Preparation of a self-sensing composite material adhesive and its self-monitoring method

A composite material and adhesive technology, which is used in the preparation of adhesives, test samples, material impedance, etc., can solve problems such as defects, expensive curing process, affecting the performance of final products, etc., to achieve high accuracy and achieve the effect of full life monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

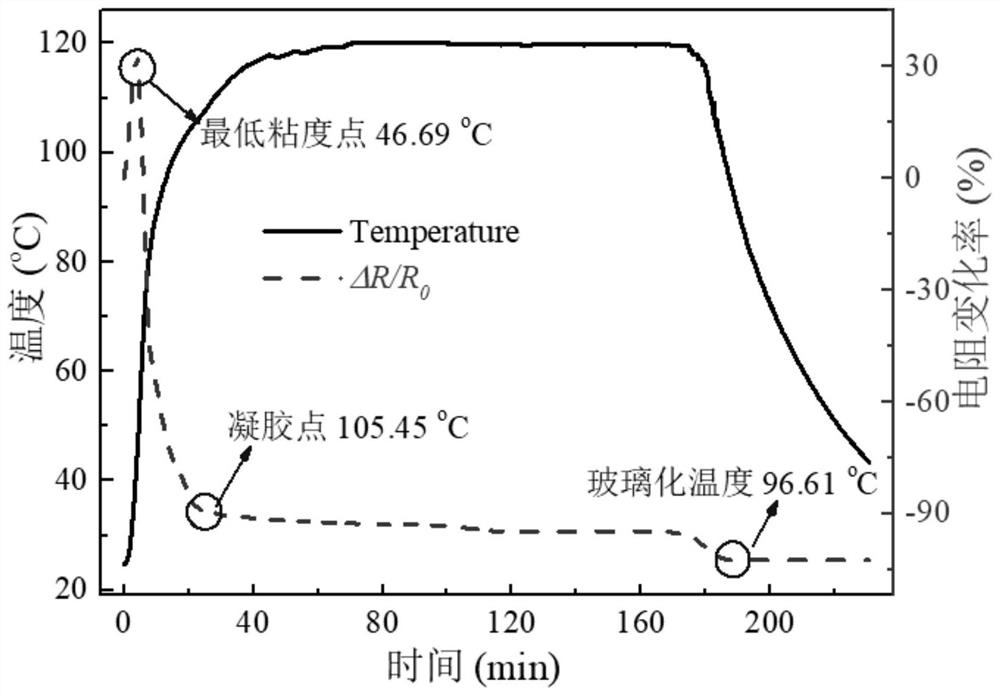

[0041] A preparation method of self-sensing composite material adhesive, comprising the following steps:

[0042] Step 1, graphene nanosheet solution preparation:

[0043] (1) Take the graphene intercalation compound and heat it at 700°C for 1.5min to obtain the graphene intercalation compound after thermal expansion;

[0044] (2) add acetone in the graphene intercalation compound after thermal expansion, the two proportioning is acetone: graphene intercalation compound=12:1 after thermal expansion, the unit is ml:g, mix homogeneously, form graphene acetone solution, to The graphene acetone solution is subjected to ultrasonication for 35 minutes, the ultrasonic power is 100W, and during the ultrasonication process, every ultrasonic 2-3s, pause for 1s, and the graphene nanosheet solution is obtained;

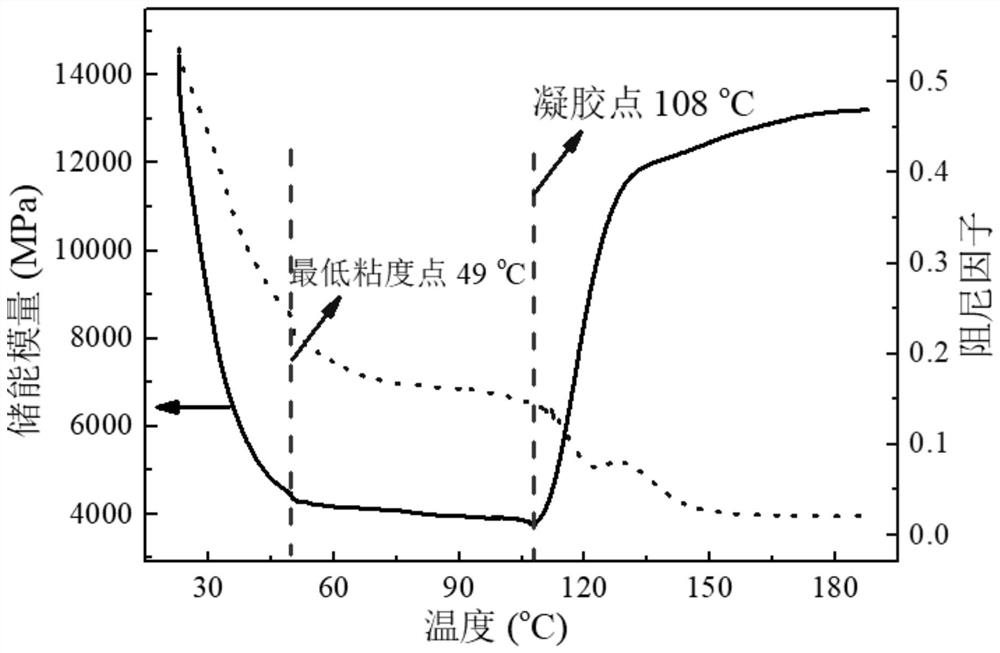

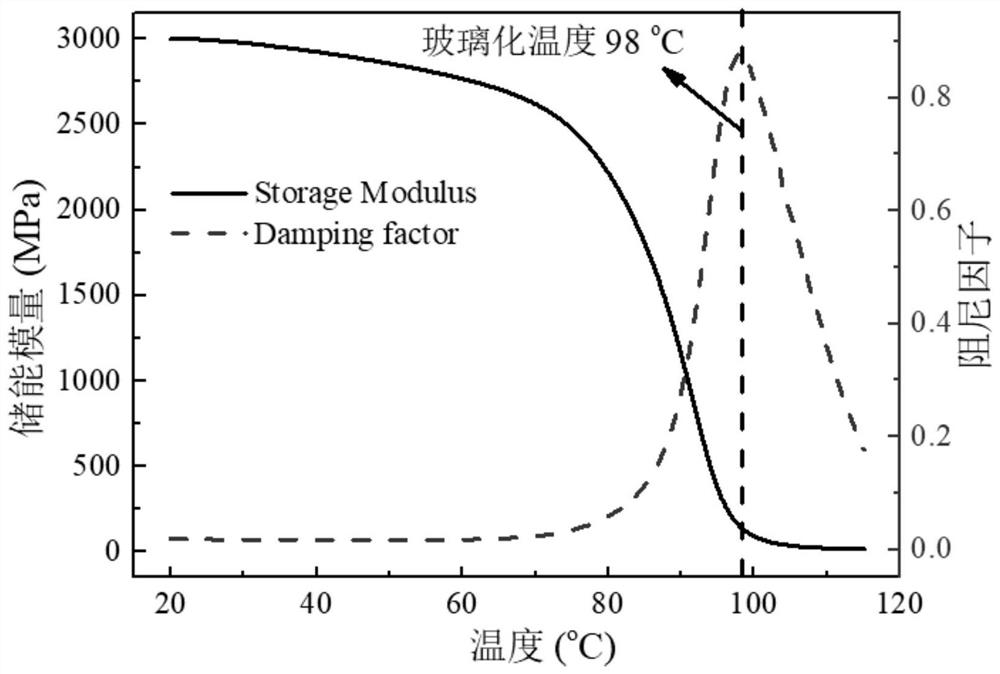

[0045] Step 2: Take epoxy resin, add acetone to dissolve completely, mix with graphene nanosheet solution, according to the mass ratio, epoxy resin: graphene = 1; 0.04, continue...

Embodiment 2

[0057] A preparation method of self-sensing composite material adhesive, comprising the following steps:

[0058] Step 1, graphene nanosheet solution preparation:

[0059] (1) Get the graphene intercalation compound and heat it at 650°C for 2min to obtain the graphene intercalation compound after thermal expansion;

[0060] (2) add acetone in the graphene intercalation compound after thermal expansion, the proportioning of the two is acetone: graphene intercalation compound=10:1 after thermal expansion, unit is ml:g, mix homogeneously, form graphene acetone solution, to The graphene acetone solution is subjected to ultrasonication for 50 minutes, the ultrasonic power is 90W, and during the ultrasonication process, every ultrasonic 2-3s, pause for 1s, and the graphene nanosheet solution is obtained;

[0061] Step 2: Take epoxy resin, add acetone to dissolve completely, and mix with graphene nanosheet solution. According to the mass ratio, epoxy resin: graphene = 1; 0.054, cont...

Embodiment 3

[0071] A preparation method of self-sensing composite material adhesive, comprising the following steps:

[0072] Step 1, graphene nanosheet solution preparation:

[0073] (1) Get the graphene intercalation compound and heat it at 800°C for 1min to obtain the graphene intercalation compound after thermal expansion;

[0074] (2) add acetone to the graphene intercalation compound after thermal expansion, the proportioning of the two is acetone: graphene intercalation compound=15:1 after thermal expansion, the unit is ml:g, mix uniformly, form graphene acetone solution, to The graphene acetone solution is subjected to ultrasonication for 20 minutes, the ultrasonic power is 110W, and during the ultrasonication process, every ultrasonic 2-3s, pause for 1s, and the graphene nanosheet solution is obtained;

[0075] Step 2: Take epoxy resin, add acetone to dissolve completely, mix with graphene nanosheet solution, according to the mass ratio, epoxy resin: graphene = 1; 0.046, continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com