Three-dimensional integrated structure for Micro LEDs and manufacturing method

A technology of three-dimensional integration and passivation layer, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of large area of metal rewiring layer, complex structure of metal rewiring layer, large area of MicroLED array, etc., and achieve reduction The effect of reducing the area, reducing the occupied area, and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] refer to Figure 1-Figure 4 , this embodiment provides a three-dimensional packaging method for Micro LEDs, including the following steps:

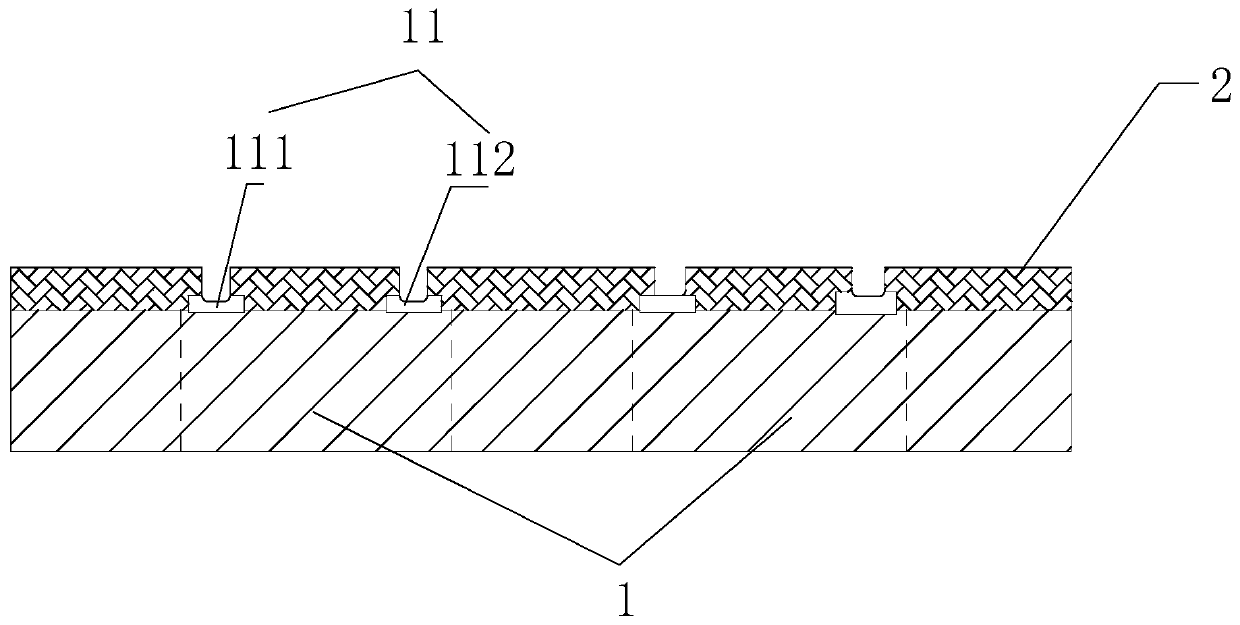

[0036] 1) Covering a layer of photoresist 2 on the Micro LED array 1 as the first insulating passivation layer;

[0037] 2) performing a photolithographic development process on the photoresist 2, opening holes in the photoresist 2 corresponding to the Micro LED pads 11, and exposing each of the Micro LED pads 11;

