Portable concrete drilling machine

A concrete and drilling machine technology, applied in the field of drilling machines, can solve the problems of high drilling efficiency and achieve the effects of high drilling efficiency, environmental protection, and convenient drilling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained by specific examples below.

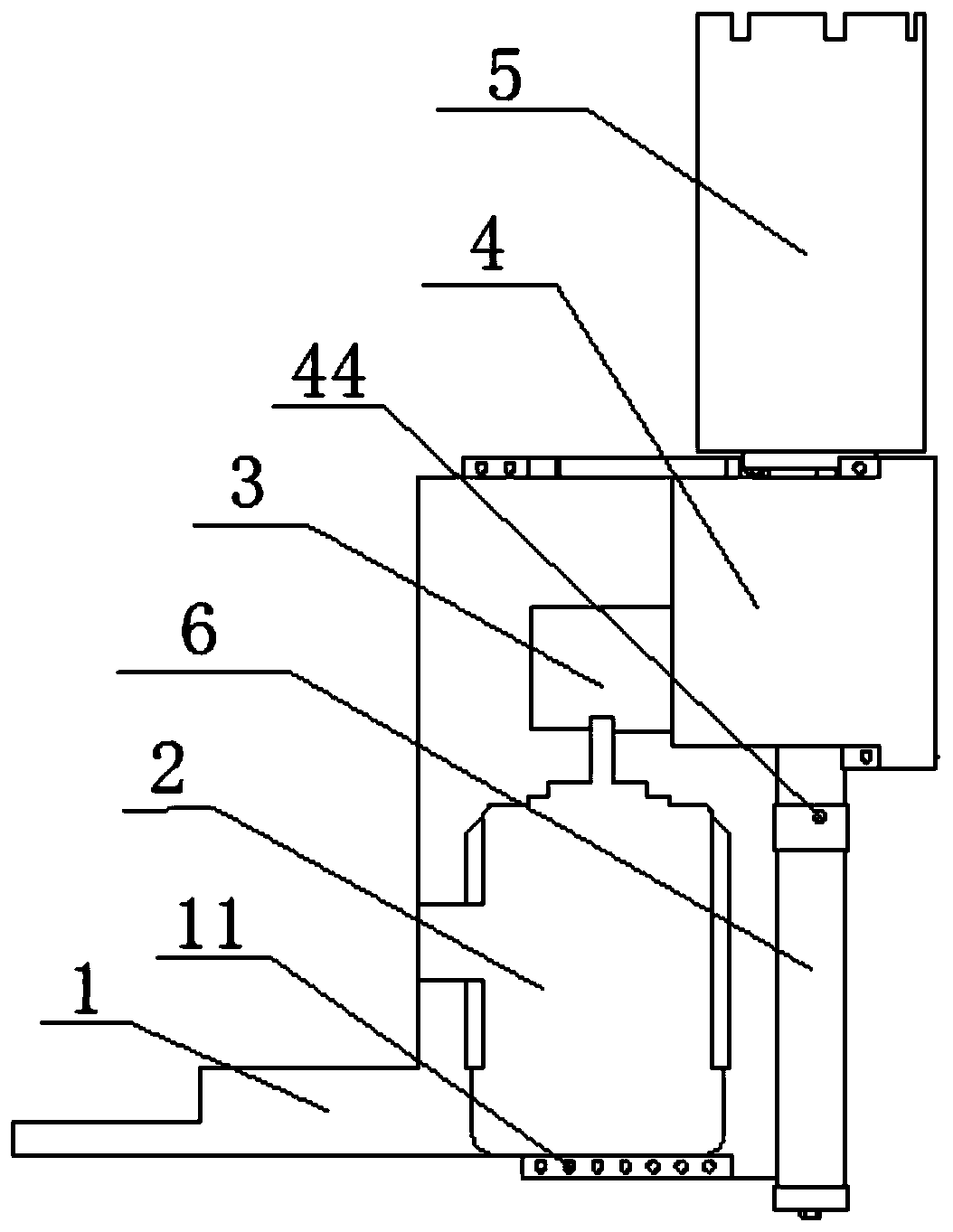

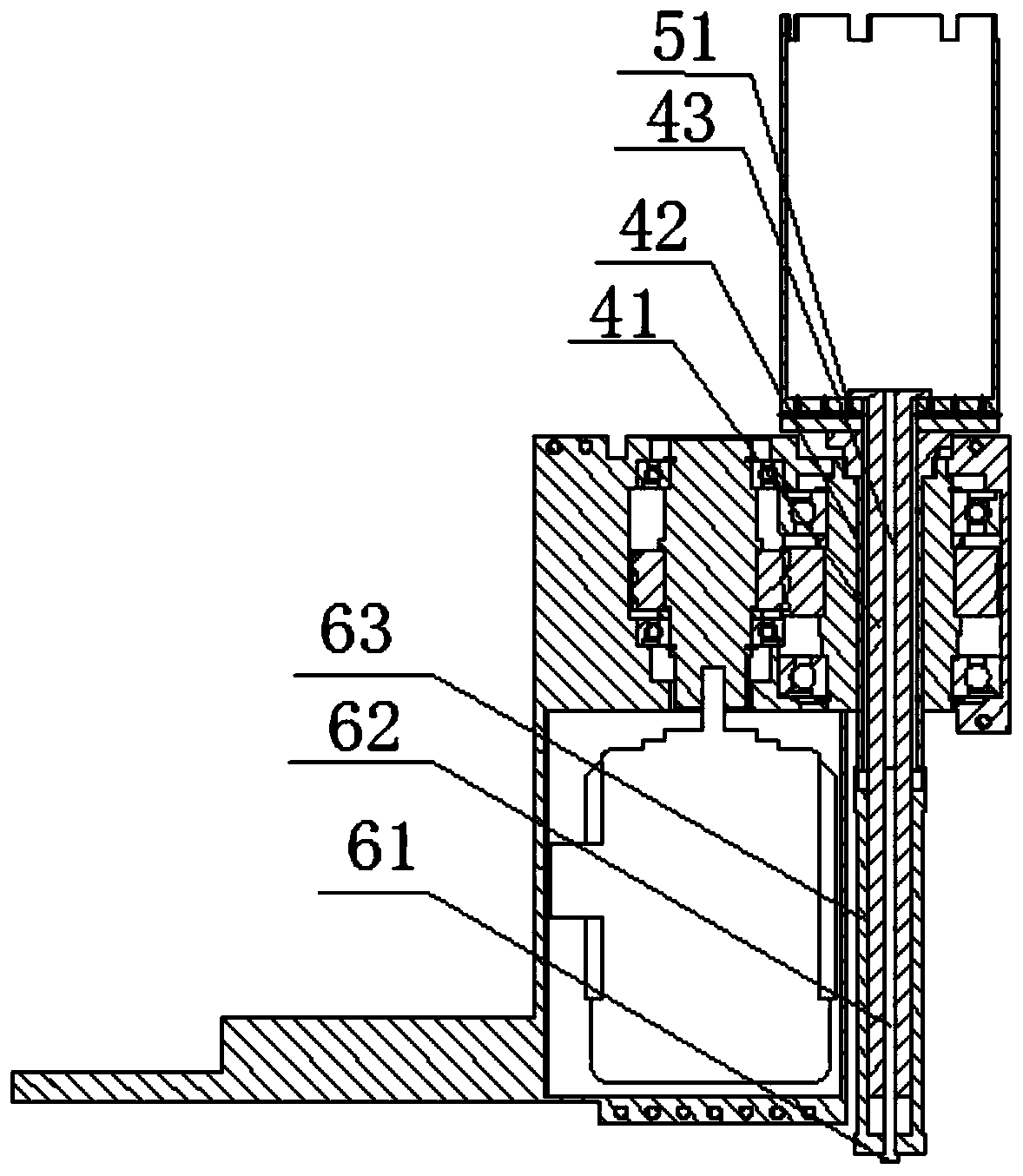

[0019] Such as figure 1 As shown, a portable concrete drilling machine includes a body frame, a motor is provided inside the body frame, a reduction box is provided on the top of the motor, and the reduction box is connected to the diamond drill bit in a threaded manner through a connecting body . At the beginning of the operation, a screw needs to be embedded in the drilling position, and the support rod is screwed to the screw. The function of the support rod is to realize the positioning of the drilling center and support most of the weight of the drilling machine. Then the drill The hole machine is connected to the support bar through the connecting body. When working, the motor rotates to drive the connecting body to rotate, thereby driving the diamond bit to rotate to complete the rotary cutting movement. The ball screw system is connected to the diamond bit through the connecting body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com