Maximizing steam methane reformer combustion efficiency by pre-heating pre-reformed fuel gas

一种预重整器、预重整的技术,应用在燃料、气体燃料、气体处理等方向,能够解决没有披露燃料气体预加热的方法、没有披露实现方式等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Although the present invention will be described in conjunction with several embodiments, it should be understood that it is not intended to limit the present invention to those embodiments. On the contrary, the intention is to cover all alternatives, modifications, and equivalents that can be included within the spirit and scope of the invention as defined by the appended claims.

[0040] There have been many efforts to improve the thermal efficiency of standard SMR. A pinch analysis shows that the standard SMR has been sufficiently thermally optimized, and therefore, further improvements related to heat exchanger design are unlikely to result in substantial improvements. However, embodiments of the present invention can advantageously improve the hitherto known methods by recovering waste heat more efficiently without attempting to re-optimize the process by overcoming the temperature pinch point.

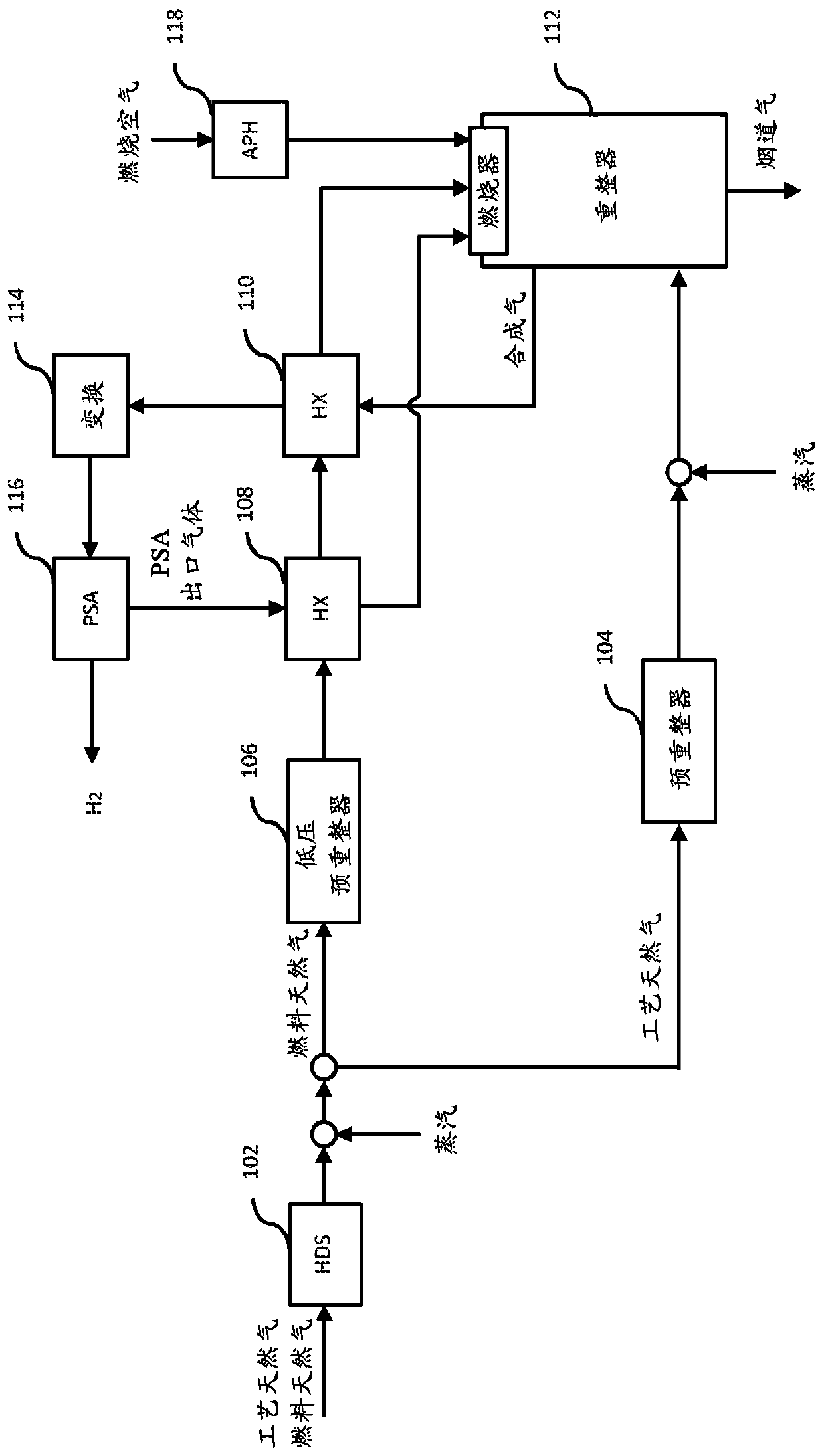

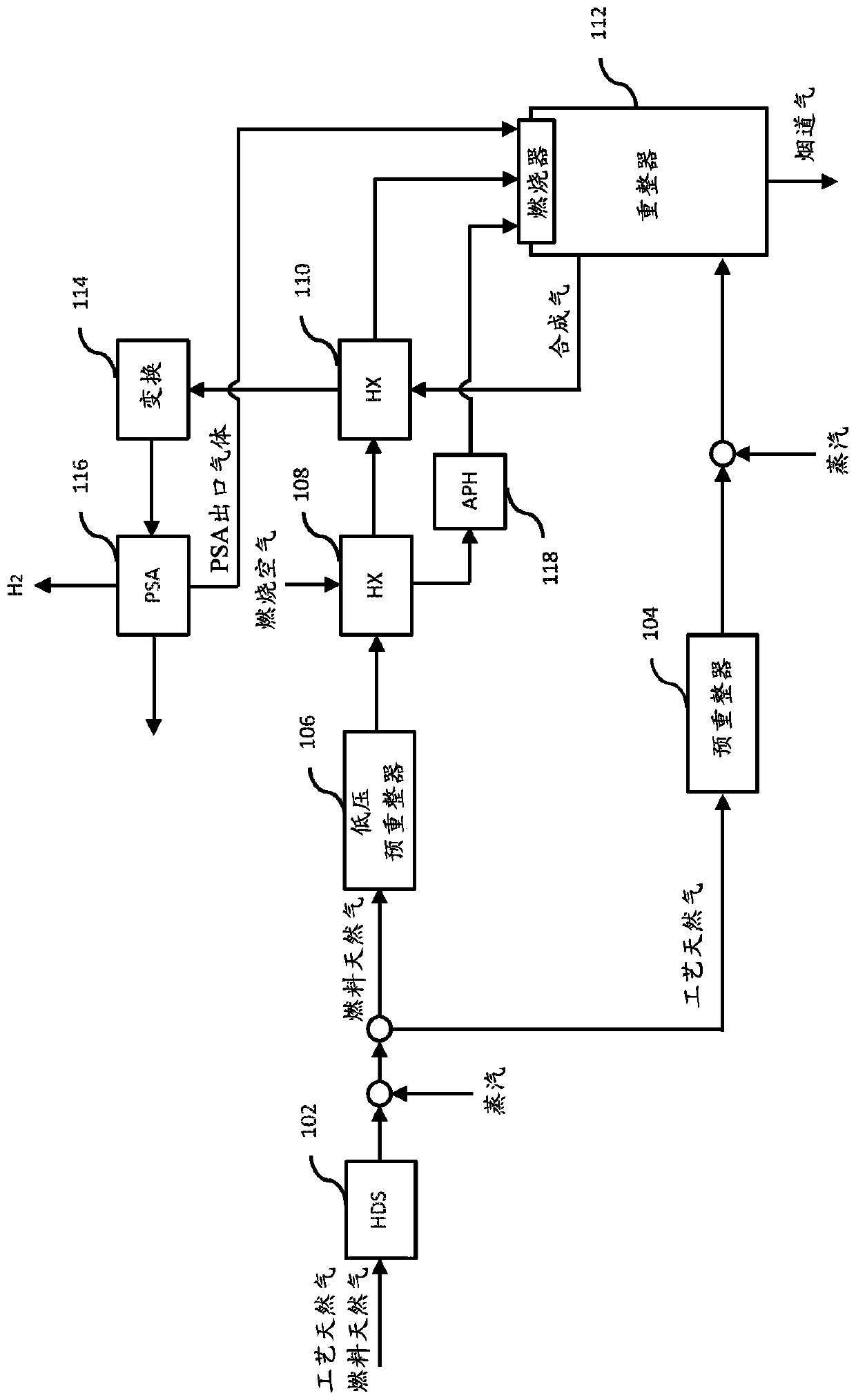

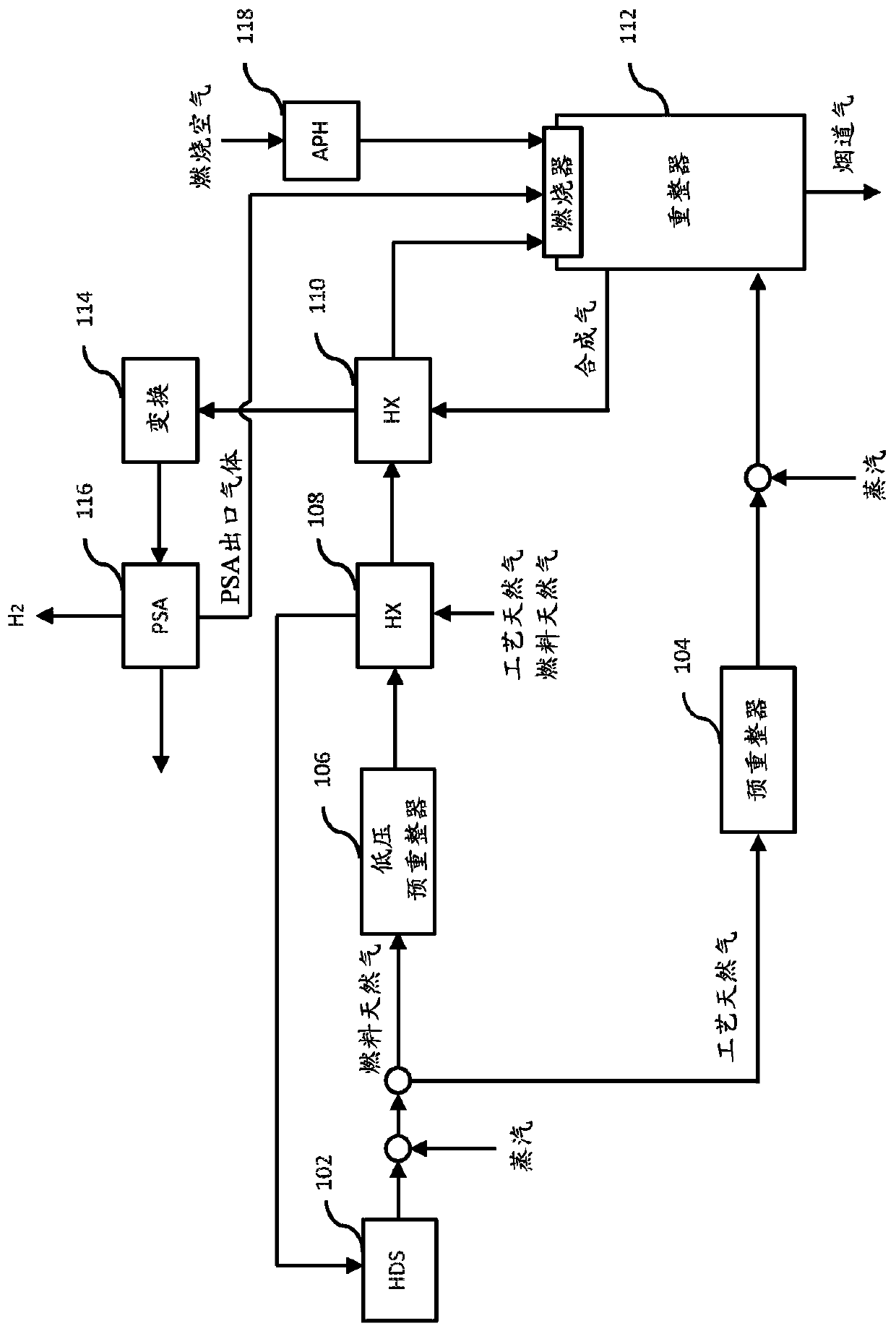

[0041] The disclosed embodiments provide a direct method that uses a low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com