Down-hole video instrument

An instrument and video technology, which is applied in the field of downhole video instruments, can solve the problems of not being able to meet the requirements of high temperature and high pressure, not being able to transmit in real time, and not being able to realize real-time transmission of high-definition images with a large amount of data, and achieve simple structure, expanded use range, and reduced expenses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

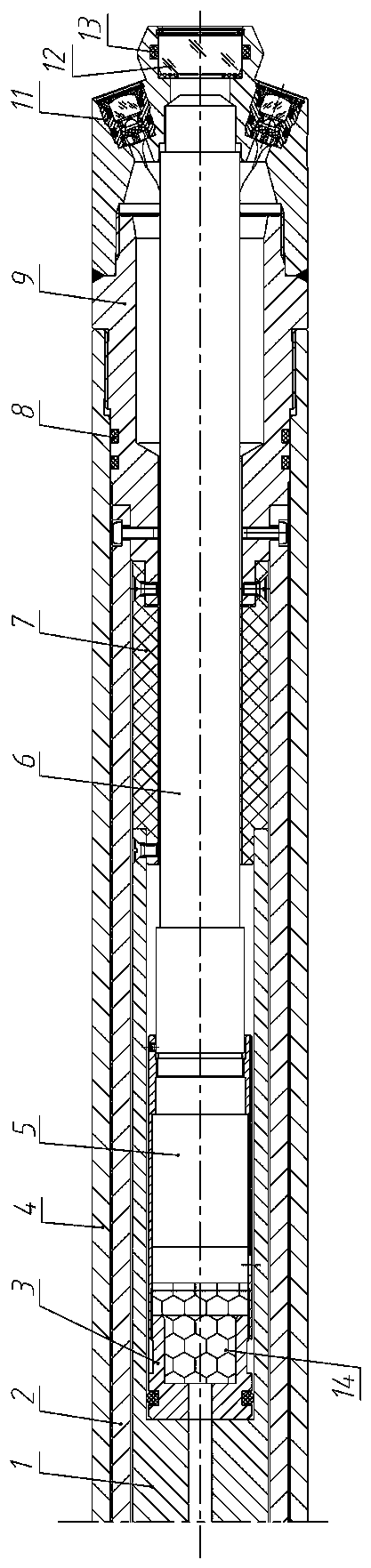

[0028] The present invention is a downhole video instrument, comprising a pressure-bearing outer tube 4 and a hollow lower joint 9, the lower joint 9 is connected to one end of the pressure-bearing outer tube 4, and the end of the pressure-bearing outer tube 4 connected to the lower joint 9 is The end of the pressure-bearing outer tube 4, and the other end is the head end of the pressure-bearing outer tube 4; the end of the lower joint 9 far away from the pressure-bearing outer tube 4 is also connected with a plug;

[0029] It also includes a thermal insulation tube 2, which is a hollow columnar thermal insulation tube 2, the thermal insulation tube 2 is coaxially connected in the pressure-bearing outer tube 4, and one end of the thermal insulation tube 2 is fixedly connected with the lower joint 9; the thermal insulation tube 2. One end connected to the lower joint 9 is the end of the insulation pipe 2, and the other end is the head end of the insulation pipe 2;

[0030] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com