Composite cavity sound baffle

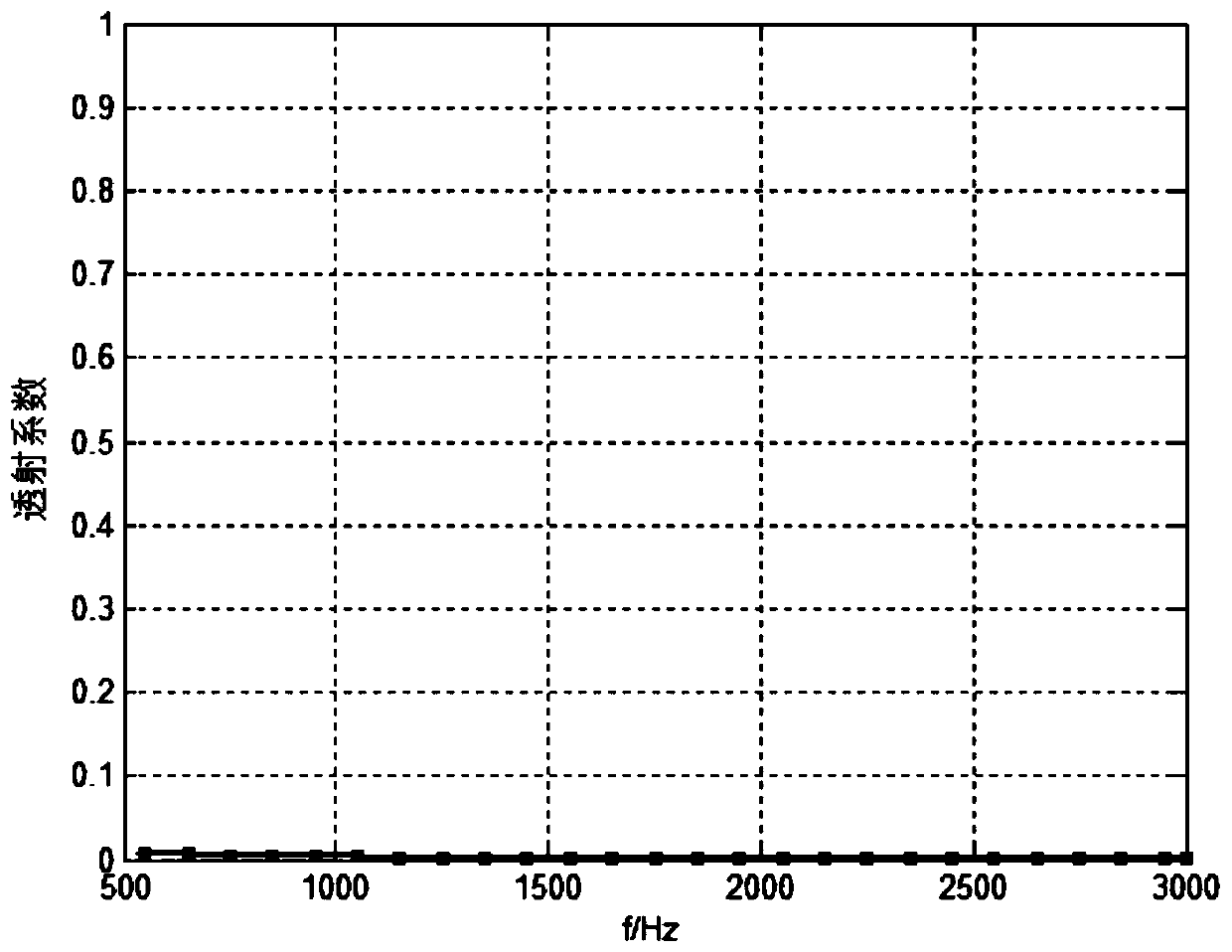

A technology of acoustic baffles and cavities, which is applied in the direction of sound-emitting devices and instruments, can solve the problems affecting the performance of the vector broadside array sonar system, the effective working frequency band of the vector sensor is narrow, and the range of reflection gain is large. Signal reception, simple structure, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples describe the present invention in more detail.

