A layered deployment intelligent soil cultivation equipment for crop growth and its working method

A crop growth and intelligent technology, applied in application, soil material testing, general control system, etc., can solve the problems of large body loss, insufficient fertilizer utilization, poor mechanical operation quality, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

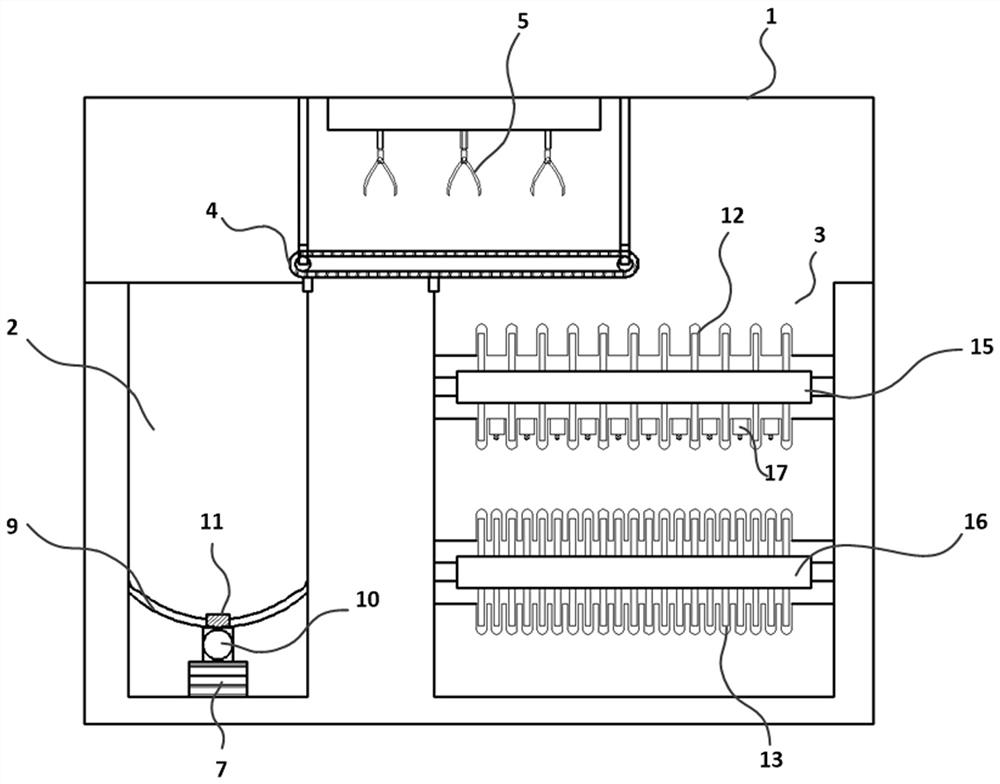

[0065] Such as Figure 1-9 As shown, this embodiment provides a layered deployment intelligent soil cultivation equipment for crop growth, including a soil cultivation mechanism and a control mechanism.

[0066] Cultivation agencies include:

[0067] Car body 1, the interior of car body 1 is divided into two interconnected semi-enclosed spaces, which are respectively transfer room 2 and processing room 3, and a transfer device 4 is arranged between the transfer room 2 and the processing room 3, and the transfer device 4 The input end is arranged at the upper edge position of the transfer room 2, and its output end is arranged at the upper center position of the processing room 3, and the transfer device 4 forms a horizontal transmission channel for transferring the soil from the transfer room 2 to the processing room 3, and the horizontal transfer The top of the passage is provided with a number of lift-type electric grippers 5, which are used to pick out solid impurities in ...

Embodiment 2

[0094] Such as Figure 1-9 As shown, the present embodiment provides a working method for layered deployment of intelligent soil cultivation equipment for crop growth, including the following working steps:

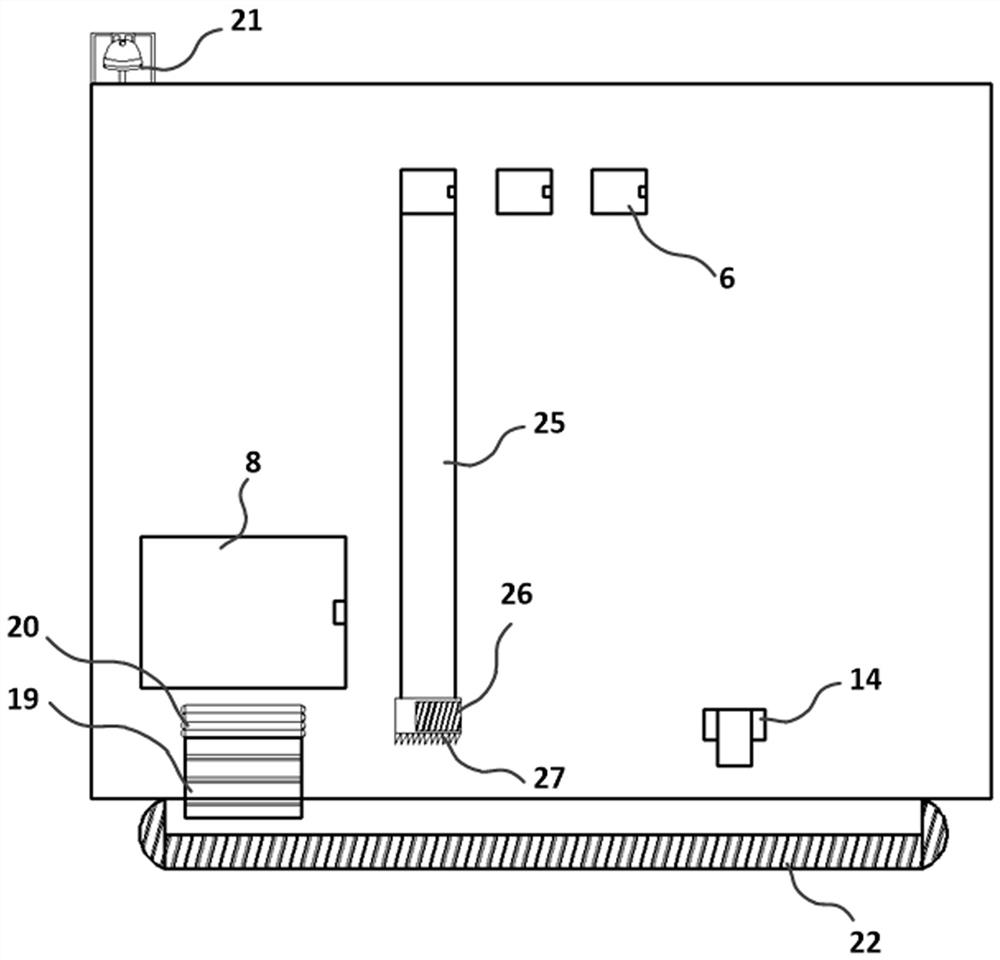

[0095] S101 : Setting a preset crop, the camera device 21 acquires the surrounding environment of the vehicle body 1 and sends the captured image to the processor 23 .

[0096] S102: The processor 23 determines whether there is a preset crop in the captured image.

[0097] S103: If yes, the processor 23 analyzes the growth form of the preset crop and the soil depth corresponding to the growth state, and outputs an excavation signal to the driving device 24, and the driving device 24 drives the tipping device 20 to start, and the tipping device 20 drives the electric bucket 19 to The soil above the preset crop root system is transferred to the unloading soil plate 9.

[0098] S104: The processor 23 outputs a vibration signal to the driving device 24, and the driving devi...

Embodiment 3

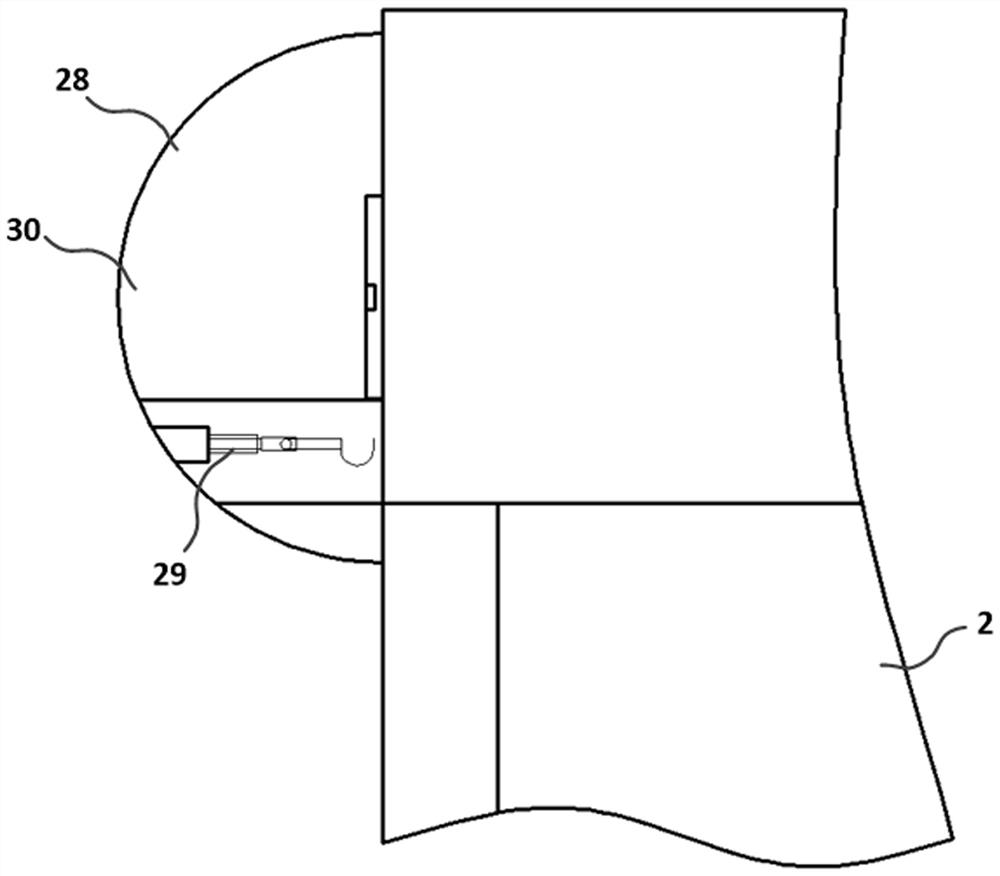

[0129] Such as Figure 1-9 As shown, in this embodiment, the driving device 24 drives the hydraulic lift 7 to rise to a position flush with the conveying device 4 and also includes:

[0130] The processor 23 outputs a sampling signal to the driving device 24 , and the sampling arm 29 acquires a soil sample from the soil unloading plate 9 and transfers it to the inspection chamber 30 .

[0131] The soil detection device 28 detects the components of the soil sample in the test chamber 30 and sends the detection data to the processor 23 .

[0132] The processor 23 analyzes the variety and growth state of the preset crops according to the captured image, and analyzes the required nutrients corresponding to the variety and the growth state.

[0133] The processor 23 judges whether the soil meets the required nutrients according to the detection data.

[0134] If not, the processor 23 extracts the missing element in the soil, and extracts the fertilizer containing the element in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com