Decorative ink printing technology allowing direct gold stamping

A decorative ink, a direct technology, applied in the printing field, can solve the problems of high requirements for the underlying ink, high condition requirements, hot stamping, etc., and achieve the effect of strong three-dimensional effect, rich color effect, and improved grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

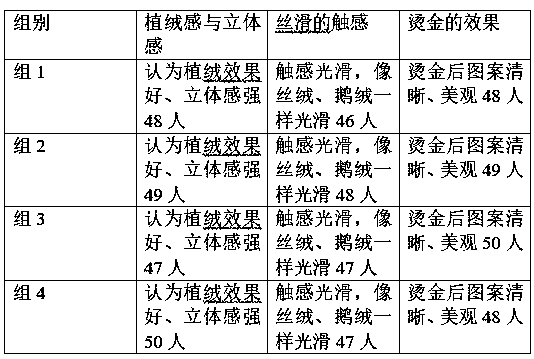

Examples

Embodiment 1

[0022] The present invention is a decorative ink printing process that can be directly bronzed, comprising the following steps:

[0023] (1) For plate making and paper selection, laser gravure printing is used for plate making, and the depth of plate making is 35 microns;

[0024] (2) Print ink on paper, in order to ensure the quality of ink printing, the viscosity of the ink is 21s, and finally print a layer of flocking varnish, the flocking varnish can be water-based flocking varnish, and the water-based flocking varnish The viscosity of the oil is 17s;

[0025] (3) Carry out bronzing at 90°C, and then solidify and dry at 100°C. The speed of bronzing is 2200 sheets / hour.

Embodiment 2

[0027] The present invention is a decorative ink printing process that can be directly bronzed, comprising the following steps:

[0028] (1) For plate making and paper selection, laser gravure printing is used for plate making, and the depth of plate making is 40 microns;

[0029] (2) Print ink on paper, in order to ensure the quality of ink printing, the viscosity of the ink is 30s, and finally print a layer of flocking varnish, the flocking varnish can be water-based flocking varnish, and the water-based flocking varnish The viscosity of the oil is 23s;

[0030] (3) Foil stamping at 125°C, and then curing and drying at 110°C. The stamping speed is 2500 pieces / hour.

Embodiment 3

[0032] The present invention is a decorative ink printing process that can be directly bronzed, comprising the following steps:

[0033] (1) For plate making and paper selection, laser gravure printing is used for plate making, and the depth of plate making is 38 microns;

[0034] (2) Print ink on paper, in order to ensure the quality of ink printing, the viscosity of the ink is 25s, and finally print a layer of flocking varnish, the flocking varnish can be water-based flocking varnish, and the water-based flocking varnish The viscosity of the oil is 20s;

[0035] (3) Foil stamping at 100°C, and then curing and drying at 105°C. The stamping speed is 2300 sheets / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com