A kind of bamboo wood material modification method and a kind of bamboo wood board

A technology of wooden boards and bamboo wood, which is applied in the field of bamboo wood material modification and bamboo wood boards, can solve the problems of complicated operation, unstable anti-corrosion and anti-mildew effect, etc., and achieves simple and easy operation, stable anti-corrosion and anti-mildew effect, and improved The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

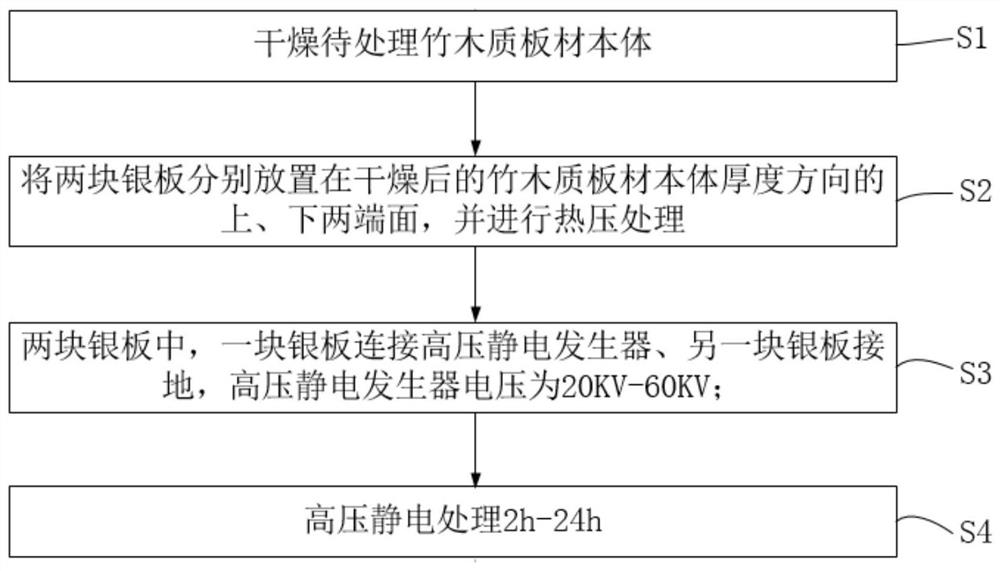

[0057] (1) Sample preparation

[0058] The wood material is made of a sample sheet having a specification of 50 mm × 50 mm × 20 mm (length × width x height).

[0059] (2) Sample high pressure static electricity

[0060] 1) Dry the wood sample sheet, and the hydration rate of the wood sample sheet after drying is 5%.

[0061] 2) Subcombody is carried out on the surface of the wax sample sheet after step 1), and the amount of sand is 0.3 mm.

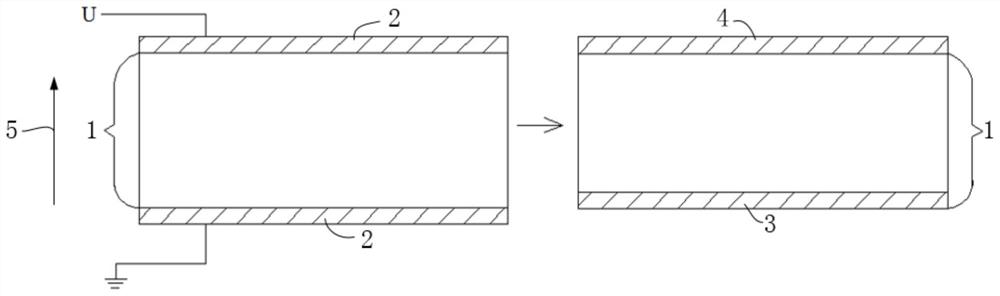

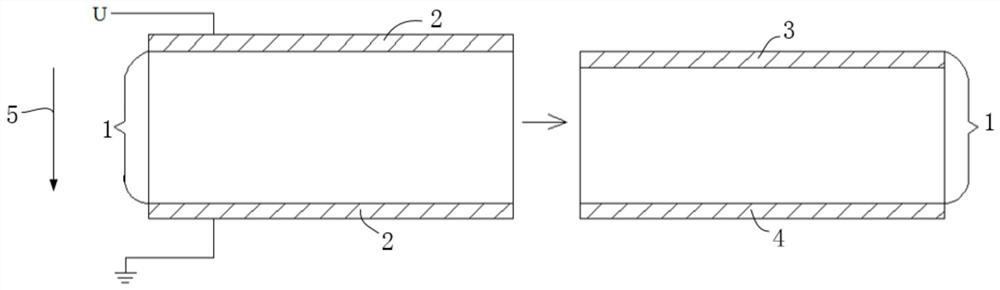

[0062] 3) The silver plate 2 of two 55 mm × 55 mm × 2 mm (length × width × height) is placed on the upper and lower end faces of the thickness of the wood sample sheet, and the silver plate 2 is 92.5%. The hot press is placed together, and the heat pressure treatment is performed. The hot press temperature is set to normal temperature (no heating), and the plate surface pressure is set to 0.1 MPa.

[0063] 4) The upper silver plate 2 on the wood sample sheet is connected to the high pressure electrostatic generator negative electrode, the volt...

Embodiment approach 25

[0078] (1) Sample preparation

[0079] The bamboo material is made of a sample sheet having a specification of 50 mm × 50 mm × 10 mm (length × width × height).

[0080] (2) Sample high pressure static electricity

[0081] 1) Dry the bamboo sample sheet, and the end water content of the bamboo sample sheet after drying is 11%.

[0082] 2) Substocetal treatment on the surface of the bamboo sample sheet after step 1), and the amount of sand is 0.5 mm.

[0083] 3) Silver plate 2 of two 55 mm × 55 mm × 2 mm (length × width × height) is placed on the thickness direction of the sheet after drying, the lower end surface, the silver plate 2 is 95.0. %, Put it into a hot press with a hot press treatment, and the hot press is provided to normal temperature (no heating), and the pressure is set to 0.1 MPa. It should be noted that the remaining silver plate 2 remains repeatedly utilized after high pressure static processing.

[0084] 4) The upper silver plate 2 of the bamboo sample sheet is co...

Embodiment 49

[0099] (1) Sample preparation

[0100] 7 layers of bamboo composite laminate: the upper and lower surfaces of a poplar monogram, the secondary layer of the lower surface is 2.5mm thick bamboo sheet, the average gap between the bamboo pieces is 3mm wide, the remaining 4 layers It is also a 1.5mm thick poplar single board. The laying method of the laminate is orthogonal laving, and the remaining upper and lower surface layers are laid in the embedded direction of 0 °, which is made of 50mm × 50mm × 20mm (length × wid) Highly) bamboo composite laminate test plate.

[0101] (2) Sample high pressure static electricity

[0102] 1) Dry the bamboo composite laminate test plate material, and the hydration rate of the wood sample sheet after drying is 8%.

[0103] 2) Substochondrion treatment on the surface of the bamboo composite laminate sample sheet of step 1), and the amount of sand is 0.4 mm.

[0104] 3) Two 55 mm × 55 mm × 2 mm (length × width × height) silver plate 2 is placed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com