Natural ventilation countercurrent type cooling tower air energy power generation device

A power generation device and natural ventilation technology, applied in wind power generation, installation/supporting configuration of wind turbines, water shower coolers, etc., can solve the problems of low cooling tower cooling efficiency, large cooling margin, etc., to improve antifreeze performance, The effect of reducing power consumption and reducing draft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

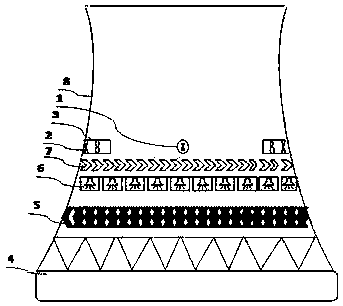

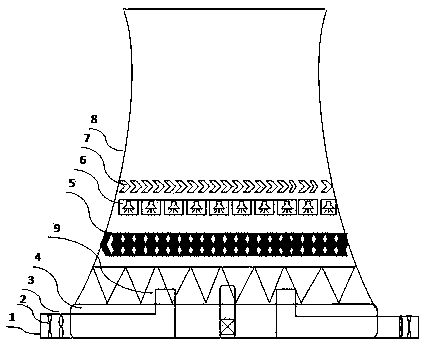

[0027] Embodiment 1 of the present invention: such as figure 1 with figure 2 As shown, this kind of natural ventilation counter-flow cooling tower air energy power generation device is provided with an air inlet system above the spray device 6 in the cooling tower, and the air inlets 1 of the four air inlet systems are arranged on the cooling tower barrel 8, which is Circumferentially symmetrically arranged. The air inlet pipe extends along the inspection channel in the tower to the inside of the tower tube, and the air inlet volume of each air inlet 1 is the same.

[0028] Install a wind generator 3 at the air inlet 1 of the air inlet pipe. The wind generator 3 preferably uses a breeze to start the generator and send power to the grid. As long as the air flow is used as power, the driving equipment of the wind generator 3 can be blades The fan can also be an axial fan or other forms, which does not affect the effect of this application; the total output power of the power gener...

Embodiment (2)

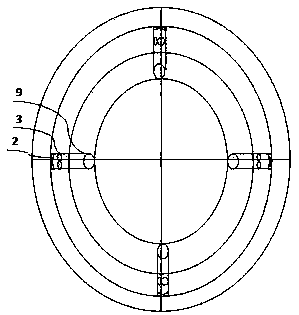

[0038] Embodiment (2) of the present invention: such as image 3 As shown, this kind of natural ventilation countercurrent cooling tower air energy power generation device is provided with an air inlet system above the spray device 6 in the cooling tower, and the air inlets 1 of the four air inlet systems are arranged outside the cooling tower, in a circumferential direction Symmetrically arranged, the air inlet pipe is arranged in the cooling tower pool 4 and extends to the central area of the cooling tower, so that air can effectively enter the inside of the cooling tower barrel 8. This arrangement is used in the case of closing the cooling tower inner circle to spray water in winter. The air outside the tower enters into the tower tube 8 of the cooling tower smoothly, which reduces the air density inside the tower tube 8, increases the air outflow resistance, reduces the cooling tower's pumping force, and reduces the water spraying area from the lower part of the cooling to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com