Transparent fast- forming low-hardness thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and low-hardness technology, applied in the field of low-hardness thermoplastic polyurethane elastomer and its preparation, can solve problems such as difficulty in obtaining transparency, inability to meet processing requirements, and limit the application of low-hardness products, and achieve low hardness and good formability , good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

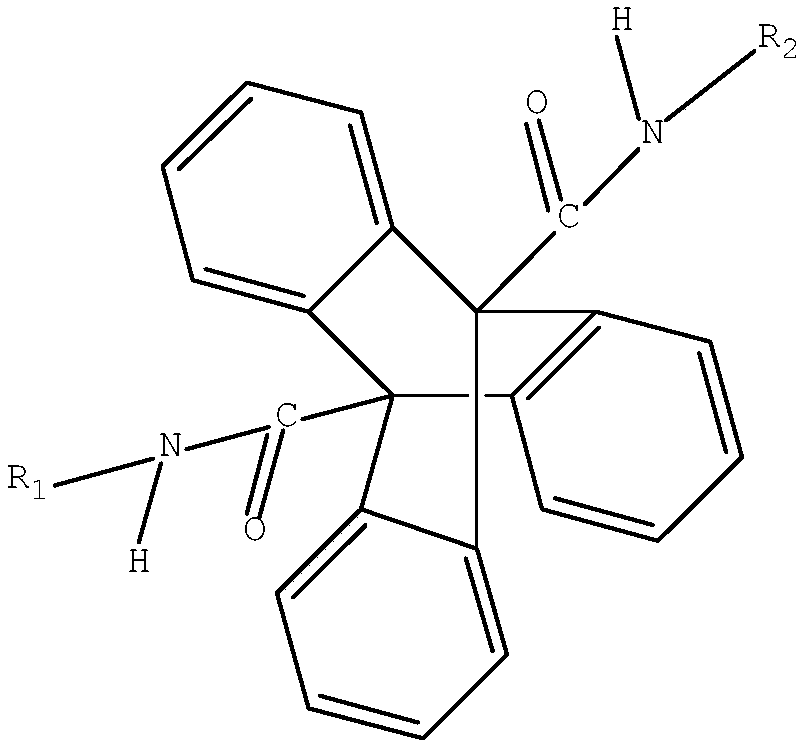

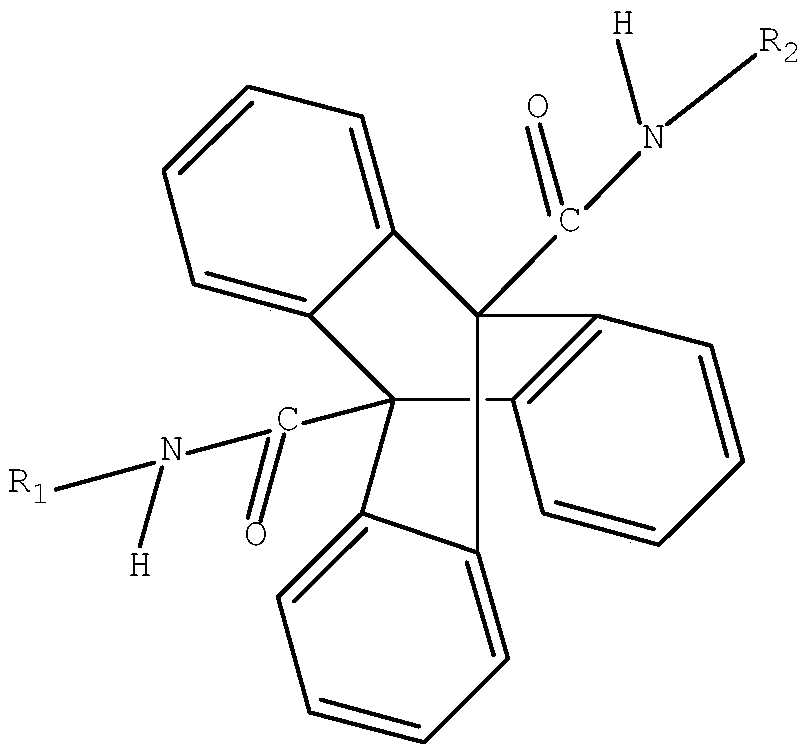

[0017] A low-hardness thermoplastic polyurethane elastomer with transparent molding fast, its components include by weight: 70 parts of PBA polyester polyol (molecular weight is 1500), chain extender (R 1 , R 2 Both are 10 parts of OH) and 20 parts of toluene diisocyanate.

[0018] The performance test of the obtained thermoplastic polyurethane elastomer is shown in Table 1.

Embodiment 2

[0020] A low-hardness thermoplastic polyurethane elastomer with transparent molding fast, its components include by weight: 75 parts of PEA polyester polyol (molecular weight is 2000), chain extender (R 1 for OH, R 2 for NH 2 ) 8 parts and 17 parts of diphenylmethane diisocyanate.

[0021] The performance test of the obtained thermoplastic polyurethane elastomer is shown in Table 1.

Embodiment 3

[0023] A low-hardness thermoplastic polyurethane elastomer with transparent molding fast, its components include by weight: 75 parts of PEBA polyester polyol (molecular weight is 1000), chain extender (R 1 for OH, R 2 for NH 2 ) 6 parts and 19 parts of dicyclohexylmethane diisocyanate.

[0024] The performance test of the obtained thermoplastic polyurethane elastomer is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com