Ion beam frequency modulation method based on surface acoustic waves

A surface acoustic wave and ion beam technology, applied in electrical components, impedance networks, etc., can solve problems such as large dispersion, poor controllability of chemical frequency modulation, and low product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The purpose of this embodiment is to implement a series of processes for project 1 with high frequency accuracy (40ppm) of the sound meter project, etch project 1, frequency modulation target: require 2 pieces to reduce the target frequency 100-500Khz; 1 piece to increase the target frequency 100-500Khz .

[0029] Table 1 Comparison table before and after the implementation of item 1

[0030]

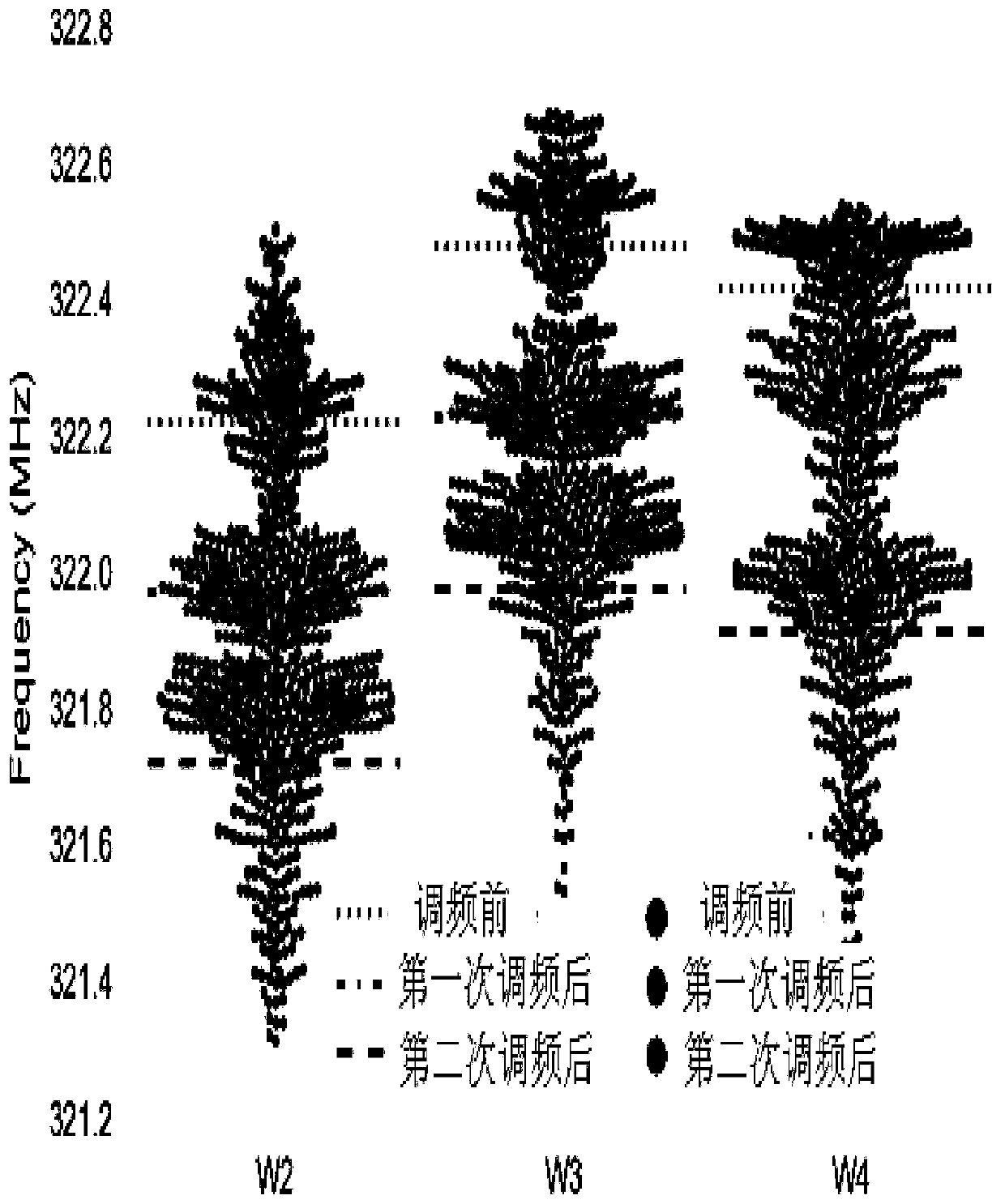

[0031] In this example, if figure 1 As shown, in order to further improve the dispersion of the device frequency and the target frequency, a second frequency modulation is performed to achieve the target frequency and reduce the frequency dispersion.

Embodiment 2

[0033] In this embodiment, a series of process implementation is carried out for item 2 with high frequency accuracy (40ppm), etching item 2, frequency modulation target: frequency control target 670.72±0.03Mhz, it is required to reduce the target frequency for 2 chips (chip 1#, 2#), 2 chips (chip 3#, 4#) can increase the target frequency, and the frequency consistency within the chip is improved.

[0034] Table 2 Comparison table before and after the implementation of project 2

[0035]

[0036] In this embodiment, the process implementation of the project with a frequency accuracy of 40ppm is verified. After frequency modulation, the target frequency is increased and decreased respectively, and the statistics figure 2 Qualification rate in , 1#, 2# wafers have a 25% pass rate before frequency modulation, and the pass rate distribution after frequency modulation is as follows image 3 ,statistics image 3 In the pass rate, the goal is achieved and the pass rate is incre...

Embodiment 3

[0038] In this embodiment, after the method of the present invention is implemented for the item 3 of the frequency accuracy 35ppm of the sound meter item, the test electrical performance analysis before and after the implementation is analyzed. In this example, Figure 4 It shows that the frequency is reduced from 275.58Mhz to 275.47Mhz after implementing the method, and the frequency of the wafer chip is increased from 275.35Mhz to 275.45Mhz after implementing the method.

[0039] The invention innovatively proposes for the first time that there is no SiO2 film on the surface in the professional production process of the acoustic meter, and the method of ion beam etching is used to increase or decrease the metal steps to achieve the purpose of reducing or increasing the frequency, and successfully solves the problem of line width and film In the production of high-frequency narrow-band surface acoustic wave devices with high thickness and high sensitivity, the use of the mos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com