A Friction Stir Welding Method of Silicon Carbide Particles Reinforced Aluminum Matrix Composite

A silicon carbide particle and friction stir welding technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of particle segregation in the strengthening phase, low service life of stirring tools, and excessive heat input, etc., to improve the use of life, reduction of harmful metallurgical reactions, and increased welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

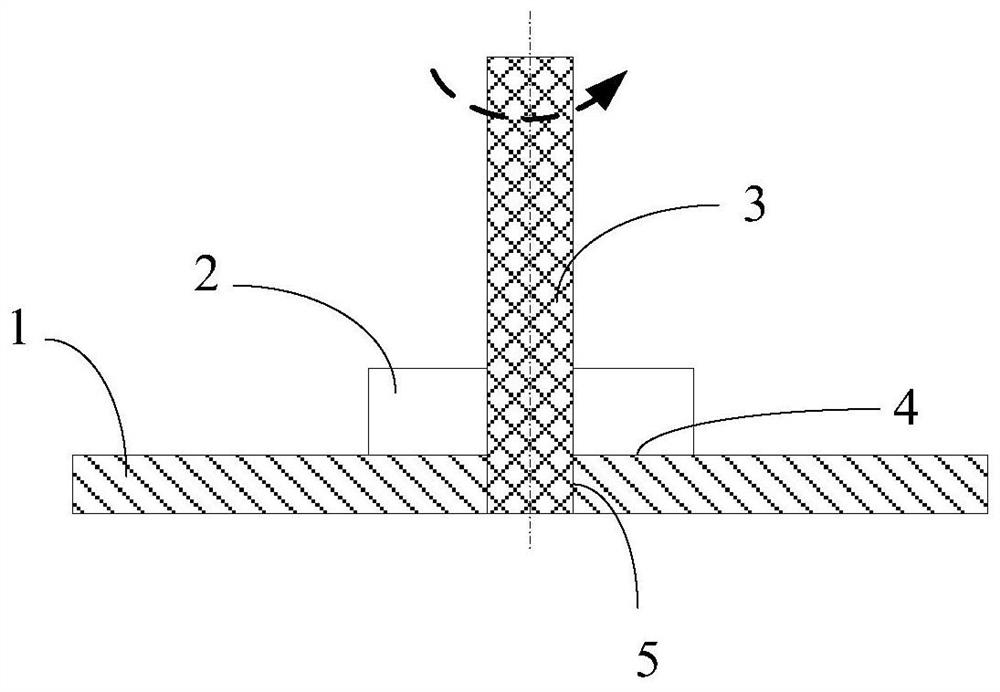

[0016] see figure 1 , the friction stir welding method of silicon carbide particle reinforced aluminum matrix composite material of the present invention comprises the following steps:

[0017] S1, the stirring pin 3 is made of conventional tool steel, and a coating with high wear resistance and high friction coefficient is prepared on the surface 5 of the stirring pin;

[0018] S2, the shaft shoulder 2 is made of conventional tool steel, and a coating with high wear resistance and low friction coefficient is prepared on the end face 4 of the shaft shoulder;

[0019] S3. During the friction stir welding process of the stationary shoulder, the rotating stirring pin 3 is first inserted into the silicon carbide particle reinforced aluminum m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com