Negative pressure ink path system based on CAN-LIN protocol

A protocol and negative pressure technology, applied in the field of negative pressure ink system, can solve the problems of low reliability, high complexity and poor flexibility of the negative pressure ink system, and achieve high reliability, strong adaptability and low maintenance cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

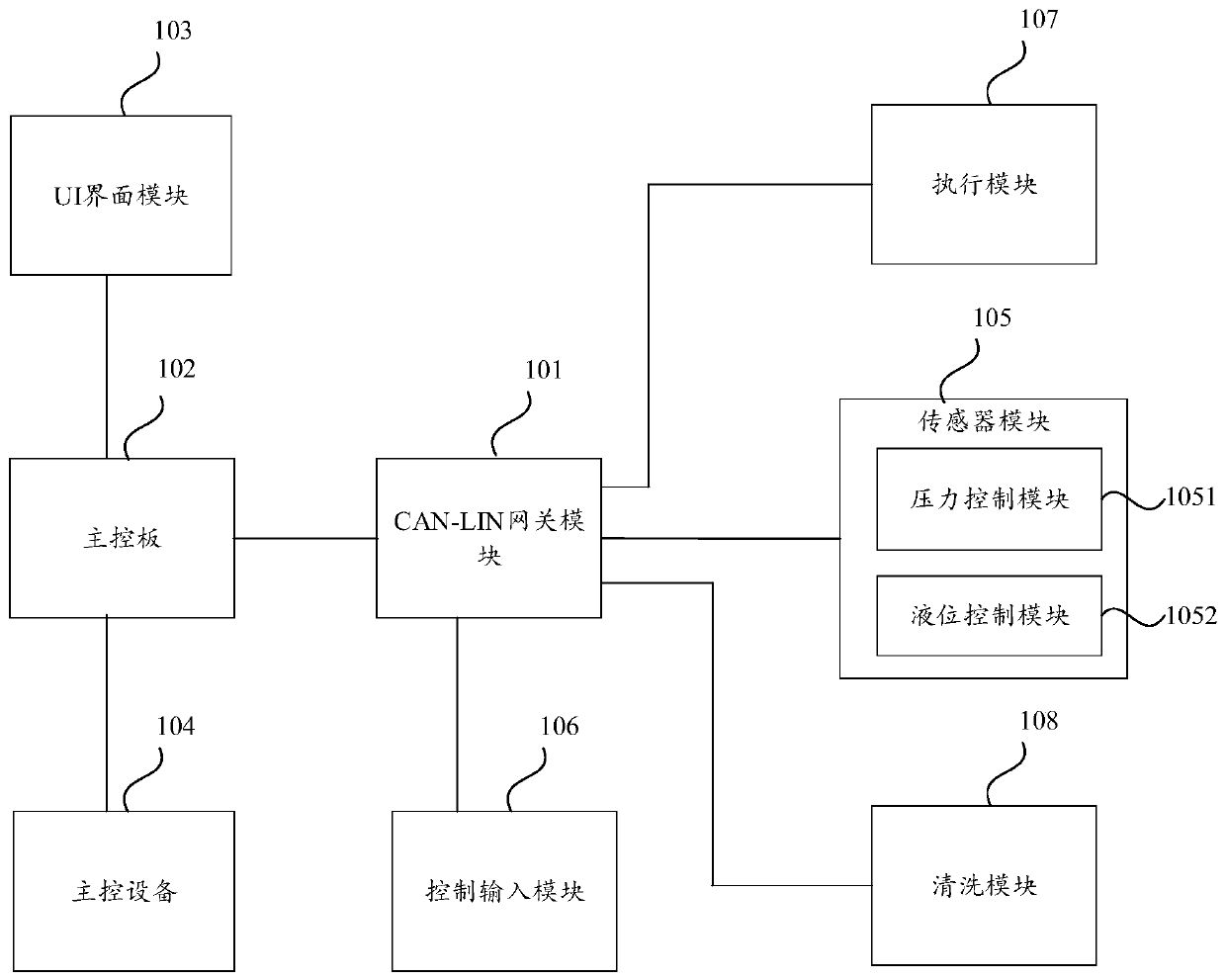

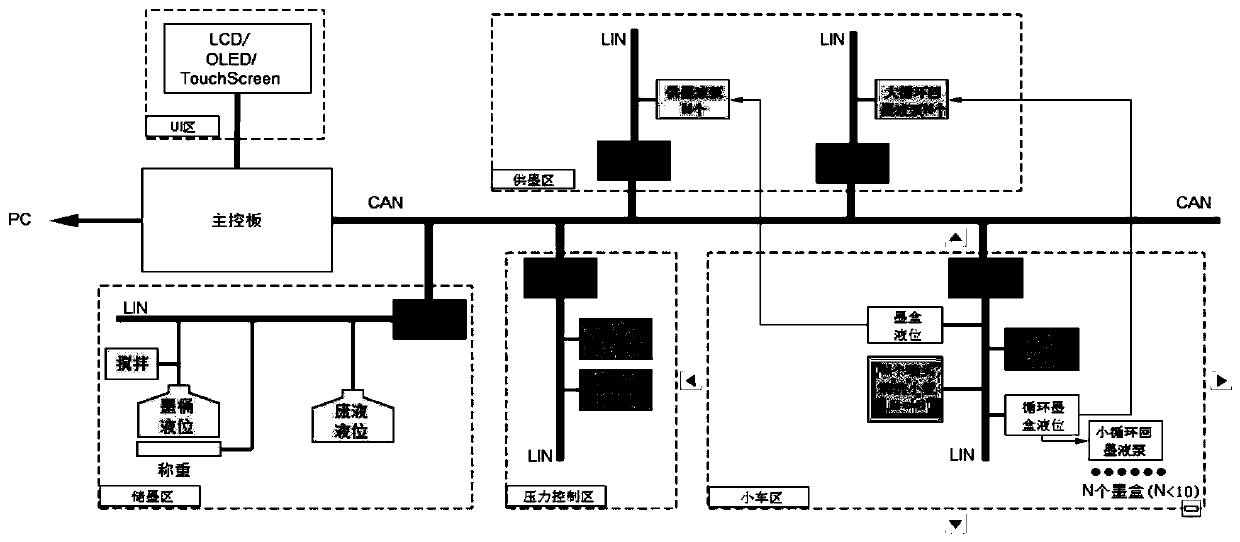

[0039] figure 1 A schematic structural diagram of a negative pressure ink system based on the CAN-LIN protocol provided by an embodiment of the present invention. refer to figure 1 , the system specifically may include: a CAN-LIN gateway module 101 , a main control board 102 , a UI interface module 103 , a main control device 104 , a sensor module 105 , a control input module 106 , an execution module 107 and a cleaning module 108 .

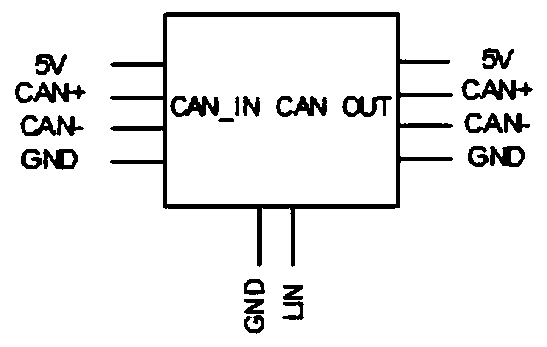

[0040] Wherein, the CAN-LIN gateway module 101 is used to realize the CAN agreement to the LIN agreement, and, the conversion of the LIN agreement to the CAN agreement, each module is connected with the CAN bus through the LIN bus and the described CAN-LIN gateway module; To collect the state information of each module, and report the state information to the UI (User Interface, user interface) interface module 103 and the main control device 104; the sensor module 105 includes a pressure control module 1051 and a liquid level control module 105...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com