Coal water slurry purification pre-conversion furnace

A coal-water slurry and pre-transformation technology, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, and gas dedusting, etc., can solve the problems of big safety risks and high cost of agent change operation, and achieves extended operation period and reduced number of agent changes. , the effect of lower replacement costs and operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

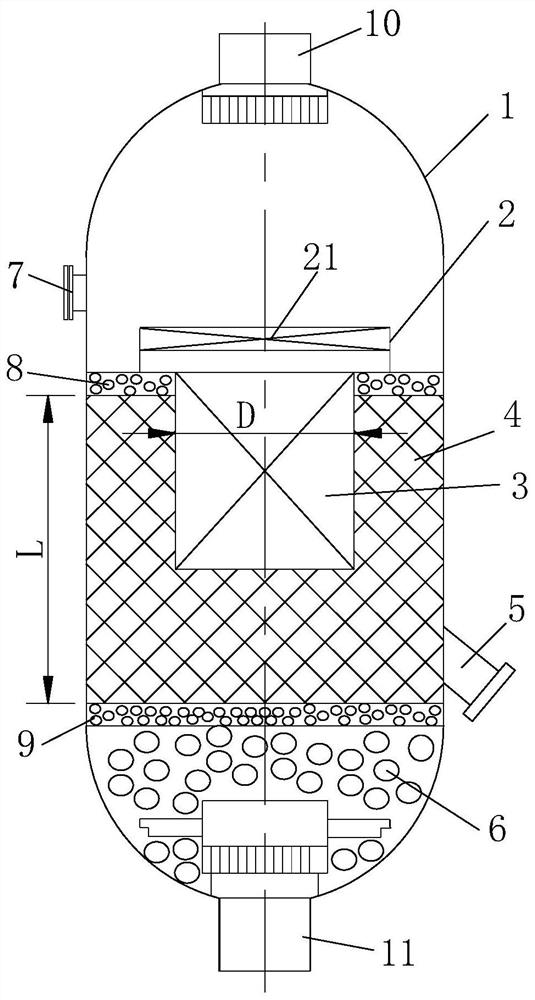

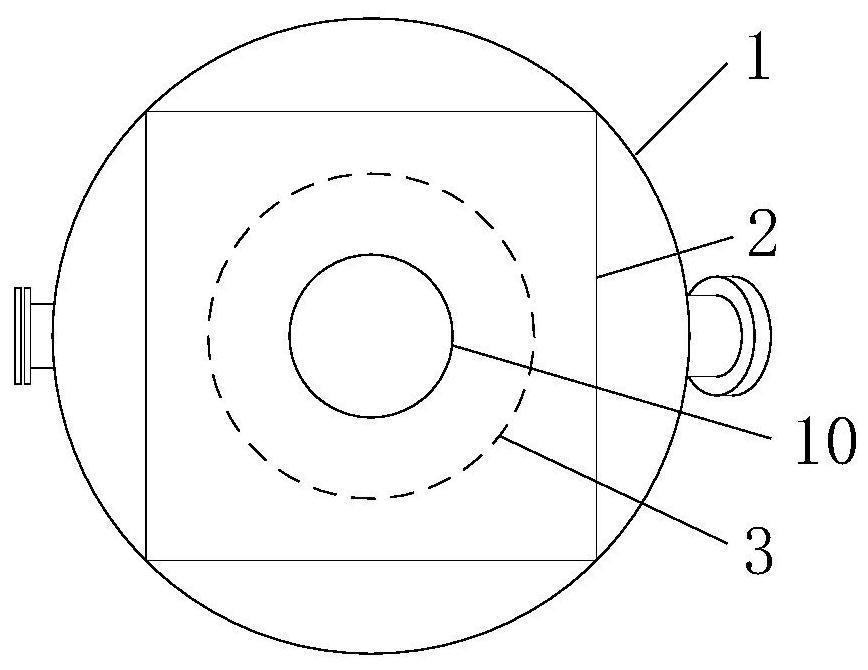

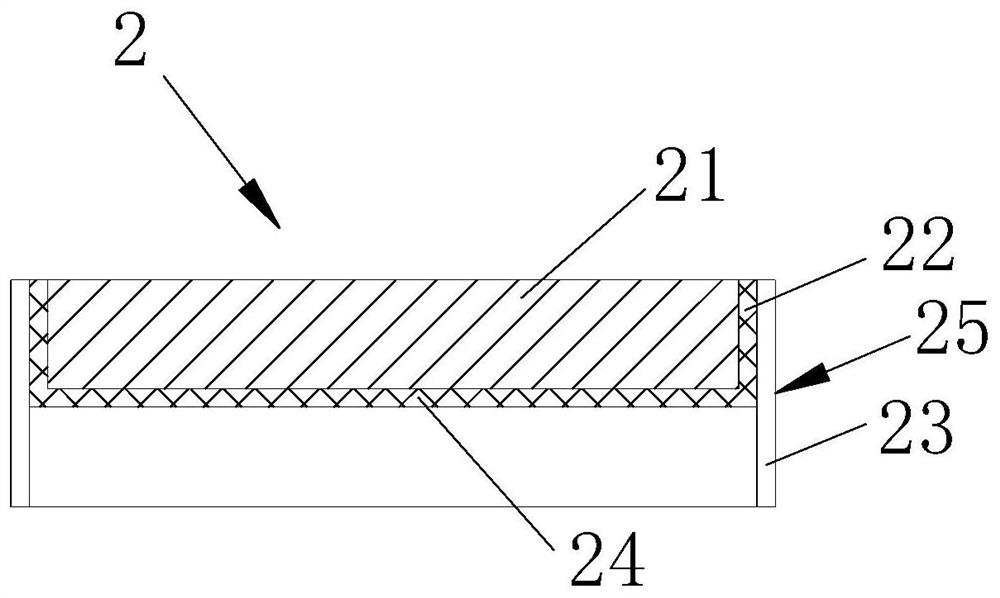

[0023] refer to figure 1 and figure 2 , a coal-water slurry purification pre-conversion furnace, which includes a furnace body 1 and a dirt collection basket 2 and a distribution basket 3 arranged in the furnace body 1, the inner peripheral surface of the furnace body 1 is circular, and the furnace body 1 An air inlet 10 is arranged at the center of the top, an exhaust outlet 11 is arranged at the bottom of the furnace body 1 , and a manhole 7 and a discharge hole 5 are arranged on the furnace body.

[0024] The furnace body is sequentially filled with a proppant layer 6, a lower alumina ceramic ball layer 9, a pre-change protective agent layer 4, and an upper alumina ceramic ball layer 8 laid on the upper side of the pre-change protective agent layer 4 from the bottom to the top. 7 is located on the upper side of the upper alumina ceramic ball layer 8, and the discharge hole 5 is used to discharge the pre-change protection agent in the pre-change protection agent layer 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com