Evaporation mask, OLED display substrate, fabrication method of OLED display substrate and display device

A technology for display substrates and manufacturing methods, applied in the directions of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of increasing the production time and production cost of OLED display panels, and reduce production costs and reduce production costs. Time, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

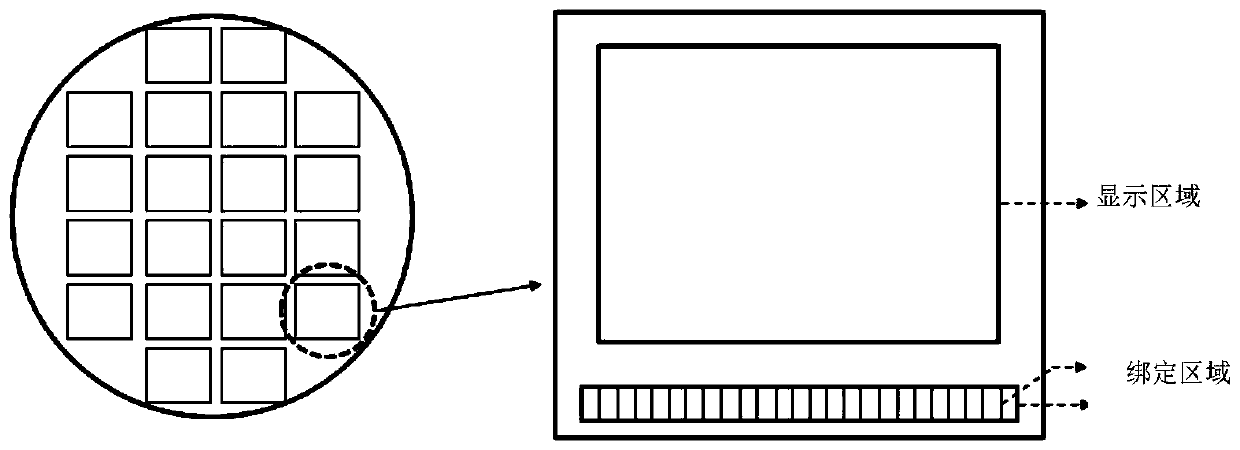

[0047] figure 1 It is a schematic diagram of the layout of the OLED display substrate on the silicon wafer, such as figure 1 As shown in the left half of , the silicon wafer is provided with multiple OLED display substrates arranged in an array; as figure 1 As shown in the right half of , a single OLED display substrate mainly includes a display area and a bonding area, wherein the bonding area is composed of a plurality of bonding pads, which are used as input signals of the OLED display substrate As with output channels, the bonding pads are made of metal.

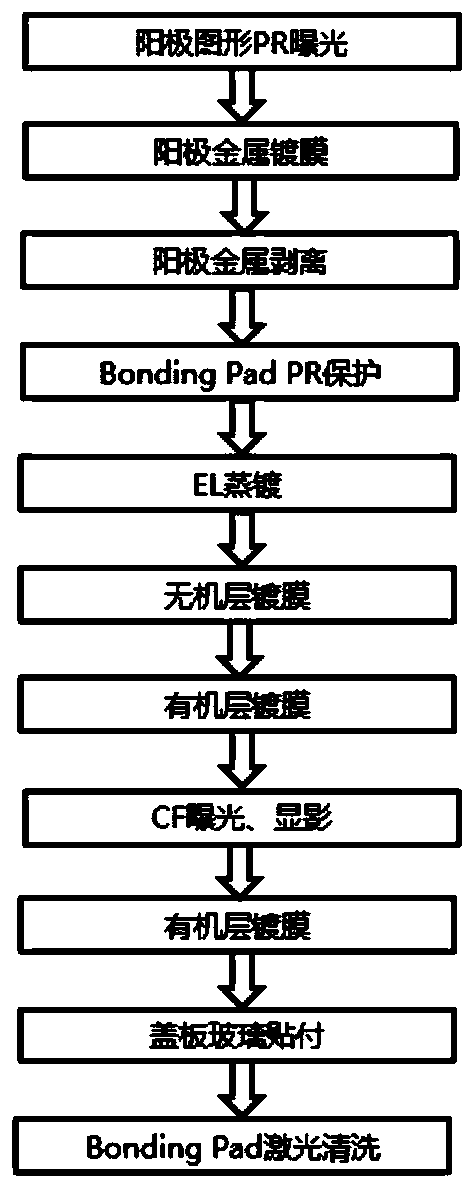

[0048] figure 2 It is a schematic diagram of the production process of the existing silicon-based OLED display panel, such as figure 2 As shown, the existing silicon-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com