A lightly reduced graphene oxide nanofiltration membrane, preparation method and application thereof

A graphene nanofiltration membrane and nanofiltration membrane technology are applied in the field of mildly reduced graphene oxide nanofiltration membrane and its preparation, which can solve the problems of difficult control of reduction degree, difficult waste liquid treatment, complicated process, etc. High-efficiency water treatment capacity, low equipment requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

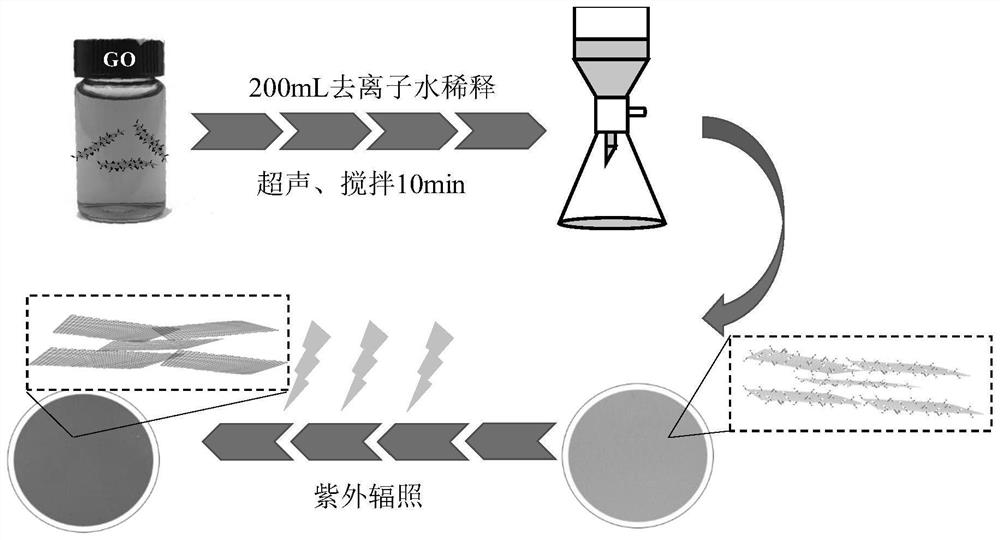

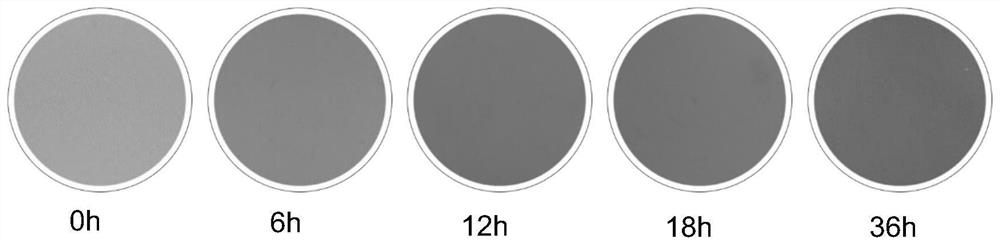

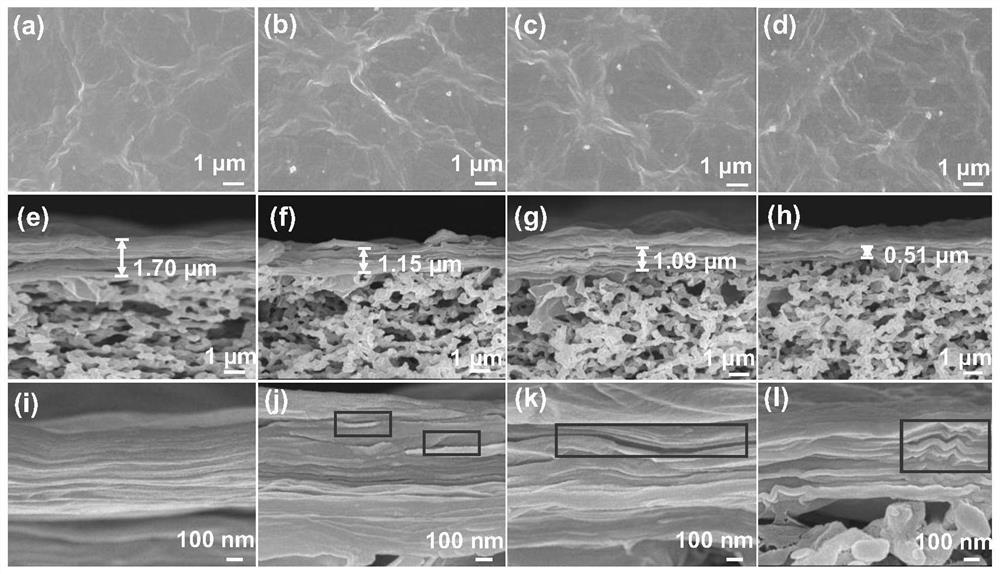

[0056] A method of preparing a mildly reduced oxide oxide noodle filter, including the following steps:

[0057] Preparation of oxidation of graphene dispersion

[0058] The oxidized graphene slurry or the oxide oxide powder is added to deionized water, and the ultrasonic frequency is 30min, and the magnetic force is stirred for 30 min, the stirring speed is 600 r / min, thereby continuous ultrasonic 30 to 40 kHz, magnetic force The stirring was stirred and the stirring speed was 600 r / min, and then the ultrasonic frequency was 30 min, the ultrasonic frequency was 30 to 40 kHz, and the magnetic force was stirred for 30 min, and the stirring velocity was 600 r / min to give a sufficiently dispersed oxide water dispersion.

[0059] Preparation of oxide oxide mean membrane

[0060] The 5 × 5 cm square PVDF diaphragm was soaked in 95% ethanol in aqueous solution of soon 30min, and was rinsed by deionized water, soaking the diaphragm after rinse is in the deionized water, and the who...

Embodiment 2

[0065] A method of preparing a mildly reduced oxide oxide noodle filter, including the following steps:

[0066] Preparation of oxidation of graphene dispersion

