High-efficiency nitrogen and phosphorus removal system for treating aquaculture tail water

A technology for nitrogen and phosphorus removal and aquaculture, applied in the field of high-efficiency nitrogen and phosphorus removal systems, can solve the problems of polluting the surrounding water environment, secondary pollution, and high treatment costs, and achieve no secondary pollution in the amount of sludge produced and degradation of organic matter Reduce and efficiently remove phosphorus and nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

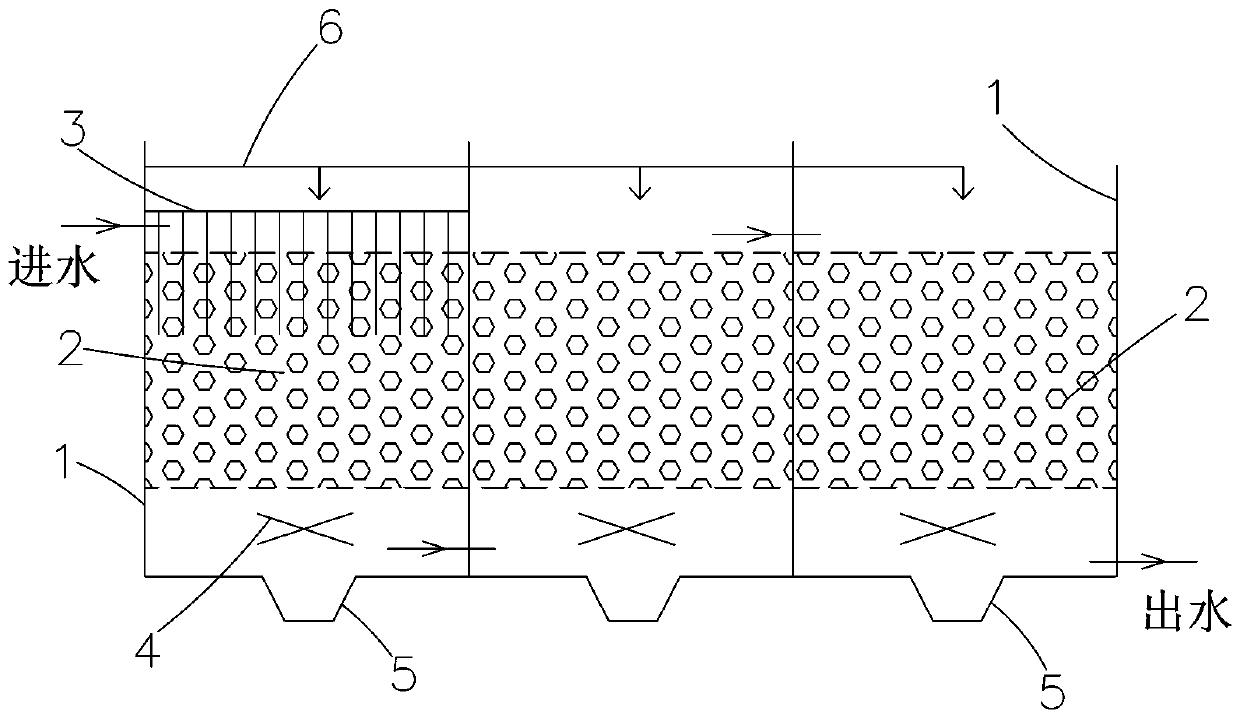

[0020] refer to figure 1 , the present invention relates to a high-efficiency denitrification and phosphorus removal system for treating aquaculture tail water. The system includes a tail water treatment biological filter 1, a suspension filler 2, a DC cathode and anode electrode array combination 3, an electric stirring device 4 and a carbon source supplement device, the suspended filler 2 is set in the tail water treatment biofilter 1, the DC cathode and anode electrode array combination 3 is set on the upper part of the tail water treatment biological filter 1, and the electric stirring device 4 is set in the tail water treatment biofilter 1 The bottom of the tail water treatment biological filter 1, the bottom of the tail water treatment biological filter 1 is provided with a sludge bucket 5, the electric stirring device 4 is arranged above the sludge bucket 5, and the carbon source replenishment device passes through Pipeline 6 is connected to tail water treatment biofilt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com