A kind of calcium alginate composite filter membrane, its preparation method and application

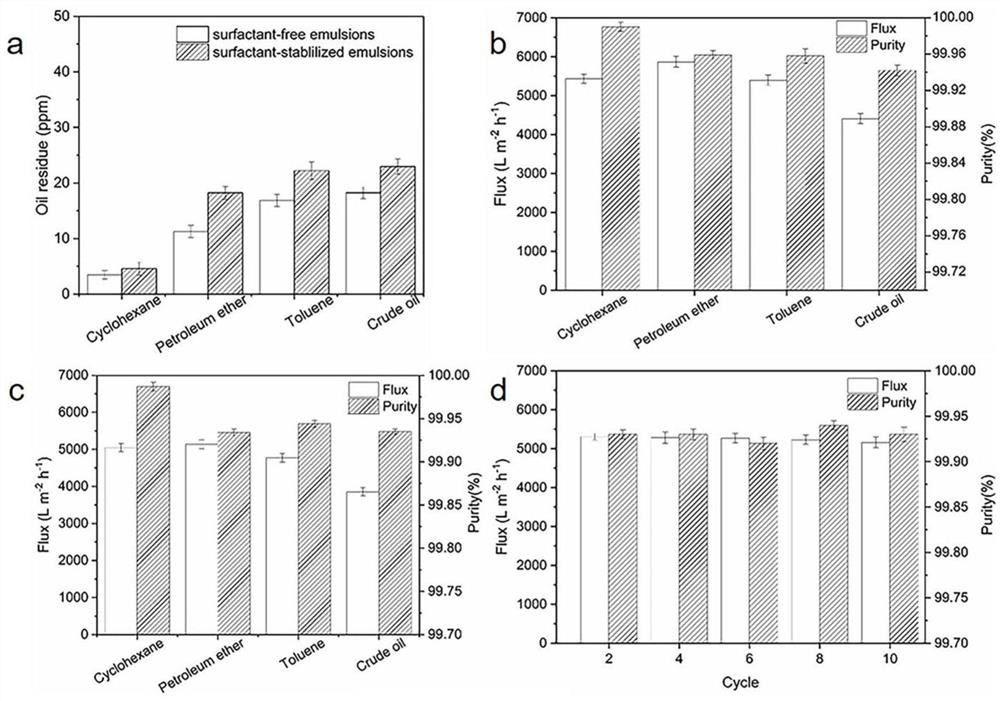

A technology of calcium alginate and sodium alginate, applied in the field of separation membranes, can solve the problems of high cost, secondary pollution of the environment, poor anti-fouling ability of the hydration layer, etc., and achieve the effect of strong anti-fouling ability and high water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

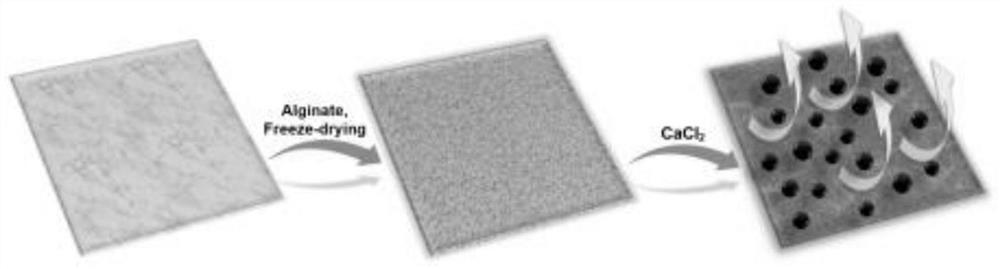

[0044] A preparation method for a calcium alginate composite filter membrane, comprising the following steps:

[0045] S1: Mix 0.05g of sodium alginate with 50ml of deionized water, stir for 0.5-1h, and let it stand for 12-24h to remove air bubbles to obtain a sodium alginate solution with a concentration of 0.1wt%.