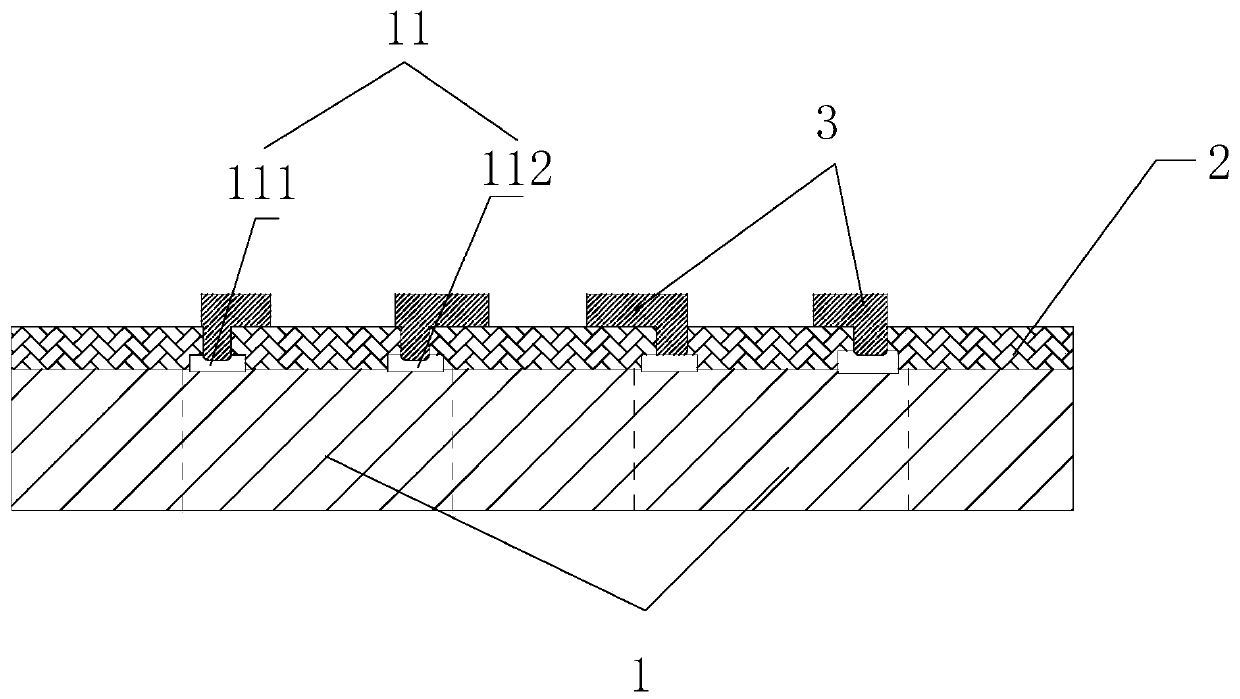

[0038] 3) Making the first metal wiring layer 3, the first metal wiring layer 3 is connected to the anode pad 111 of each of the Micro LEDs, and is also connected to the negative pad 112 of each of the Micro LEDs, and along the opening extending to the upper surface of the photoresist 2;

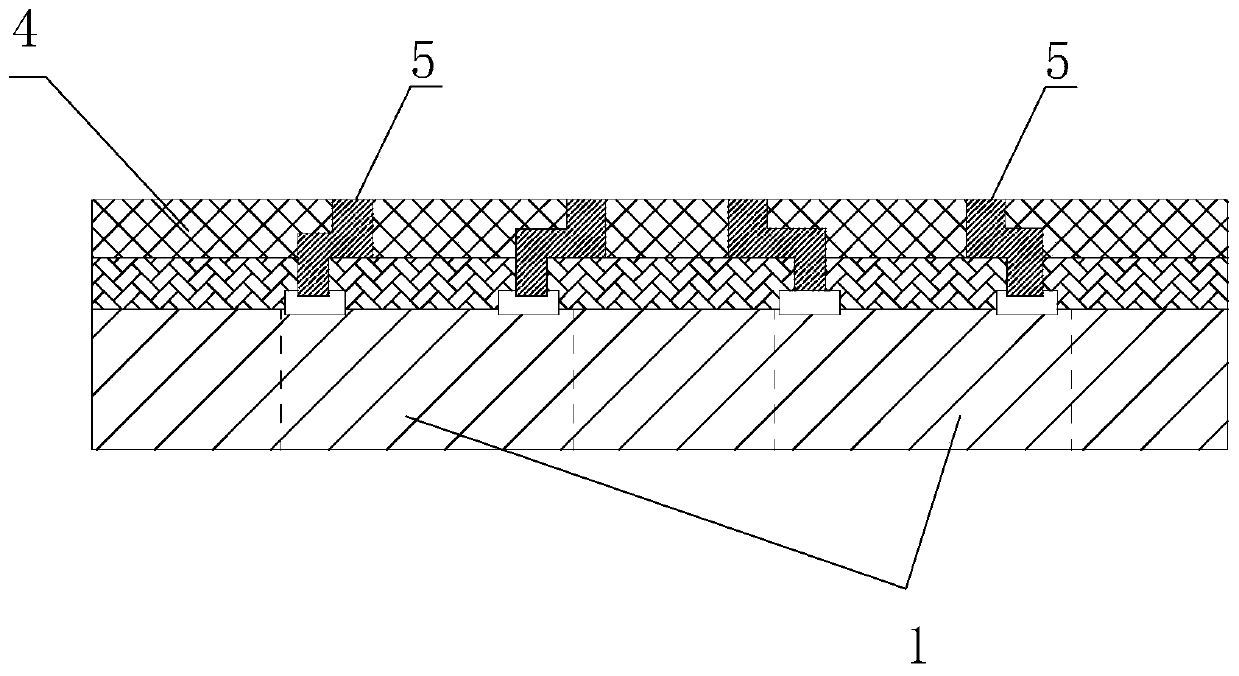

[0039] 4) Make a second insulating passivation layer 4 on the upper surface of the photoresist 2, cover the part of the first metal wiring layer 3 exposed on the upper surface of the photoresist 2, and expose the first metal wiring l...

Embodiment 2

[0054] refer to Image 6 The difference between this embodiment and Embodiment 1 is that: the first metal wiring layer 3 is divided into a first part 31 connected to the positive electrode pad 111 and a second part 32 connected to the negative electrode pad 112; the first part 31 and the second part The two parts 32 are detachable and located on the upper and lower horizontal planes. Since the first part 31 and the second part 32 have a height difference, the first part 31 and the second part 32 can overlap each other in the vertical direction to reuse the space and further reduce the area of the first metal wiring layer 3 .

[0055] In order to avoid the mutual influence between the first part 31 and the second part 32, in this embodiment, the upper surface of the second insulating passivation layer 4 is also provided with a third insulating passivation layer 7, and the first part 31 is located on the first insulating passivation layer 4. layer and the second insulating pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com