[0067] The oxidized graphene slurry or the oxide oxide powder is added to deionized water, and the ultrasonic frequency is 30min, and the magnetic force is stirred for 30 min, the stirring speed is 600 r / min, thereby continuous ultrasonic 30 to 40 kHz, magnetic force The stirring was stirred and the stirring speed was 600 r / min, and then the ultrasonic frequency was 30 min, the ultrasonic frequency was 30 to 40 kHz, and the magnetic force was stirred for 30 min, and the stirring velocity was 600 r / min to give a sufficiently dispersed oxide water dispersion.

[0068] Preparation of oxide oxide mean membrane

[0069] The 5 × 5 cm square PVDF diaphragm was soaked in 95% ethanol in aqueous solution of soon 30min, and was rinsed by deionized water, soaking the diaphragm after rinse is in the deionized water, and the who...

Embodiment 3

[0074] A method of preparing a mildly reduced oxide oxide noodle filter, including the following steps:

[0075] Preparation of oxidation of graphene dispersion

[0076]The oxidized graphene slurry or the oxide oxide powder is added to deionized water, and the ultrasonic frequency is 30min, and the magnetic force is stirred for 30 min, the stirring speed is 600 r / min, thereby continuous ultrasonic 30 to 40 kHz, magnetic force The stirring was stirred and the stirring speed was 600 r / min, and then the ultrasonic frequency was 30 min, the ultrasonic frequency was 30 to 40 kHz, and the magnetic force was stirred for 30 min, and the stirring velocity was 600 r / min to give a sufficiently dispersed oxide water dispersion.

[0077] Preparation of oxide oxide mean membrane

[0078] The 5 × 5 cm square PVDF diaphragm was soaked in 95% ethanol in aqueous solution of soon 30min, and was rinsed by deionized water, soaking the diaphragm after rinse is in the deionized water, and the whol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com