Acidic milk beverage added with okra polysaccharide and preparation method thereof

An acid milk and polysaccharide technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of weak stability and high viscosity of acidic milk beverages, and achieve refreshing taste, non-sticky, good stability and emulsification. , the effect of increasing nutritional function and emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The formula of the sour milk beverage that the present embodiment adds okra polysaccharide is (in 1kg): skimmed milk powder 22g, okra polysaccharide 4g, white granulated sugar 40g, high fructose syrup 30g, aspartame 0.2g, acesulfame K 0.2 g, sodium citrate 0.2g and rose powder essence 0.4g, deionized water 903g.

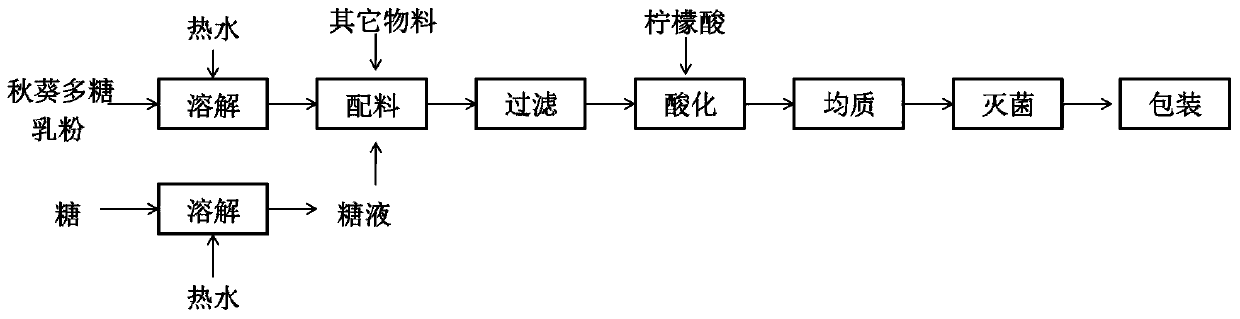

[0032] The preparation technology of present embodiment sour milk drink is as follows:

[0033] Step 1. After dry mixing 4g of okra polysaccharide and 22g of skim milk powder, dissolve it in 474g of deionized water at 60°C to obtain an emulsion; dissolve 40g of white sugar in 429g of deionized water at 55°C to obtain a sugar solution;

[0034] Step 2. Add the emulsion and sugar liquid into the batching tank and mix; then mix 0.2g aspartame, 0.2g acesulfame K, 0.2g sodium citrate and 0.4g edible flavor, and then add it to the batching tank; finally mix 30g Add high fructose syrup into the batching tank;

[0035] Step 3. Stir the mixed material in the batching...

Embodiment 2

[0040] The formula of the sour milk beverage that the present embodiment adds okra polysaccharide is (in 1kg): skimmed milk powder 24g, okra polysaccharide 6g, white granulated sugar 34g, high fructose syrup 35g, aspartame 0.2g, acesulfame K 0.2 g, sodium citrate 0.2g and orange essence 0.4g, water 900g.

[0041] The preparation technology of present embodiment sour milk drink is as follows:

[0042] Step 1. After dry mixing 6g of okra polysaccharide and 24g of skim milk powder, dissolve it in 470g of deionized water at 60°C to obtain an emulsion; dissolve 34g of white sugar in 430g of deionized water at 50°C to obtain a sugar solution;

[0043]Step 2, add the emulsion and sugar solution into the batching tank and mix; then mix 0.2g aspartame, 0.2g acesulfame potassium, 0.2g sodium citrate and 0.4g edible flavor, and then add it to the batching tank; finally mix 35g Add high fructose syrup into the batching tank;

[0044] Step 3. Stir the mixed material in the batching tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com