Electromagnetic pure iron part with transparent water-soluble protective film and preparation method of electromagnetic pure iron part

An electromagnetic pure iron, water-soluble technology, applied in the field of iron parts, can solve problems such as poor surface protection effect, achieve the effect of avoiding withstand voltage, reducing difficulty and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of the electromagnetic pure iron parts with transparent water-soluble protective film of the present invention, specifically implement according to the following steps:

[0043] Step 1, mixing higher fatty acids, polyols, organic amines, carboxylates, and pure water, and stirring evenly to obtain a protective solution;

[0044] The proportion of each component in the protective solution is: 0.5% higher fatty acid, 0.5% polyol, 0.35% organic amine, 0.1% carboxylate, 98.55% pure water;

[0045] The higher fatty acid is lauric acid; the polyol is neopentyl glycol; the organic amine is piperazine; the carboxylate is ammonium propionate;

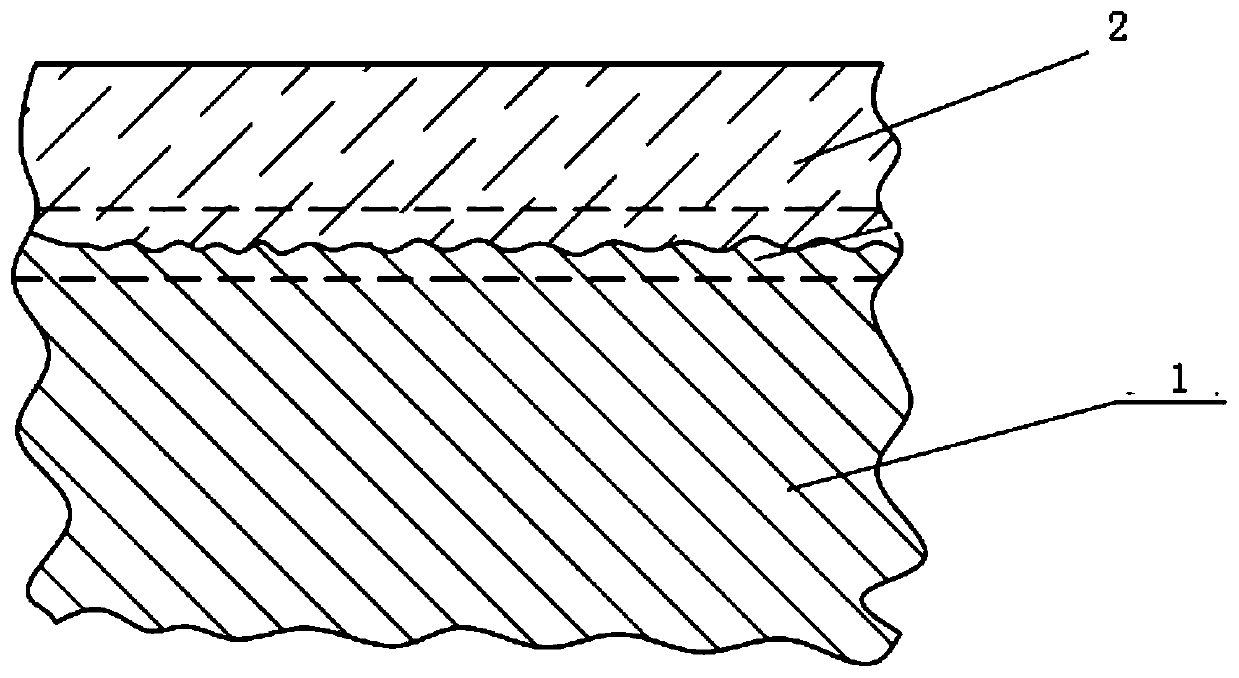

[0046] Step 2, put the electromagnetic pure iron part body 1 into the protective liquid and make the surface of the electromagnetic pure iron part body 1 fully wet, then remove the electromagnetic pure iron part body 1 from the protective liquid and dry it, and put the liquid drop on the electromagnetic pure ir...

Embodiment 2

[0048] A kind of preparation method of the electromagnetic pure iron parts with transparent water-soluble protective film of the present invention, specifically implement according to the following steps:

[0049] Step 1, mixing higher fatty acids, polyols, organic amines, carboxylates, and pure water, and stirring evenly to obtain a protective solution;

[0050] The proportion of each component in the protective solution is: higher fatty acid 0.8%, polyol 0.6%, organic amine 0.4%, carboxylate 0.2%, pure water 98%;

[0051] The higher fatty acid is myristic acid; the polyol is trihydroxymethylpropane; the organic amine is p-methylaniline; the carboxylate is iron acetate;

[0052]Step 2, put the electromagnetic pure iron part body 1 into the protective liquid and make the surface of the electromagnetic pure iron part body 1 fully wet, then remove the electromagnetic pure iron part body 1 from the protective liquid and dry it, and put the liquid drop on the electromagnetic pure ...

Embodiment 3

[0054] A kind of preparation method of the electromagnetic pure iron parts with transparent water-soluble protective film of the present invention, specifically implement according to the following steps:

[0055] Step 1, mixing higher fatty acids, polyols, organic amines, carboxylates, and pure water, and stirring evenly to obtain a protective solution;

[0056] The proportion of each component in the protective solution is: 0.9% of higher fatty acid, 0.7% of polyol, 0.55% of organic amine, 0.25% of carboxylate, and 97.6% of pure water;

[0057] The higher fatty acid is palmitic acid; the polyol is neopentyl glycol; the organic amine is piperazine; the carboxylate is ammonium propionate;

[0058] Step 2, put the electromagnetic pure iron part body 1 into the protective liquid and make the surface of the electromagnetic pure iron part body 1 fully wet, then remove the electromagnetic pure iron part body 1 from the protective liquid and dry it, and put the liquid drop on the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com