Wireless bar code logistics management system based on ORACLE-ERP integration, and management method thereof

A logistics management and line technology, applied in the direction of logistics, data processing applications, collaborative operation devices, etc., can solve the problems of low timeliness and accuracy of data entry, low degree of automation, inconsistent information flow, etc., to improve logistics efficiency, The effect of saving manpower and real-time barcode management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

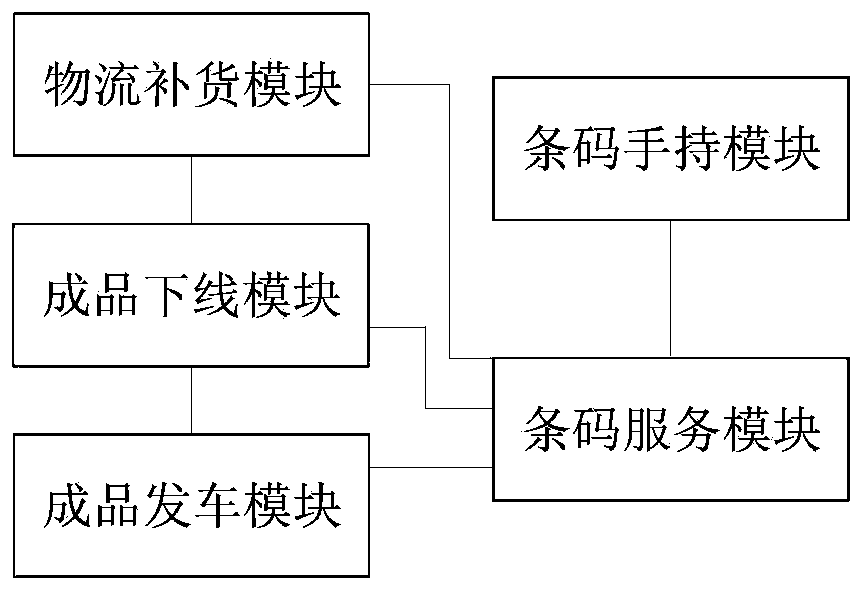

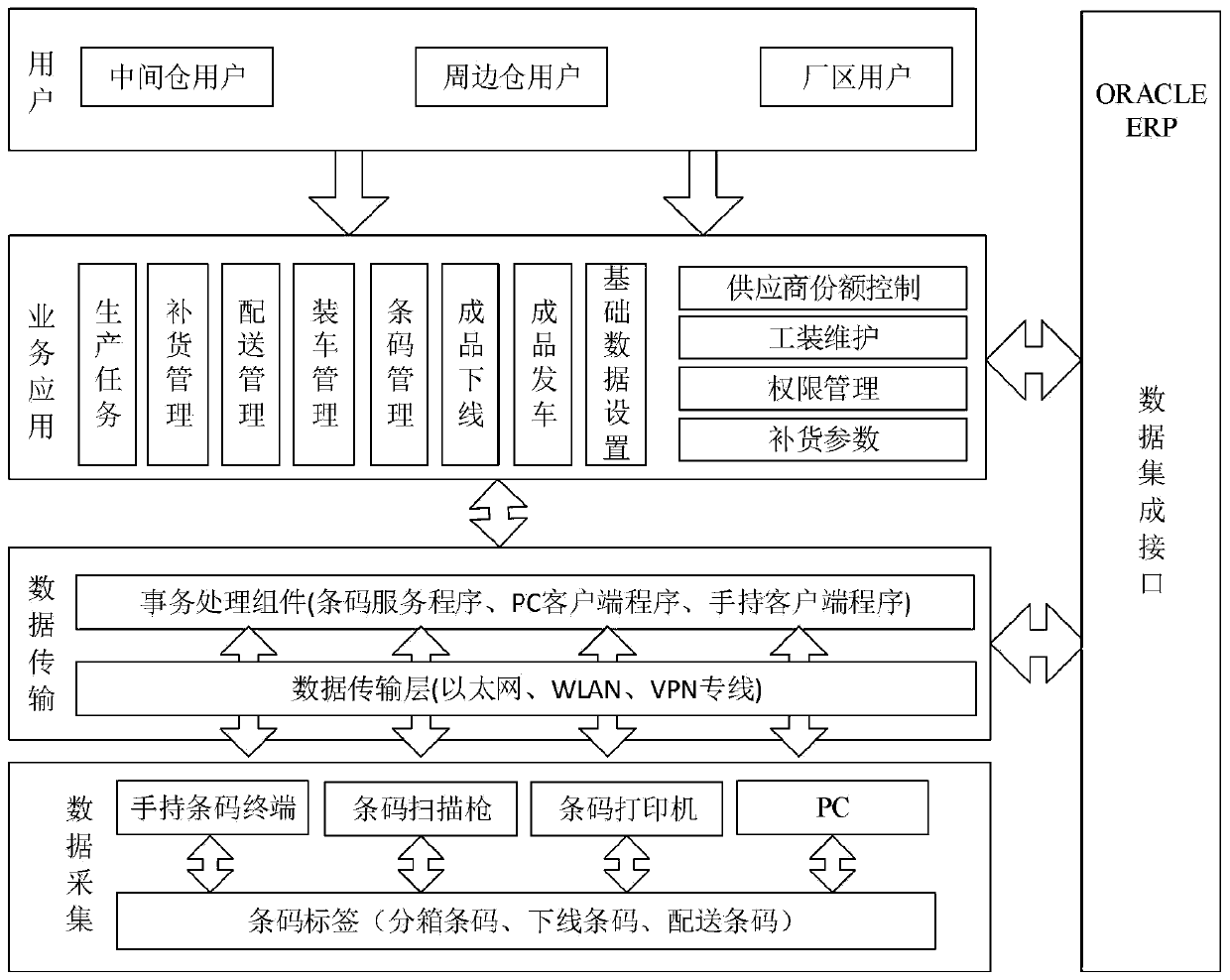

[0037] combine figure 1 Describe this embodiment, in this embodiment, a kind of wireless barcode logistics management system based on ORACLE-ERP integration involved in this embodiment, it comprises:

[0038] Logistics replenishment module: used to query the current inventory status, generate the corresponding replenishment order according to the set production tasks; generate the delivery order according to the set replenishment days; send the delivery order to the supplier; use the handheld PDA device to The loading list sent by the manufacturer is scanned, and the inventory data of the ORACLE-ERP system is updated in real time with the loading list information entered by the handheld PDA device;

[0039] Finished product off-line module: It is used to transmit the off-line code data of the finished product in the workshop collected by the handheld PDA device to the ORACLE-ERP system in real time to update the inventory data and automatically trigger the process movement;

...

Embodiment 2

[0044] This embodiment is described in conjunction with Embodiment 1. In this embodiment, a kind of wireless barcode logistics management system based on ORACLE-ERP integration involved in this embodiment, the logistics replenishment module also includes:

[0045] Inventory adjustment module: used to split the replenishment order for the production tasks within the specified number of days according to the space capacity limit and production beat in the factory area, as well as the set replenishment parameters; inventory minimization: according to the space capacity limit in the factory area and production tempo, reasonably set the replenishment system replenishment parameters, control the number of replenishment days, and only replenish the production tasks within the specified number of days. For example, if the replenishment days are set to 2, the system will automatically consider the production tasks within 2 days for replenishment The replenishment base is the quantity of...

