Optimization method for blast furnace blowing of high-calcium bituminous coal based on ash melting characteristics

An optimization method, calcium bituminous coal technology, applied in blast furnaces, flow characteristics, blast furnace details, etc., can solve problems such as tuyere slagging, low ash melting point, and unclear optimization methods, and achieve the effect of expanding resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

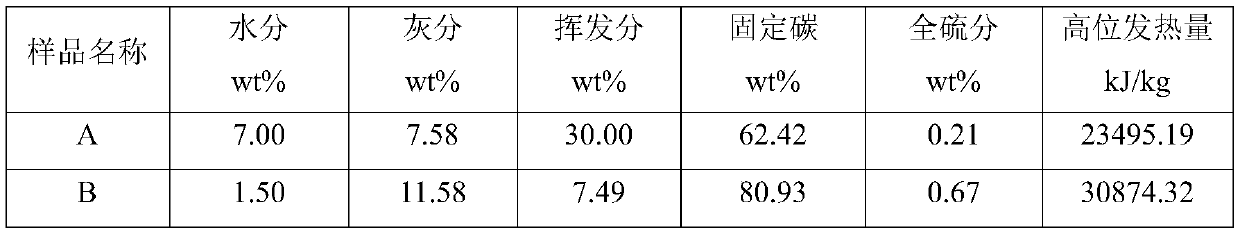

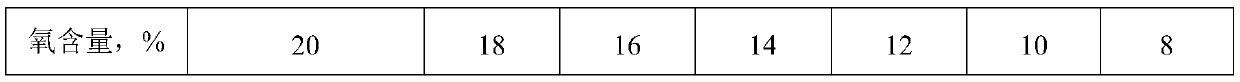

[0045] A high-calcium bituminous coal A and a commonly used blast furnace injection anthracite B were selected, and the basic characteristics and injection process characteristics of the two coal powders were experimentally measured according to the above method. The measurement results are as follows:

[0046] Table 1 Industry-wide analysis of pulverized coal

[0047]

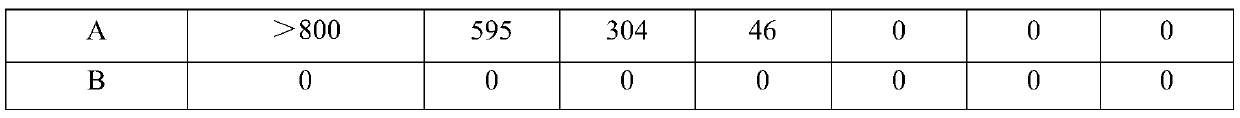

[0048] Table 2 Elemental analysis of pulverized coal

[0049] sample name C H N S O A 74.59 3.95 0.76 0.21 12.64 B 81.20 3.11 1.24 0.67 2.09

[0050] Table 3 Ash composition analysis of pulverized coal

[0051] sample name SiO 2

Al 2 o 3

Fe 2 o 3

CaO MgO TiO 2

SO 3

P 2 o 5

K 2 o

Na 2 o

A 21.17 10.64 22.92 31.70 0.89 0.39 8.72 0.04 1.07 1.35 B 53.05 35.69 2.55 2.36 0.32 1.87 0.70 1.12 0.71 1.05

[0052] Table 4 Determination results of pulverized coal Hastelloy grindability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com