Method for preparing hypoglycemic peptide by using Flammulina velutipes

A technology of Flammulina velutipes and hypoglycemia, which is applied in the field of bioengineering, can solve the problems of lack of high value-added products, backward processing technology of Flammulina velutipes, unfavorable sustainable development of Flammulina velutipes, etc., to achieve increased utilization value, strong industrial implementation, and strong inhibition of a- Effect of glucosidase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

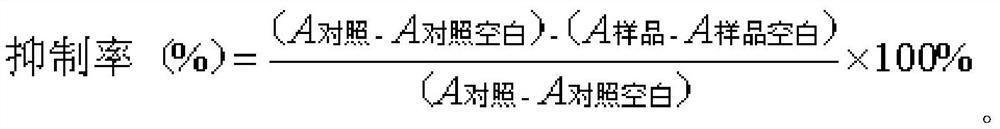

Examples

Embodiment 1

[0029] Embodiment 1, a kind of method utilizing Flammulina velutipes to prepare hypoglycemic peptide, carries out following steps successively:

[0030] 1), Weigh 2kg of Flammulina velutipes dry powder, add 24kg of 0.5% sodium hydroxide aqueous solution to mix, extract at 60°C for 2h, take the supernatant, adjust the pH value of the supernatant to 4.0 with 1moL / L HCl, 8000r / min Freeze (4°C) and centrifuge for 15 minutes to obtain 0.5kg of precipitate,

[0031] 2), add 1.5kg of water to the precipitate obtained in step 1) and stir evenly, use 0.1mol / L sodium hydroxide to adjust the pH to 7.0, heat up to 45°C, then add 5.0g of neutral protease (100U / mg), Enzymolysis reaction at 45°C for 3 hours under shaking conditions (180r / min);

[0032] 3), heat up the enzymolysis reaction product obtained in step 2) to 95-100° C. within 10 minutes, maintain this temperature for 15 minutes, and cool it down to room temperature naturally. Centrifuge at 4°C for 20 minutes, and the supernatant...

Embodiment 2

[0043] Embodiment 2, a kind of method utilizing Flammulina velutipes to prepare hypoglycemic peptide, carries out following steps successively:

[0044] 1), Weigh 5kg of Flammulina velutipes dry powder, add 60kg of 0.5% sodium hydroxide aqueous solution to mix, extract at 60°C for 2h, take the supernatant, adjust the pH value of the supernatant to 4.0 with 1moL / L HCl, 8000r / min Freeze (4°C) and centrifuge for 15 minutes to obtain 1.3kg of precipitate;

[0045] 2), add 6.5kg of water to the precipitate obtained in step 1) and stir evenly, use 0.1mol / L sodium hydroxide to adjust the pH value to 7.5, heat up to 50°C, then add 13.0g of neutral protease (100U / mg), Enzymolysis reaction at 50°C for 4 hours under shaking conditions (180r / min);

[0046] Subsequent steps are the same as in Example 1.

[0047] The obtained Flammulina velutipes hypoglycemic peptide powder is slightly yellow in color. Configured as a 3mg / mL solution, the measured inhibitory activity on a-glucosidase was 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com