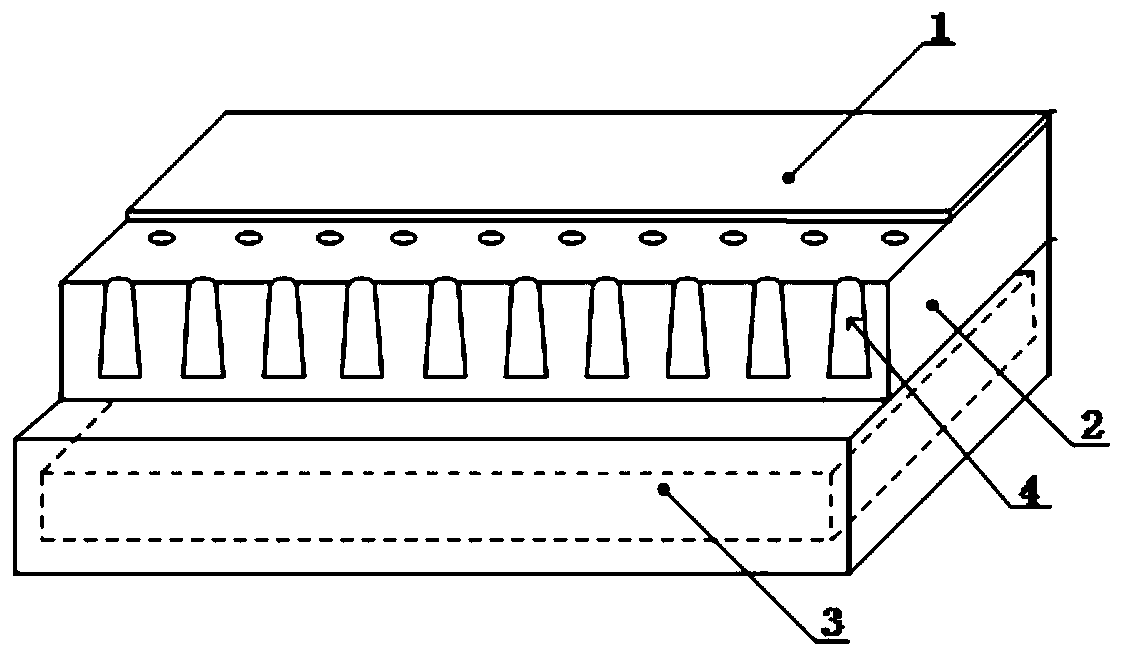

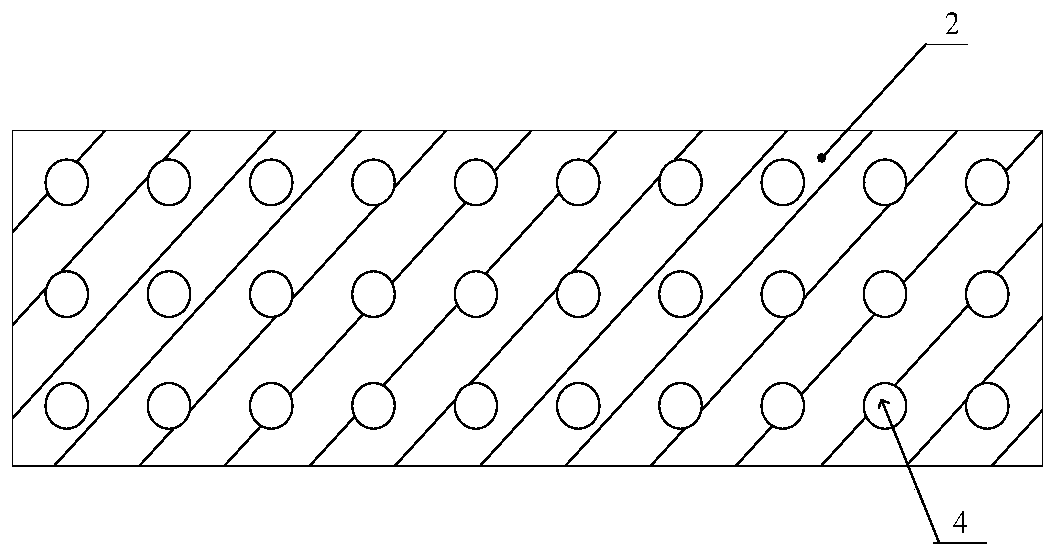

[0025] Combine figure 1 with figure 2 , A composite rectangular cavity baffle applied to a vector side array sonar system includes a sealing layer 1, a rubber cavity layer 2 and a cavity baffle 3 welded into an air cavity by a thin metal plate. The rubber The cavity layer is embedded with circular truncated cavities 4 arranged periodically, and the vector sensor is disposed at a certain distance above the sealing layer during application. Both the sealing layer and the rubber cavity layer are made of ethylene propylene rubber, and the cavity baffle plate welded into the air cavity by metal thin plates is made of steel material. The distance between the axes of all truncated cone cavities on the selected rubber cavity layer is 10mm, the height of the truncated cone cavity is 16mm, the diameter of the top surface of the truncated cone is 4.2mm, the diameter of the bottom surface of the truncated cone is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com