Complex organic acid descaling and cleaning agent and application thereof

A cleaning agent and organic acid technology, applied in the field of composite organic acid descaling cleaning agents, to achieve the effect of promoting peeling and dissolving, good ability to peel off scale layer and dissolving scale layer, and prevent pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 5kg of technical grade glycolic acid solution (70% by mass), and 1.875kg of technical grade formic acid solution (80% by mass), and pour them into a container with a volume of 150L. Use a glass cup to slowly inject 91.7L of desalinated water, and continuously stir the solution while injecting desalinated water to promote the miscibility of acid and water. Weigh food-grade citric acid solids (in C 6 h 8 o 7 Total) 1kg and 0.5kg of acetylacetone are dissolved in the glycolic acid+formic acid solution, and the solid is fully dissolved by stirring continuously. The acid solution after uniform mixing is the ternary compound organic acid cleaning agent of the present invention.

Embodiment 2

[0025] Clean the scaled tube samples of the supercritical boiler with compound organic acid descaling cleaning agent and common cleaning agent respectively. The cleaning temperature is 85°C and the cleaning time is 6 hours. The concentration of each cleaning agent is as follows:

[0026] 1. No. cleaning agent: for the compound organic acid descaling cleaning agent of embodiment 1 preparation: 3.5% glycolic acid+1.5% formic acid+1% citric acid (with C 6 h 8 o 7 Total) + 0.5% acetylacetone co-solvent.

[0027] No. ② cleaning agent: citric acid: concentration 6%, add ammonia water to adjust pH to 3.7±0.2; specific preparation method is: weigh 6kg (in C 6 h 8 o 7 Meter) solid food-grade citric acid, dissolved in 94L of demineralized water, and slowly stirred with a glass rod to promote the dissolution of citric acid. Stop adding ammonia water at 0.2, and the cleaning agent No. ② is prepared.

[0028] ③No. cleaning agent: glycolic acid+formic acid: 3.5% glycolic acid+1.5% for...

Embodiment 3

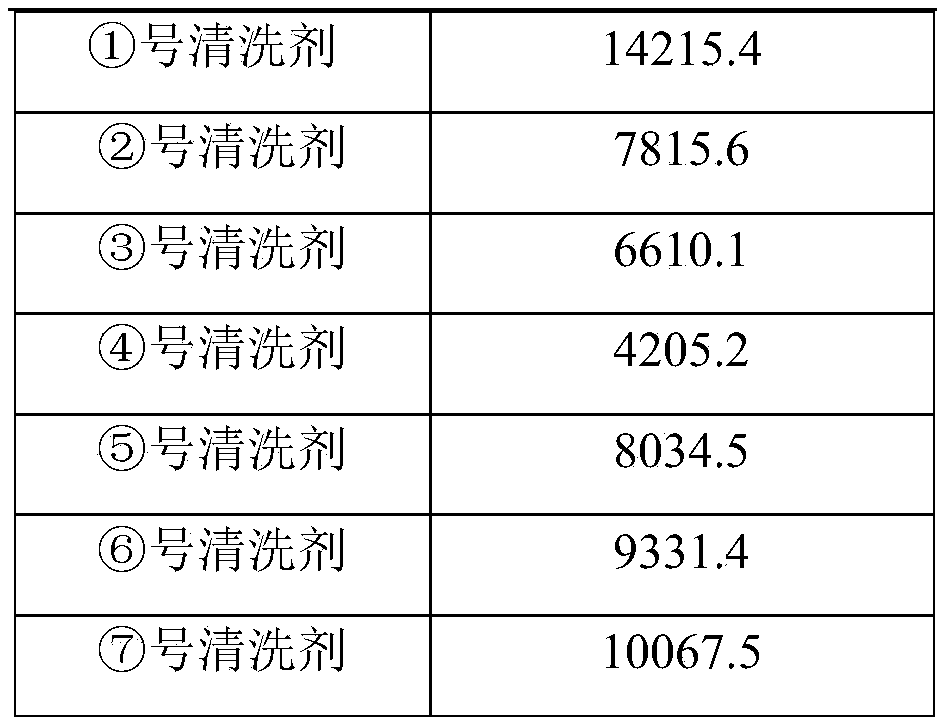

[0037] Add the iron scale scraped off from the boiler tube wall to the cleaning solution after cleaning in Example 2, until the cleaning solution appears iron slag insoluble or precipitated out, measure the concentration of iron ions in the cleaning solution at this time, this concentration is each cleaning solution The limit concentration of the agent to dissolve iron scale, the results are shown in Table 2. It can be seen from the results that the scale dissolution limit of the compound organic acid descaling cleaning agent exceeds 14000mg / L, and the scale dissolution ability is obviously stronger than the other six other cleaning agents.

[0038] Table 2 Comparison of scale dissolution limit concentration of various cleaning agents

[0039]

[0040]

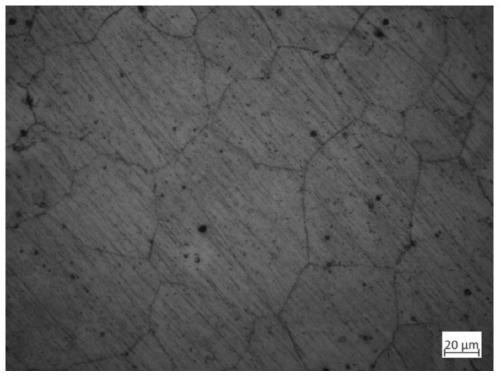

[0041] Carry out metallographic detection to the boiler pipeline after cleaning with composite organic acid descaling cleaning agent in embodiment 2, metallographic photo is as follows figure 1 shown. It can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com