Bentonite processing technology

A processing technology, bentonite technology, applied in the direction of separating solids from solids with airflow, silicon compounds, grain processing, etc., can solve the problems of waste and reduce the output of bentonite, so as to avoid waste, improve the crushing effect, increase yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

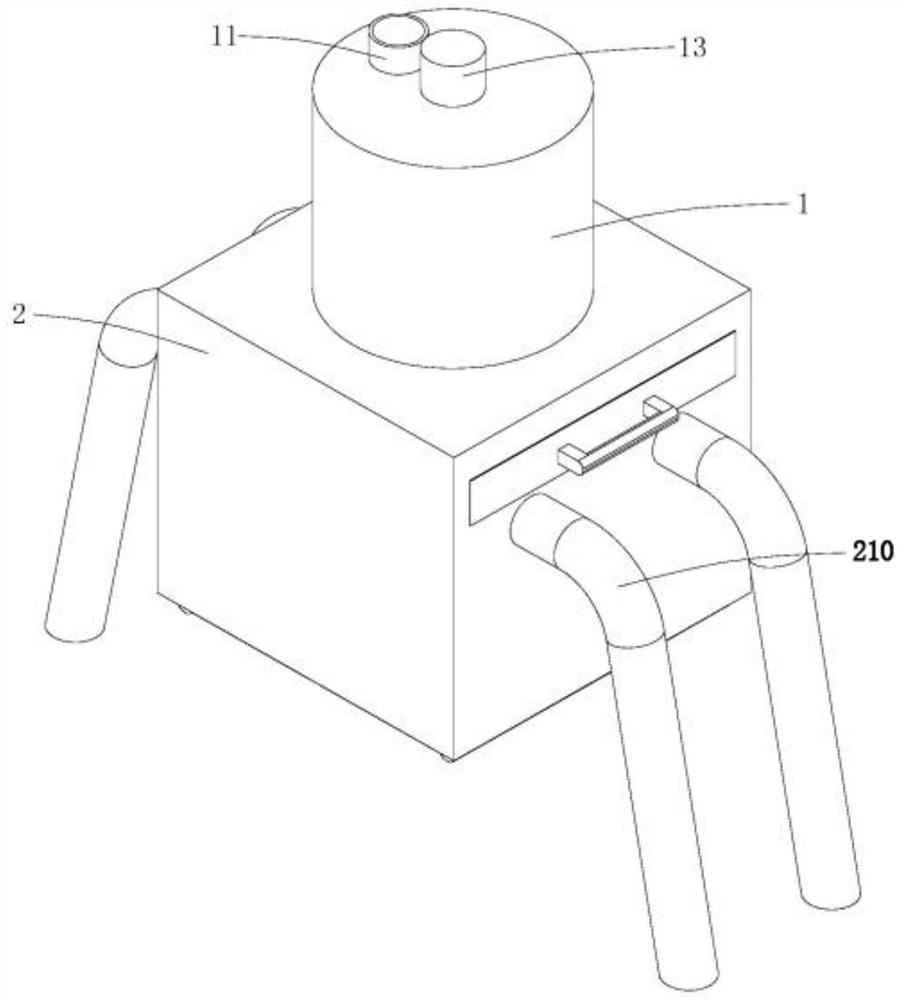

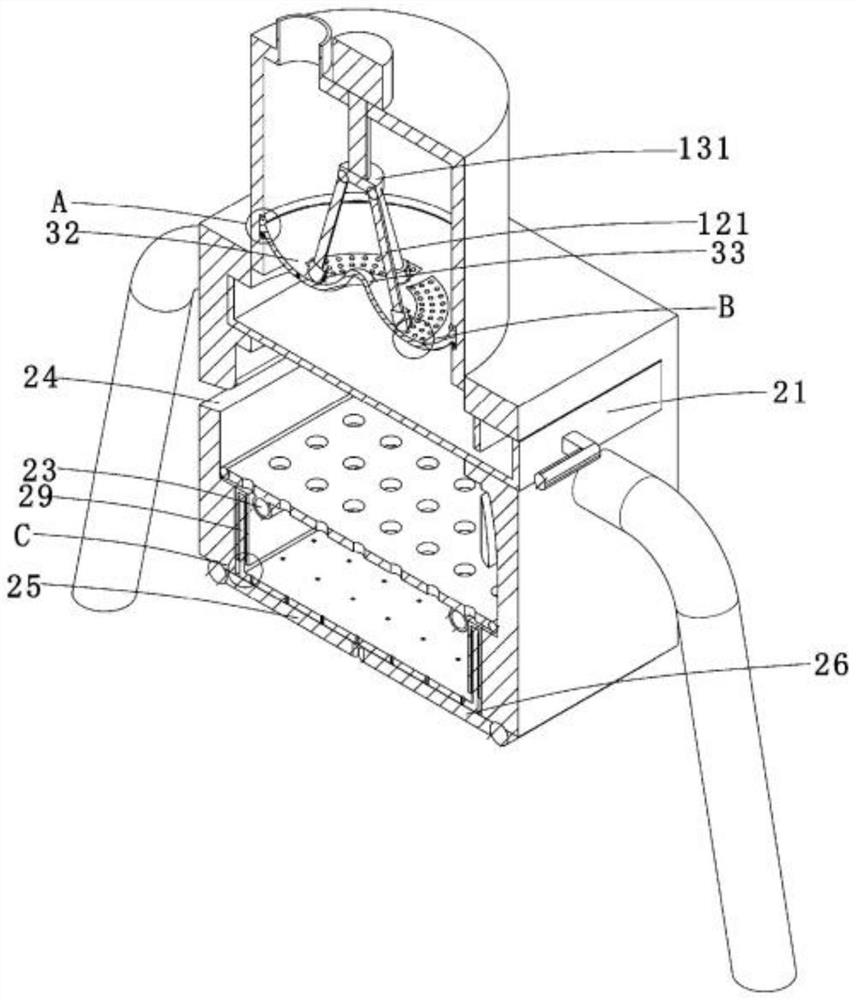

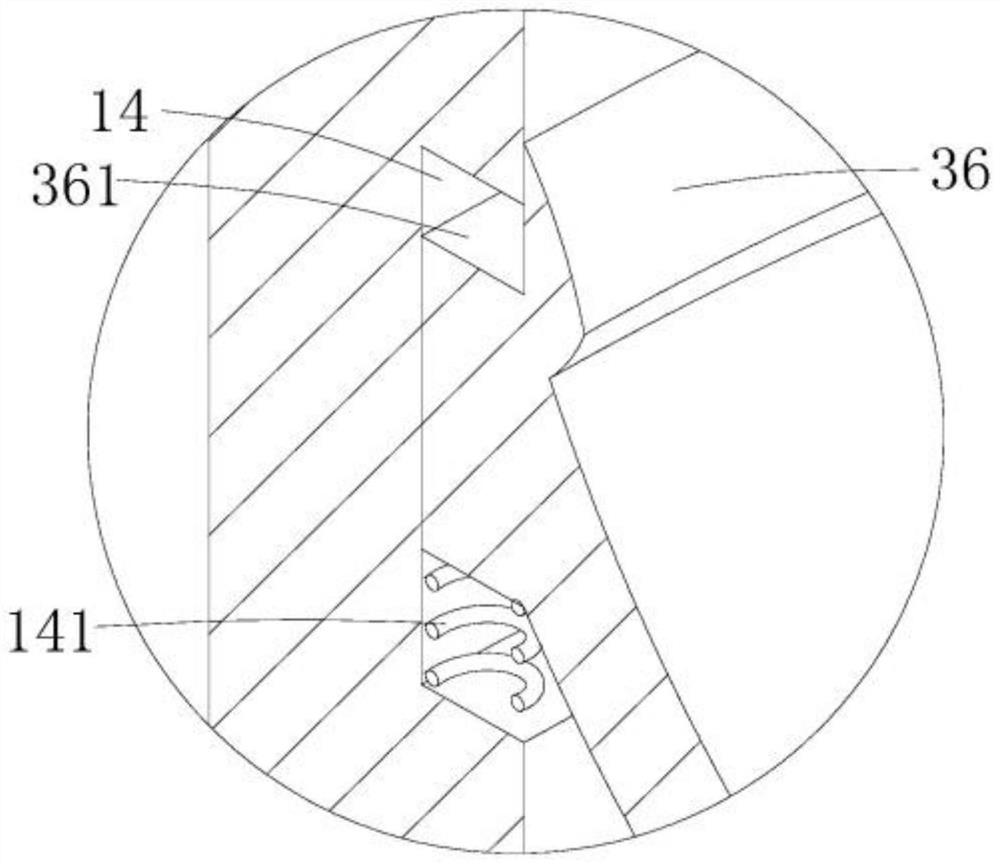

[0034] A bentonite processing technology, comprising the following steps: a. mineral processing: select high-quality bentonite ore to collect for use; b. raw material testing: after obtaining bentonite raw ore, carry out preliminary testing to it; c. d. Ore crushing: use bentonite crushing equipment to break bentonite raw materials into small pieces and remove sand and stones; e. drying: dry bentonite raw materials in natural sunlight; f. Grinding: drying After the bentonite is ground to the specified fineness; g. packaging and storage: pack the bentonite raw material after grinding; when the bentonite in the step a is selected, it is necessary to pay attention to the color, grade, and Aspects such as composition, ion exchange capacity, colloid performance, adsorption performance vary in thousands ways, and the quality of the bentonite product produced by it is also quite different; When the bentonite raw ore in the described step b is assayed, mainly to the montmorillonite in ...

Embodiment 2

[0043] A bentonite processing technology, comprising the following steps: a. mineral processing: select high-quality bentonite ore to collect for use; b. raw material testing: after obtaining bentonite raw ore, carry out preliminary testing to it; c. d. Ore crushing: use