Polyurethane-rock wool composite heat insulating plate external wall external heat insulating system with rib laths

A technology of ribbed expansion mesh and external wall insulation, applied in insulation, walls, climate change adaptation, etc., can solve the problem of not meeting the performance requirements of rock wool insulation system, not solving the problem that rock wool is easy to absorb water and deliquescence, and rock wool board is not suitable and other problems, to achieve the effect of improving the external wall insulation system, lasting and stable thermal insulation performance, and improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

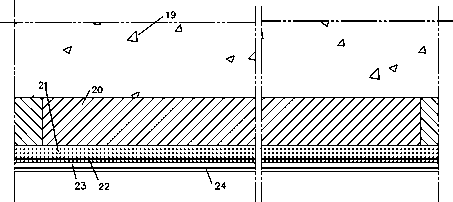

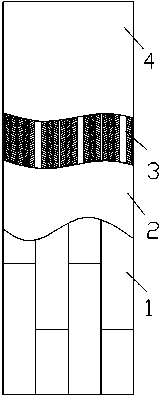

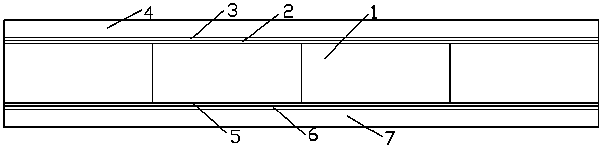

[0077] Such as Figure 2 to Figure 4 As shown, a polyurethane rock wool composite insulation board with ribbed expansion nets includes a rock wool inner core 1 formed by arranging several vertical fiber rock wool strips 8 into a flat plate, and the inner and outer surfaces of the rock wool inner core are provided with The hard foam polyurethane part I is formed by pouring the polyurethane composite material on the corresponding surface of the rock wool inner core and then foaming and curing under pressure. The hard foam polyurethane part I on each side includes hard foam covering the corresponding surface of the rock wool inner core. Foam polyurethane layer I (2 and 5) and polyurethane bond body I formed by infiltrating into the inner core of rock wool, airgel insulation mortar layer (4 and 7) is formed on each side of rigid foam polyurethane layer I, each side air The reinforcement expansion nets (3 and 6) are arranged in the gel insulation mortar layer or the reinforcement e...

Embodiment 2

[0093] Such as Figure 7 As shown, the sides around the rock wool inner core are provided with hard foam polyurethane part II11 formed by pouring polyurethane composite material on the corresponding side of the rock wool inner core and then foaming and curing under pressure. The hard foam polyurethane part II can better form a heat-resistant, isolated and waterproof layer around the outer periphery of the rock wool core.

Embodiment 3

[0095] The rigid polyurethane foam part II can also form a corresponding connection structure to expand the connectability of the composite insulation board, such as:

[0096] Such as Figure 8 As shown, in the width direction, the left and right sides of the hard foam polyurethane part II are correspondingly formed with outwardly protruding tenons and corresponding inward recessed tenon grooves 12, and the extension direction of the tenon and tenon grooves is consistent with the length direction of the rock wool inner core unanimous. The cross section of the tenon and the tenon groove is a rectangular cross section, a semicircular cross section, a triangular cross section or a special-shaped cross section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com