, and the electric heating wire 4 is arranged inside the adhesive tape 5 .

[0034] The anti-icing ultra-durable cable described in this implementation can control the connection between the electric heating wire 4 inside the tape and the power supply through the switch 7 in winter, so that the surface temperature of the cable can be rais...

Embodiment 2

[0036] like Figure 1 ~ Figure 4 As shown, a kind of anti-icing ultra-durable cable includes the cable strand 1, and the cable strand 1 includes a steel wire bundle and a polyester wrapping tape layer 2 coated on the outer layer of the cable strand 1, that is, the The above-mentioned polyester wrapping tape layer 2 is wound on the outer layer of the steel wire bundle to form the cable strand 1, the sheath 3 coated on the outer layer of the polyester wrapping tape layer 2, and the electric heating wire 4 connected to the power supply 6, and the control The on-off switch 7 between the electric heating wire 4 and the power supply 6, the outer layer of the sheath 3 is provided with an adhesive tape 5 in a spiral winding manner, and the adhesive tape 5 is wrapped and arranged on the outer layer of the sheath 3 , the outer surface of the adhesive tape 5 is provided with protruding ribs 501 along the longitudinal direction, and the electric heating wire 4 is arranged inside the adhes...

Embodiment 3

[0039] like image 3 , Figure 5 , Image 6 and Figure 7 As shown, a kind of anti-icing ultra-durable cable includes the cable strand 1, the cable strand 1 is a steel wire bundle, and the cable strand 1 includes a steel wire bundle and a polyester coated on the outer layer of the cable strand 1 The polyester wrapping tape layer 2, that is, the polyester wrapping tape layer 2 is wound on the outer layer of the steel wire bundle to form the cable strand 1, and the inner sheath 301 wrapped on the outer layer of the polyester wrapping tape layer 2, The outer sheath 302 covering the outside of the inner sheath 301 adopts a double-layer sheath structure, and the sheath 3 is a high-density polyethylene sheath, that is, a HDPE sheath tube.

[0040] like Image 6 As shown, this embodiment also includes an electric heating wire 4 connected to the power supply 6, a switch 7 for controlling the on-off between the electric heating wire 4 and the power supply 6, the power supply 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com