Purlin-free wall face colorful steel plate system and mounting method thereof

An installation method and color steel plate technology, applied in the direction of walls, building components, climate change adaptation, etc., can solve the problems of unreliable fixing effect, waste of materials, and increased cost, so as to avoid hidden dangers of rework and subsequent use, ensure accuracy, reduce The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

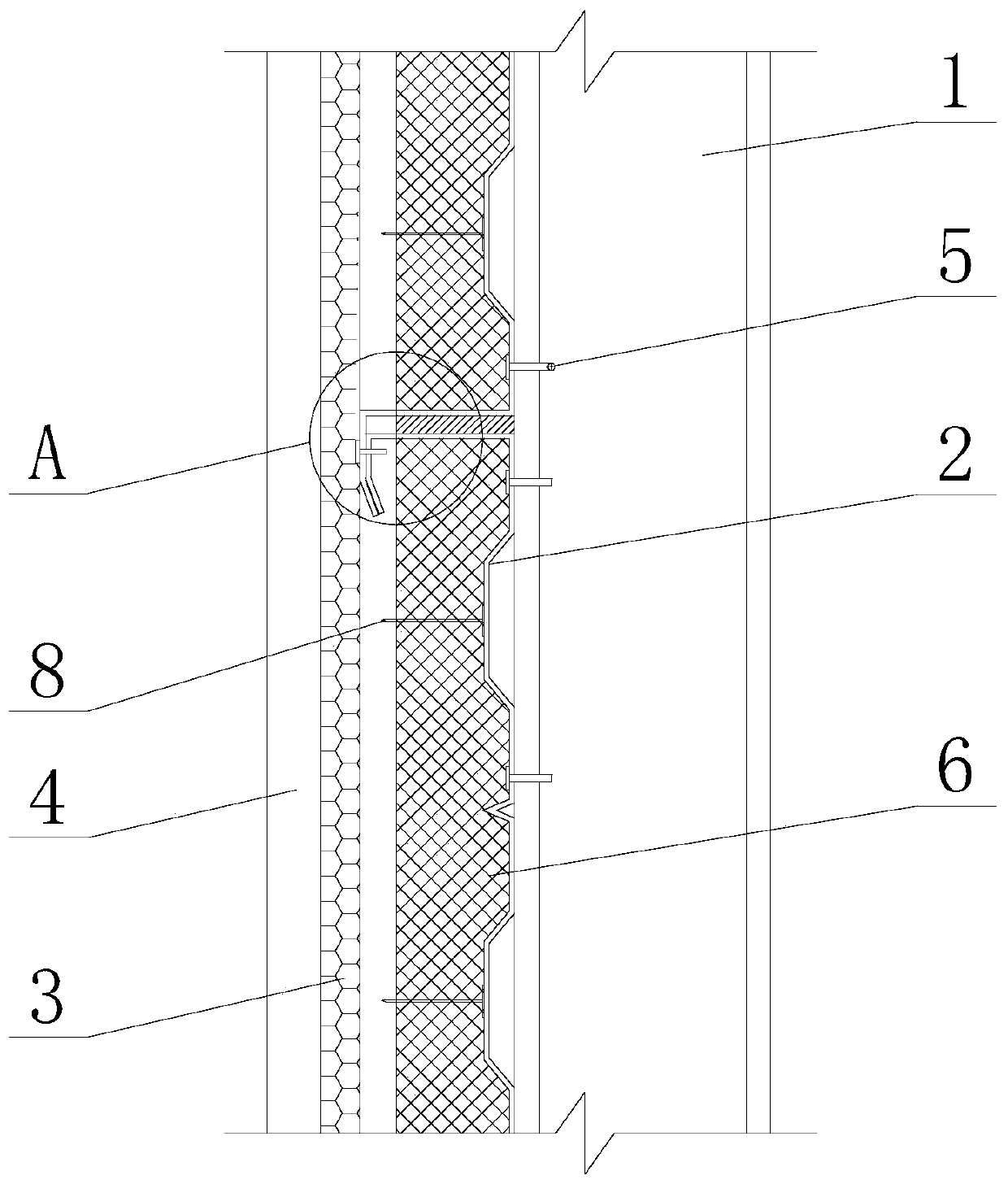

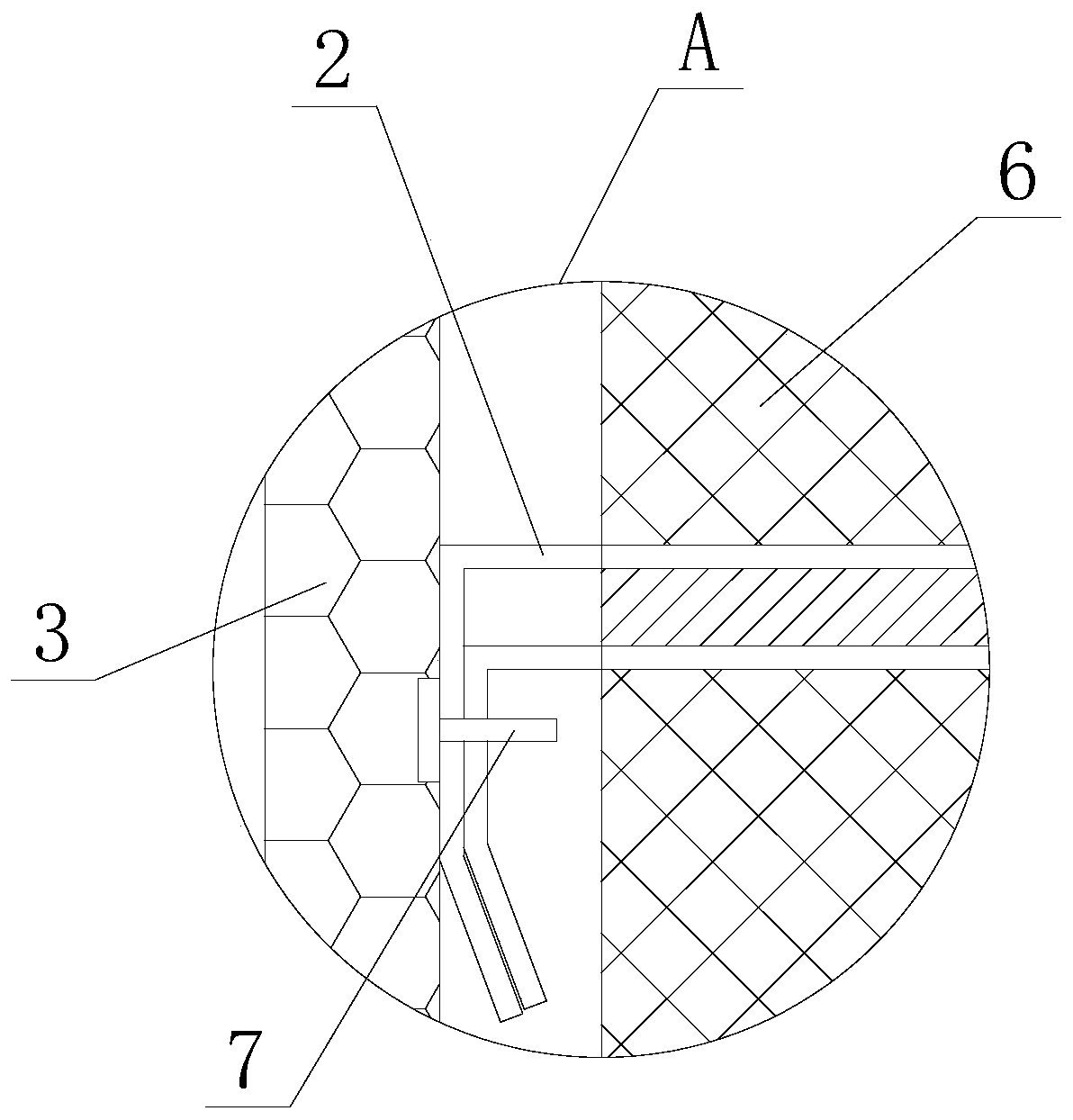

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

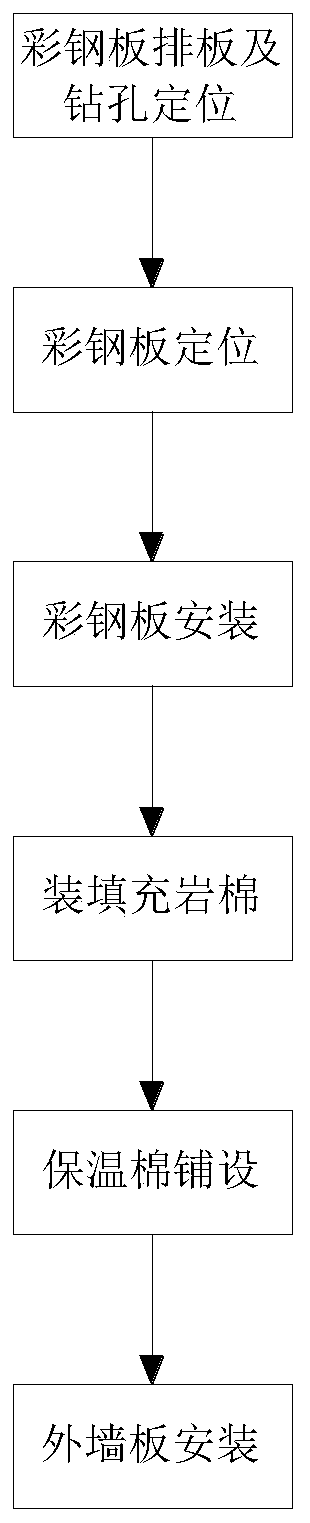

[0027] like Figure 1-2 As shown, a purlin-free wall color steel plate system includes vertically arranged steel columns 1, color steel plates 2, thermal insulation cotton 3 and exterior wall panels 4, color steel plates 2 are box-shaped, and there are several color steel plates 2, Each color steel plate 2 is sequentially arranged on the steel column 1 from bottom to top, the trough of the color steel plate 2 and the flange plate of the steel column 1 are connected by self-tapping screws 5, and two adjacent color steel plates 2 overlap each other, And form a connecting part, between two adjacent connecting parts, there is filled rock wool 6, the thermal insul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap