Biodegradable thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer, biodegradable technology, applied in the field of biodegradable thermoplastic elastomer materials and its preparation, can solve the problems of degradation performance degradation, poor elasticity, high hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

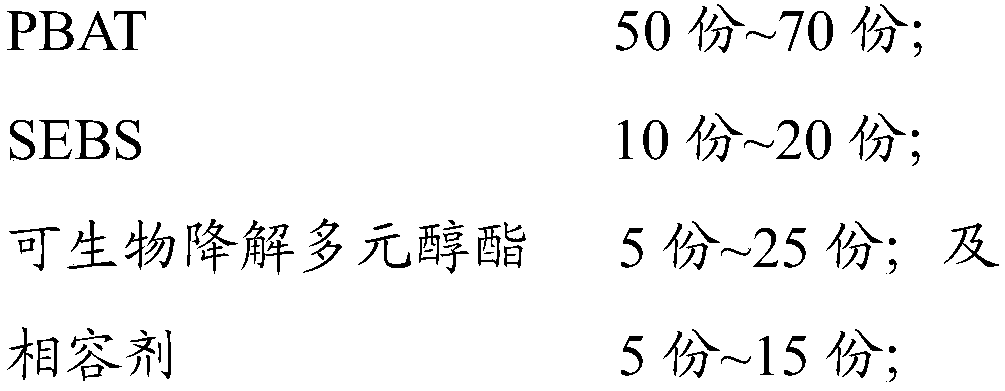

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned biodegradable thermoplastic elastomer material comprises the following steps:

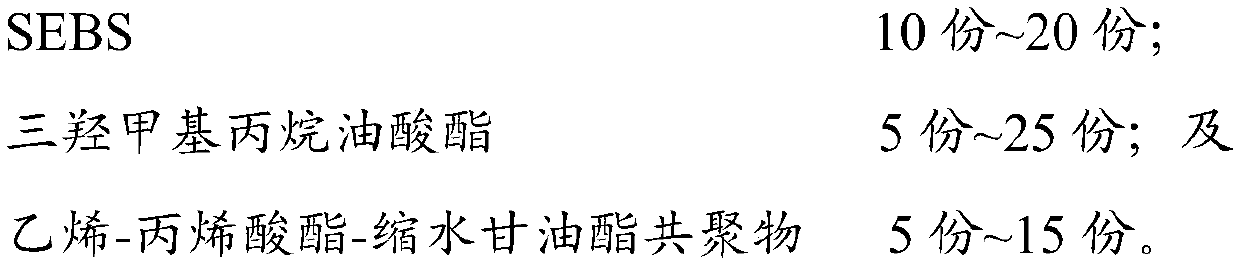

[0041] S110. In parts by mass, stir 10-20 parts of SEBS and 5-25 parts of biodegradable polyol ester until the SEBS fully absorbs the biodegradable polyol ester, and leave it for at least 3 days to obtain mixture.

[0042] Wherein, the biodegradable polyol ester is selected from at least one of trimethylolpropane oleate, trimethylolpropane caprylate, pentaerythritol oleate and isooctyl stearate.

[0043] In one of the embodiments, stirring is carried out in a stirrer, and the stirring rate is 85rpm~110rpm.

[0044] In one of the embodiments, stirring is performed for 5 minutes to 7 minutes.

[0045] In one of the embodiments, it is placed for 3 to 5 days.

[0046] S120. Stir and mix the mixture with 50-70 parts of PBAT and 5-15 parts of compatibilizer to obtain a premix evenly.

[0047] In one of the embodiments, stirring is carried out in a ...

Embodiment 1

[0061] 13 parts of SEBS (Kraton's G1651) and 5 parts of trimethylolpropane oleate were stirred for 6 minutes until SEBS fully absorbed the biodegradable polyol ester, and left for 3 days to obtain a mixture. The mixture was mixed with 70 parts of PBAT (BASF's FBlend C1200), 12 parts of maleic anhydride grafted SEBS and 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite were mixed and stirred for 5 minutes to obtain a premix.

[0062] Put the premix into the twin-screw extruder for plasticization, extrusion, vacuuming, cooling, granulation, and drying to obtain biodegradable thermoplastic elastomer materials. The temperature of the twin-screw extruder is 180 ° C ~ 200 ° C The rotation speed of the screw is 320rpm, and the length-to-diameter ratio of the screw is 45:1.

Embodiment 2

[0064] 10 parts of SEBS (Kraton's G1651) and 20 parts of trimethylolpropane oleate were stirred for 10 minutes until SEBS fully absorbed the biodegradable polyol ester, and left for 5 days to obtain a mixture. The mixture was mixed with 62 parts of PBAT (BASF's F BX7011), 8 parts of ethylene-acrylate-glycidyl ester copolymer and 0.1 part of tris(2,4-di-tert-butylphenyl) phosphite and 0.05 parts of β-(3,5-di-tert-butyl -4-Hydroxyphenyl)propanoic acid n-octadecyl ester was mixed and stirred for 5 minutes to obtain a premix.

[0065] Add the premix into the twin-screw extruder for plasticization, extrusion, vacuuming, cooling, granulation, and drying to obtain biodegradable thermoplastic elastomer materials. The temperature of the twin-screw extruder is 170°C to 190°C. The rotation speed of the screw is 300rpm, and the length-to-diameter ratio of the screw is 48:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com