Train coaling carriage freeze-proof powder spraying equipment and spraying method thereof

A dry powder and coal charging technology, which is applied in the directions of loading/unloading, transportation and packaging, and conveying bulk materials, can solve the problems of belt conveyor equipment occupying a large area, the effect of dry powder spreading is not optimistic, and the effect of anti-freeze-dried powder is reduced. Conducive to environmental protection, easy to transport and spray, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

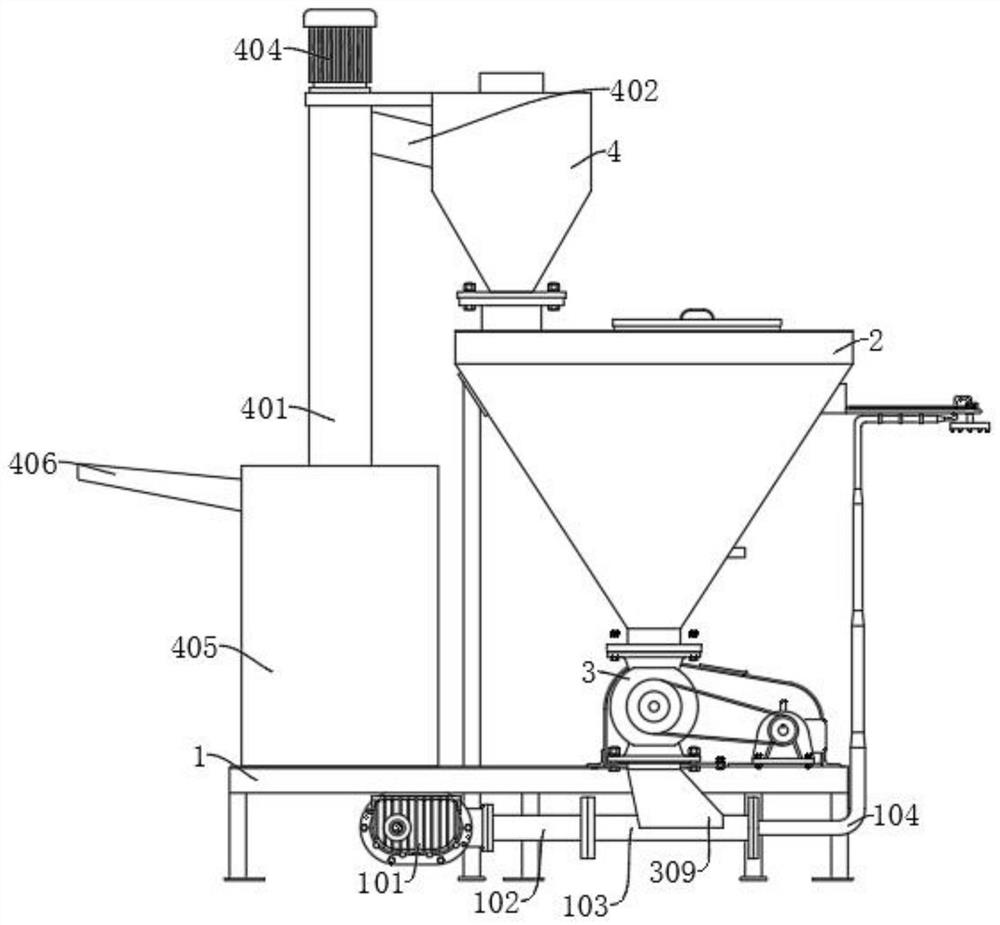

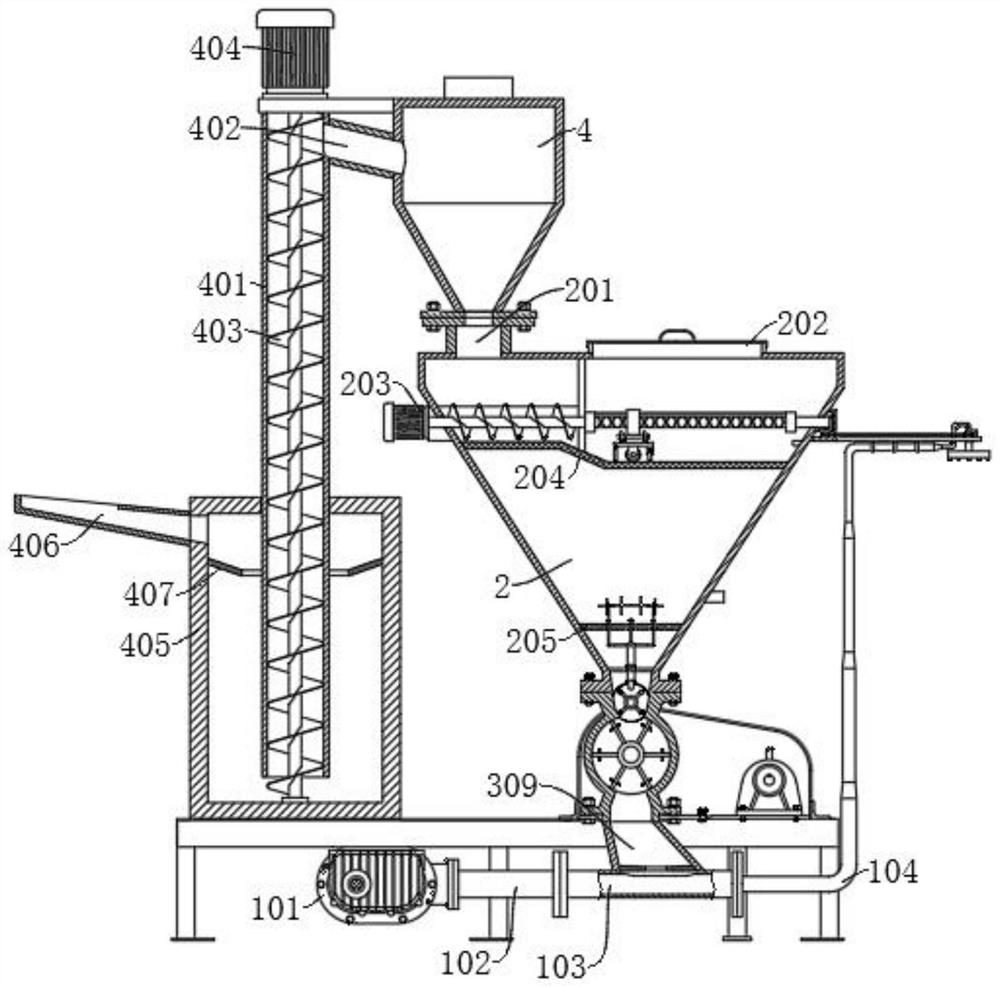

[0040] refer to Figure 1-11 , a kind of antifreeze-dried powder spraying equipment for train coaling carriages, comprising a support 1 and a Roots blower 101 arranged on the support 1, a feeder 3 is also provided on the support 1, and the top of the feeder 3 is provided with a The silo 2, when used, the dry powder will enter the silo 2, and then it can be evenly dropped by the feeder 3; the bottom of the feeder 3 is provided with a second connecting pipe 103, and the output end of the Roots blower 101 is provided with a The first connecting pipe 102 connected to the second connecting pipe 103, the end of the second connecting pipe 103 away from the first connecting pipe 102 is connected with the rotating disk 805 through the delivery pipe 104, and the Roots blower 101 is started, and the dry powder falling from the feeder 3 The material will enter the second connecting pipe 103, and then the Roots blower 101 starts blowing, and blows the dry powder material in the second conn...

