Steam recycling system and method in polysilicon production

A technology of polysilicon and steam, applied in the direction of polycrystalline material growth, crystal growth, steam superheating, etc., can solve the problems of waste of water resources, high cost, waste of heat, etc., and achieve the effect of saving production costs and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

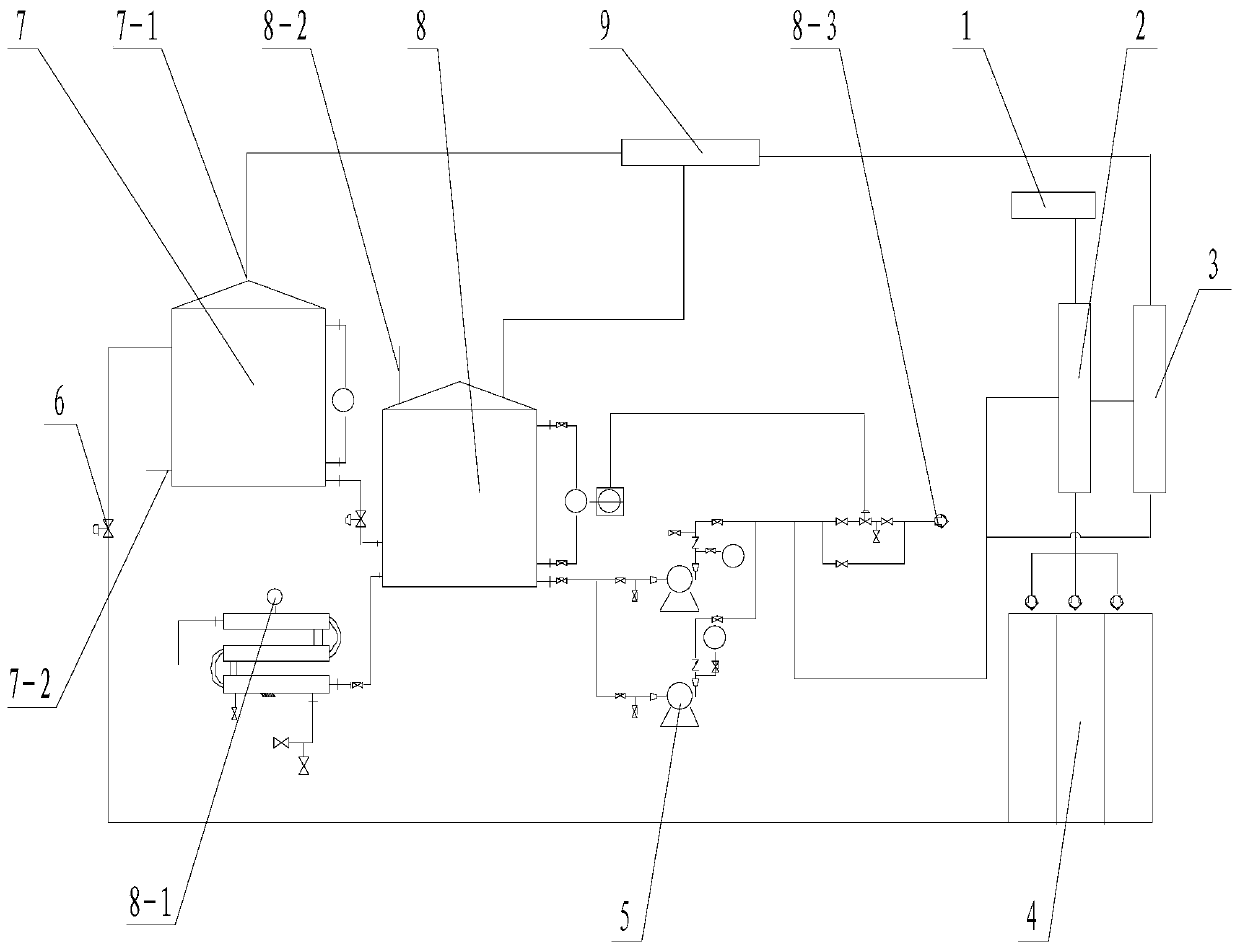

[0041] Such as figure 1 As shown, on the one hand, an embodiment of the present invention provides a steam recycling system in polysilicon production, comprising: a superheated saturated steam source 1, a temperature and pressure reducer, a saturated steam utilization device, a steam condensate storage tank 8, a flash The steamer 7 and the high-temperature wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com