Embodiment 3

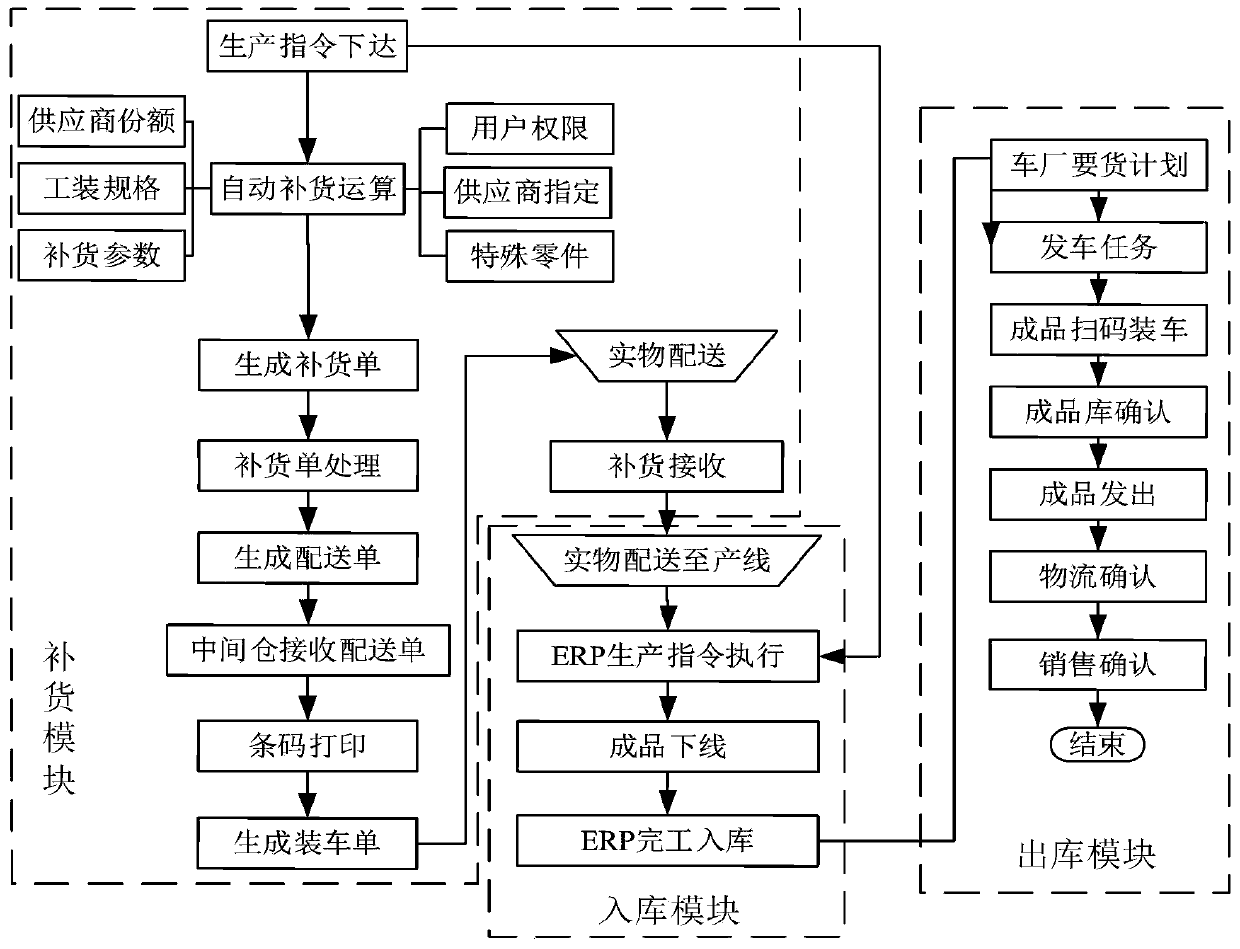

[0052] combine figure 2 Illustrate the present embodiment with embodiment 1, in the present embodiment, a kind of integrated wireless barcode logistics management system and its management method based on ORACLE-ERP involved in the present embodiment, it comprises the following steps:

[0053] Step 1. Generate a replenishment list: the ORACLE-ERP system queries the current inventory status, and reasonably sets replenishment parameters according to the space capacity limitation and production tempo in the factory area to split the production tasks as needed, for example, according to the standard parts replenishment list and Split the replenishment list for non-standard parts to generate the corresponding replenishment note;

[0054] Step 2: Generate delivery order: control the number of replenishment days, and only carry out replenishment for production tasks within the specified number of days, and the ORACLE-ERP system will disassemble the replenishment order into a deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com