bentonite crushing equipment to break bentonite raw materials into small pieces and remove sand and stones; e. drying: dry bentonite raw materials in natural sunlight; f. Grinding: drying After the bentonite is ground to the specified fineness; g. packaging and storage: pack the bentonite raw material after grinding; when the bentonite in the step a is selected, it is necessary to pay attention to the color, grade, and Aspects such as composition, ion exchange capacity, colloid performance, adsorption performance vary in thousands ways, and the quality of the bentonite product produced by it is also quite different; When the bentonite raw ore in the described step b is assayed, mainly to the montmorillonite in ...

Embodiment 3

[0046]A bentonite processing technology, comprising the following steps: a. Mineral dressing: collect high-quality bentonite ore for use; b. Raw material testing: after obtaining bentonite raw ore, conduct a preliminary test on it; c. d. Ore crushing: use bentonite crushing equipment to break bentonite raw materials into small pieces and remove sand and stones; e. drying: dry bentonite raw materials in natural sunlight; f. Grinding: drying After the bentonite is ground to the specified fineness; g. packaging and storage: pack the bentonite raw material after grinding; when the bentonite in the step a is selected, it is necessary to pay attention to the color, grade, and Aspects such as composition, ion exchange capacity, colloid performance, adsorption performance vary in thousands ways, and the quality of the bentonite product produced by it is also quite different; When the bentonite raw ore in the described step b is assayed, mainly to the montmorillonite in the bentonite ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com