Embodiment 2

[0044] refer to figure 1 , figure 2 and Figure 7 , a kind of anti-freeze-dried powder spraying equipment in the coal-loading compartment of a train, which is basically the same as that of Embodiment 1, furthermore, a material bucket 405 is provided on the support 1, and a cylinder 401 is connected to the material bucket 405, and the bottom of the cylinder 401 is placed on the material The bottom of the barrel 405, and the cylinder 401 is provided with a screw feeder 403, the outer wall of the barrel 405 is provided with a feed hopper 406, and the barrel 405 is provided with an annular sloping plate 407, and the annular sloping plate 407 can make the material enter the barrel. The material in the 405 can be piled up in the middle of the bottom of the bucket 405, so that the screw feeder 403 is convenient for feeding.

[0045] The top of the silo 2 is connected to the collector 4 through the connecting flange 201, and an inclined pipe 402 is arranged obliquely between the co...

Embodiment 3

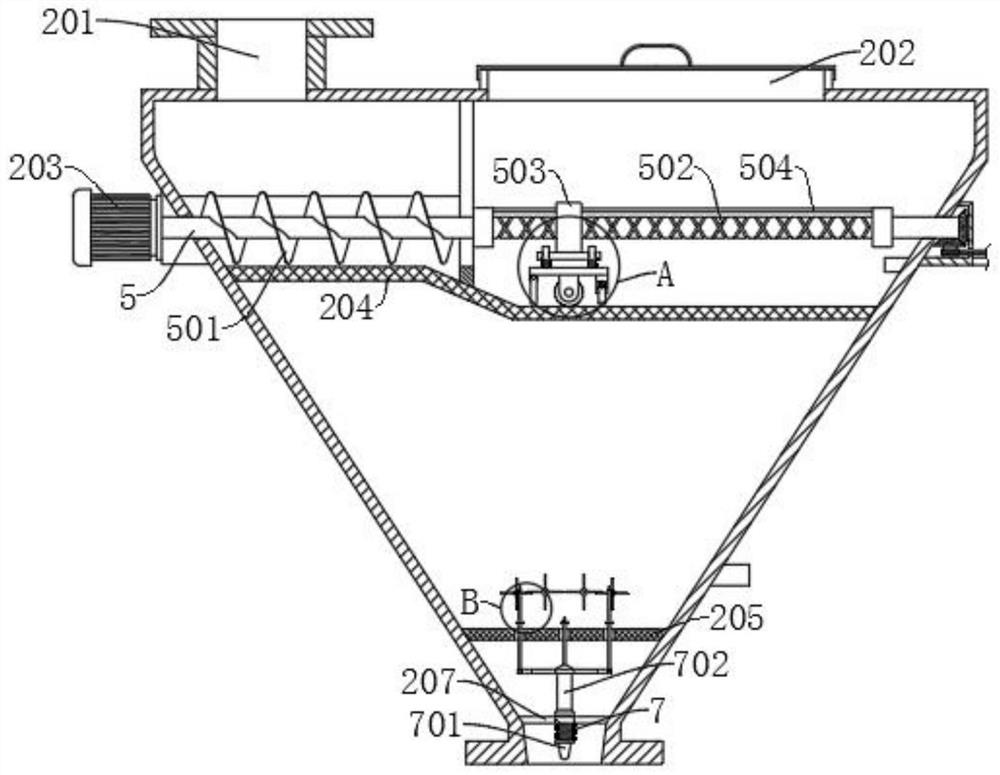

[0048] refer to Figure 1-5 and Figure 9 , a kind of anti-freeze dry powder spraying equipment in the coal-loading compartment of a train, the bottom of the feeder 3 is provided with a second connecting pipe 103, the output end of the Roots blower 101 is provided with a first connecting pipe 102 connected to the second connecting pipe 103, the second The end of the second connecting pipe 103 away from the first connecting pipe 102 is connected with a rotating disk 805 through the delivery pipe 104, and the rotating disk 805 is connected with a hollow shaft 804 through a support rod 806, and the bottom of the rotating disk 805 and the supporting rod 806 is provided with a dry powder spray nozzle 807 , the bottom of the feeder 3 is provided with a feeding chamber 308 that communicates with the second connecting pipe 103; a filter screen 204 is provided in the feed bin 2, and a rolling roller 5014 is reciprocated on the screen screen 204, and the bottom of the feed bin 2 A filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com