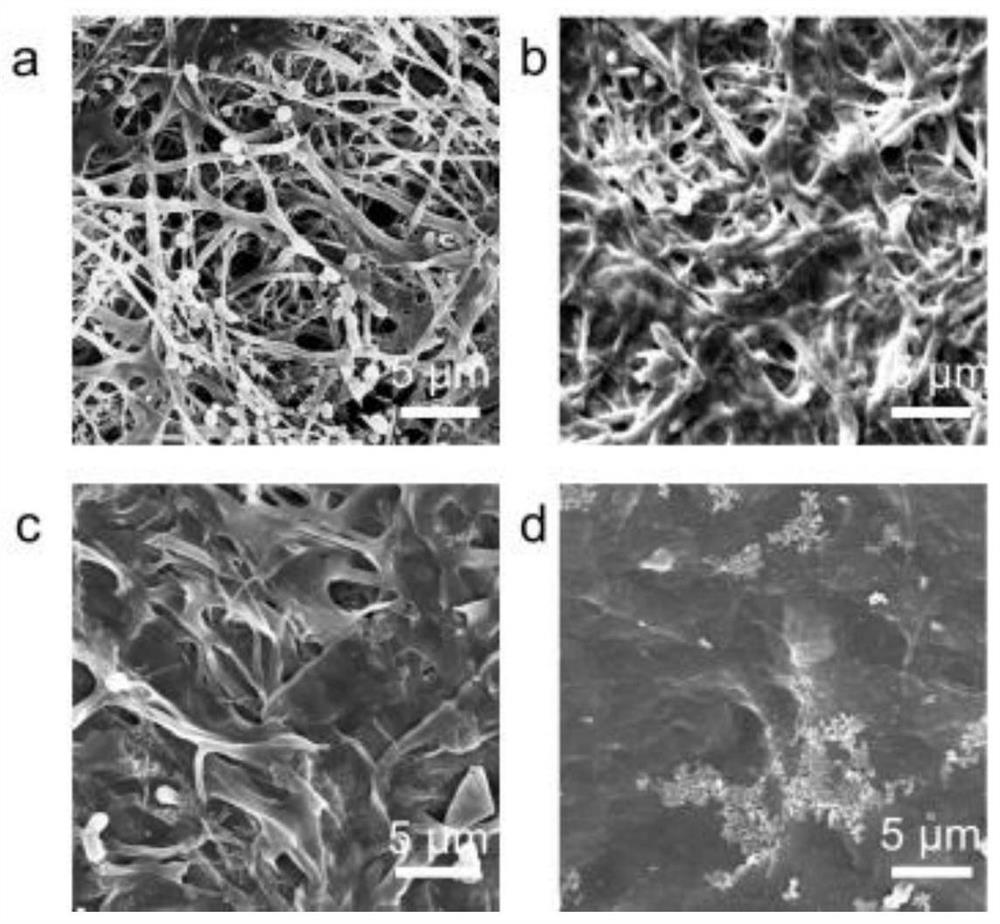

[0046] S2: Soak a square filter paper with a side length of 3cm in the sodium alginate solution for 4-5 hours, stir for 0.5-1 hour, and let it stand for 12-24 hours to remove air bubbles to obtain uniform sodium alginate filter paper. Place the sodium alginate filter paper on- Freeze-drying at 45°C for 24 hours to obtain a sodium alginate modified membrane;

[0047] S3: Mix anhydrous calcium chloride and deionized water according to the mass ratio of 1-10:20, and stir for 0.5-1 hour to obtain a calcium chloride solution;

[0048] S4: Soak the sodium alginate modified membrane in calcium chloride solution for 4-4.5 hours at 25-30° C., take it out and dry it for 1...

Embodiment 2

[0050] A preparation method for a calcium alginate composite filter membrane, comprising the following steps:

[0051] S1: Mix 0.075g of sodium alginate with 50ml of deionized water, stir for 0.5 to 1 hour, and let stand for 12 to 24 hours to remove air bubbles to obtain a sodium alginate solution with a concentration of 0.15wt%;

[0052] S2: Soak a square filter paper with a side length of 3cm in the sodium alginate solution for 4-5 hours, stir for 0.5-1 hour, and let it stand for 12-24 hours to remove air bubbles to obtain uniform sodium alginate filter paper. Place the sodium alginate filter paper on- 55 ℃ ~ 60 ℃, freeze-drying for 12 hours to obtain sodium alginate modified membrane;

[0053] S3: Mix anhydrous calcium chloride and deionized water according to the mass ratio of 1-10:20, and stir for 0.5-1 hour to obtain a calcium chloride solution;

[0054] S4: Soak the sodium alginate modified membrane in calcium chloride solution for 4-4.5 hours at 25-30° C., take it out...

Embodiment 3

[0056] A preparation method for a calcium alginate composite filter membrane, comprising the following steps:

[0057] S1: Mix 0.1g of sodium alginate with 50ml of deionized water, stir for 0.5-1h, let stand for 12-24h to remove air bubbles, and obtain a sodium alginate solution with a concentration of 0.2wt%;

[0058] S2: Soak a square filter paper with a side length of 3cm in the sodium alginate solution for 4-5 hours, stir for 0.5-1 hour, and let it stand for 12-24 hours to remove air bubbles to obtain uniform sodium alginate filter paper. Place the sodium alginate filter paper on- 30°C, freeze-drying for 10 hours to obtain sodium alginate modified membrane;

[0059] S3: Mix anhydrous calcium chloride and deionized water according to the mass ratio of 1-10:20, and stir for 0.5-1 hour to obtain a calcium chloride solution;

[0060] S4: Soak the sodium alginate modified membrane in calcium chloride solution for 4-4.5 hours at 25-30° C., take it out and dry it for 12-24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com