An Energy Saving Scheduling Control Method Considering Equipment Maintenance for Mixed Flow Workshop

A technology for equipment maintenance and scheduling control, applied in general control systems, program control, control/regulation systems, etc., can solve problems such as production delays, hidden safety hazards, energy consumption, etc., to improve computing speed and robustness, and prevent loss , the effect of expanding the sampling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

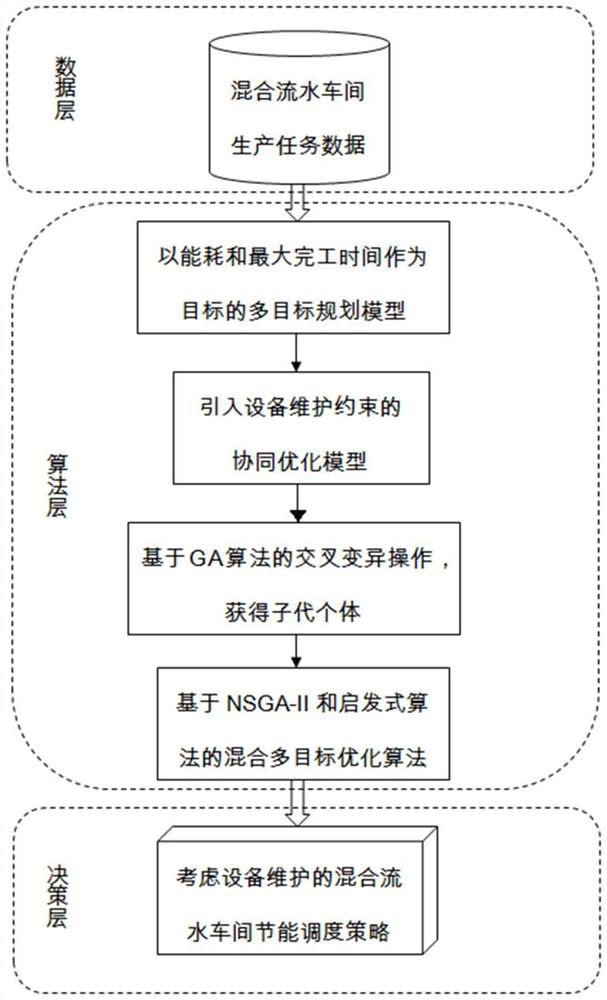

[0060] Such as figure 1 Shown is a flow chart of an energy-saving scheduling control method for a mixed flow workshop considering equipment maintenance according to the present invention. The method specifically includes the following steps:

[0061] Step 1: Obtain the production constraints and solve the objective function according to the production characteristics of the mixed flow workshop, and introduce the energy consumption target to establish a multi-objective programming model;

[0062] Step 2: Analyze the impact of equipment maintenance on production scheduling based on equipment maintenance data, and add equipment maintenance as corresponding constraints to the multi-objective programming model to form a complete multi-objective programming model;

[0063] Step 3: Use the GA (genetic) algorithm to perform coding genetic operations on the actual mixed flow workshop to obtain offspring individuals;

[0064] Step 4: Use NSGA-II (non-dominated sorting genetics with eli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com