A kind of tearable film and preparation method thereof

A technology of coating and parts by weight, which is applied in the field of casting film, can solve the problems of consumers who are inconvenient to tear the coating, difficult to tear continuously, and unable to tear the coating, so as to reduce the risk of bacterial infection and reduce the risk of tearing. The effect of cracking strength and strong inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

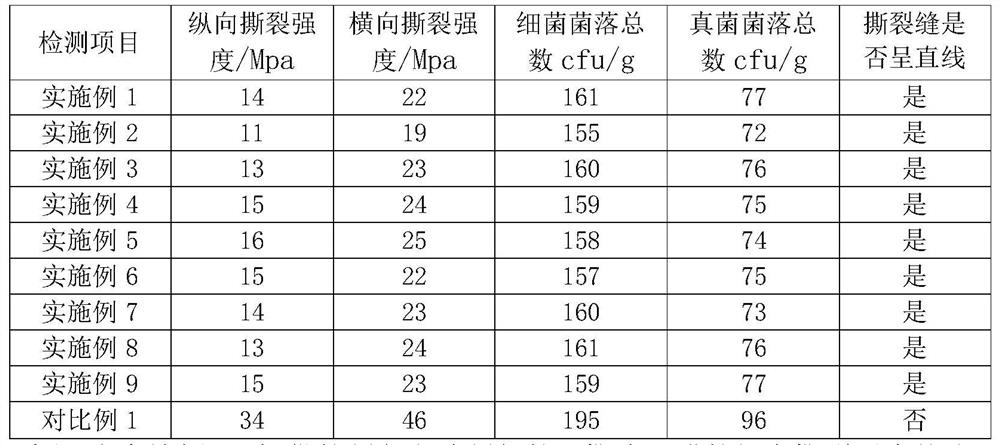

Examples

Embodiment 1

[0027] A preparation method of tearable film, comprising the following steps:

[0028] S1: Mixing and extrusion plasticization: According to the ratio of parts by weight, 12 parts of LDPE, 17 parts of LLDPE, 52 parts of HDPE, 13 parts of PP, 3 parts of metallocene polyethylene, 0.5 parts of lubricant, 1.8 parts of dispersant, antibacterial agent 4 parts, 3 parts of crystallization nucleating agent, 2 parts of color masterbatch are mixed evenly and put into the extruder; among them, the antibacterial agent includes 0.5 parts of tea polyphenol, 5 parts of chitin fiber; the crystallization nucleating agent includes dibenzylidene sorbic acid 3 parts of alcohol, 4 parts of p-hydroxybenzoic acid, 2 parts of poly-4-methoxy-4'-acryloyloxybenzoic acid phenyl ester; then adjust the temperature of the extruder to 160 ° C, and keep it for 25 minutes, plasticized, extrusion;

[0029] S2: Extrusion casting: connect, filter, and cast in sequence, wherein the temperature of the connecting pr...

Embodiment 2

[0033] A preparation method of tearable film, comprising the following steps:

[0034] S1: mixing and extrusion plasticization: according to the ratio of parts by weight, 16 parts of LDPE, 14 parts of LLDPE, 56 parts of HDPE, 11 parts of PP, 4 parts of metallocene polyethylene, 1.5 parts of lubricant, 1.2 parts of dispersant, antibacterial agent 6 parts, 2 parts of crystallization nucleating agent, 4 parts of color masterbatch are mixed evenly and put into the extruder; among them, the antibacterial agent includes 1.8 parts of tea polyphenol, 3 parts of chitin fiber; the crystallization nucleating agent includes dibenzylidene sorbic acid 4.5 parts of alcohol, 2.5 parts of p-hydroxybenzoic acid, 3.5 parts of poly-4-methoxy-4'-acryloyloxybenzoic acid phenyl ester; then adjust the temperature of the extruder to 165 ° C and keep it for 30 minutes to plasticize. extrusion;

[0035] S2: Extrusion casting: connect, filter, and cast processes in sequence, wherein the temperature of t...

Embodiment 3

[0039] A preparation method of tearable film, comprising the following steps:

[0040]S1: Mixing and extruding plasticization: According to the ratio of parts by weight, 19 parts of LDPE, 10 parts of LLDPE, 65 parts of HDPE, 8 parts of PP, 5 parts of metallocene polyethylene, 2 parts of lubricant, 0.3 parts of dispersant, antibacterial agent 8 parts, 0.5 parts of crystallization nucleating agent, 5 parts of color masterbatch are mixed evenly and put into the extruder; among them, the antibacterial agent includes 3 parts of tea polyphenols, 1 part of chitin fiber; the crystallization nucleating agent includes dibenzylidene sorbic acid 6 parts of alcohol, 1 part of p-hydroxybenzoic acid, 2 parts of poly-4-methoxy-4'-acryloyloxybenzoic acid phenyl ester; then adjust the temperature of the extruder to 170 ° C, and keep it for 35 minutes, plasticized, extrusion;

[0041] S2: Extrusion casting: connect, filter, and cast in sequence, wherein the temperature of the connecting process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com