Protein fiber reactive dye low-salt dyeing modification method

A protein fiber and reactive dye technology, applied in dyeing, fiber treatment, animal fiber, etc., can solve the problems of chemical residues, chemical reagents, environmental pollution, etc., achieve an increase in dyeing percentage, simple operation to control, and improve dyeing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

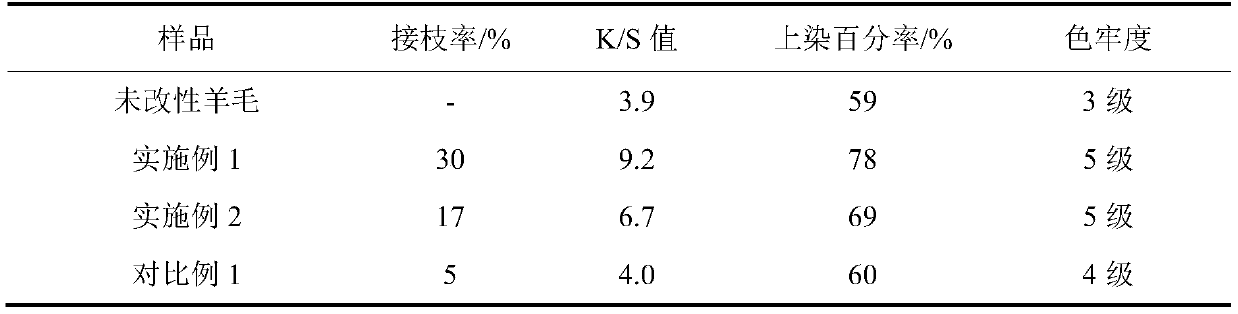

Embodiment 1

[0026] (1) Amination of wool: Weigh a certain amount of wool, immerse in a buffer solution of 4g / L chitosan oligosaccharide pH10, the bath ratio is 1:100, react at 90°C for 60 minutes, and use dinitro water to react the reaction solution The combination rate of chitosan and wool was determined to be 30% by citric acid chromogenic method, and the appearance color of wool did not change under this condition. After the wool is taken out, it is washed with water and dried to obtain aminated wool.

[0027] (2) Reactive dye dyeing of aminated wool: Take a certain amount of aminated wool and immerse it in a dye solution containing 3BSN reactive dye at 60°C with a concentration of 0.5% owf to start dyeing. After dyeing for 15 minutes, put 10g / L of chloride Sodium, continue dyeing at 60°C for 15 minutes, start to heat up, add 10g / L anhydrous sodium carbonate when it reaches 90°C, fix the color at 90°C for 30 minutes, and the dyeing is over. Take the wool out of the dyeing solution, wa...

Embodiment 2

[0029] (1) Amination of wool: Weigh a certain amount of wool, immerse in a buffer solution containing 2g / L chitosan oligosaccharide pH9, the bath ratio is 1:100, react at 80°C for 45 minutes, and use dinitro Salicylic acid chromogenic method determined that the binding rate of chitosan oligosaccharide and wool was 17%, and the appearance color of wool did not change under this condition. After the wool was taken out, it was washed with water and dried to obtain aminated wool.

[0030] (2) Reactive dye dyeing of aminated wool: Take a certain amount of aminated wool and immerse it in the dye solution containing Huasuhong 3BSN reactive dye at 60°C with a concentration of 0.3% owf to start dyeing. After dyeing for 15 minutes, put 10g / L chloride Sodium, continue dyeing at 60°C for 15 minutes, start to heat up, add 10g / L anhydrous sodium carbonate when it reaches 90°C, fix the color at 90°C for 30 minutes, and the dyeing is over. Take the wool out of the dyeing solution, wash off th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com